Pneumatic tire

A technology for pneumatic tires and tread parts, applied to tire parts, tires, wheels, etc., can solve problems such as rupture of protective rubber sheets and deterioration of tire uniformity, achieve flow suppression, reduce the generation of decomposition gas, and prevent uniformity the worsening effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

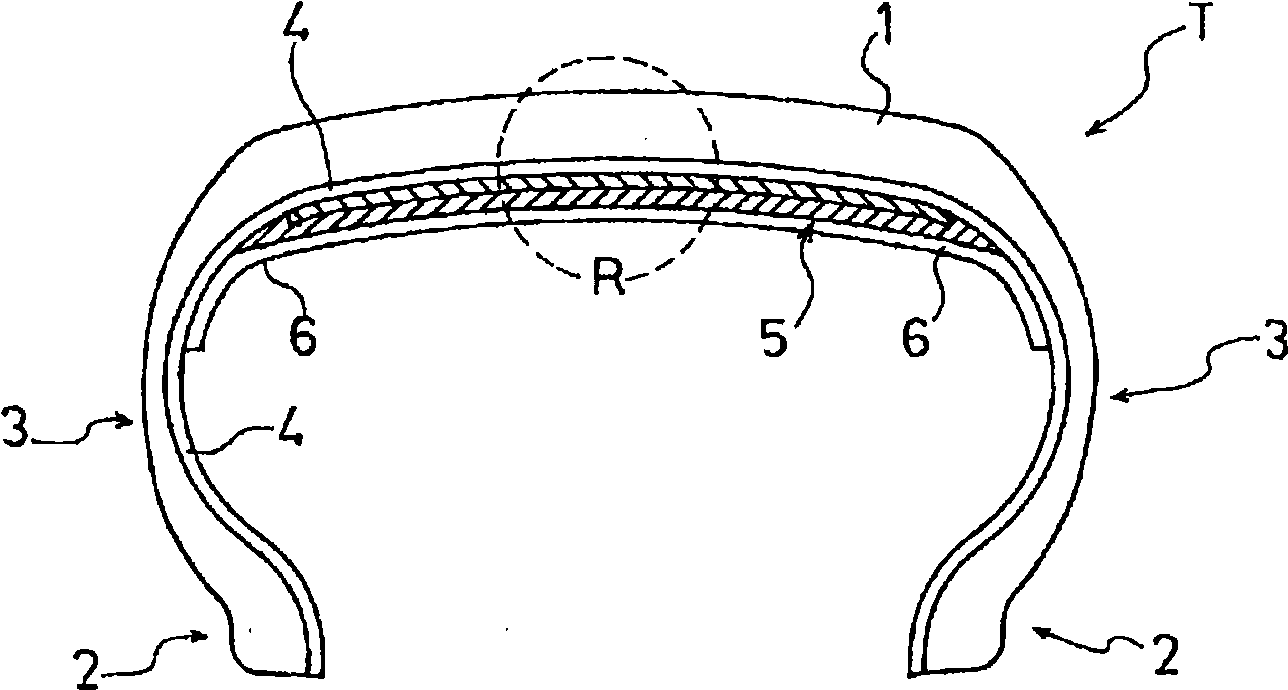

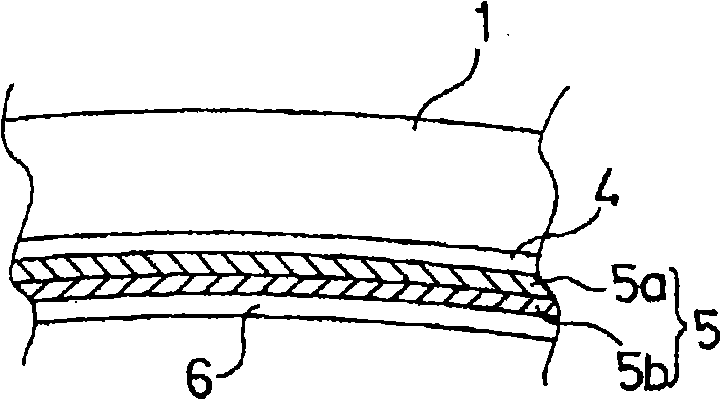

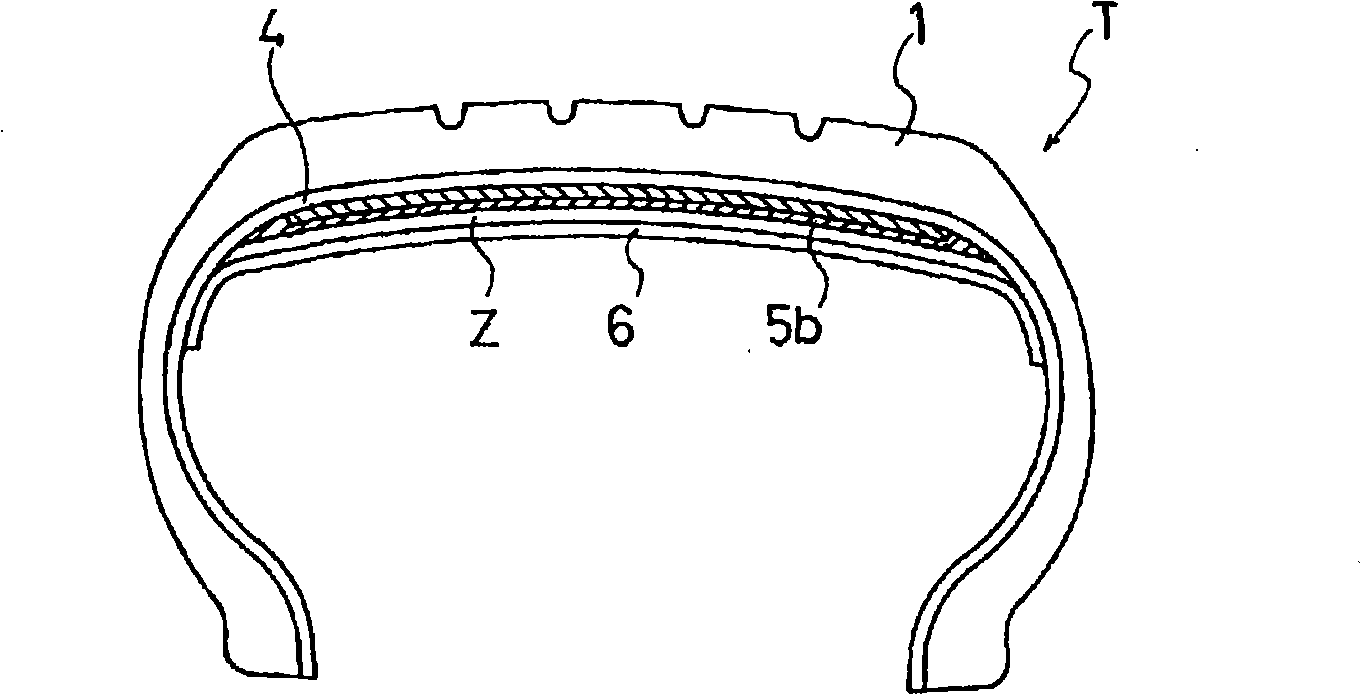

[0042] The tire size and the structure of the adhesive sealant layer 5 were different as shown in Table 1, and conventional tires (conventional examples 1 and 2), inventive tires (examples 1 and 2), and comparative tires (comparative examples) were produced. In addition, the structure of each tire is set as figure 1 As shown in the adhesive sealant material, a rubber composition composed of a rubber component decomposed by peroxide is used.

[0043] For these five types of tires, the sealing properties and uniformity were evaluated by the following test methods, and the results are combined and described in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com