Safety protection device of electrothermal film heater

A technology of safety protection device and electric heating film, applied in electric heating devices, instruments, electrical components, etc., can solve problems such as high thermal energy conversion efficiency, electrical safety accidents, and limitation of operating temperature conduction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] The temperature control safety protection device of the present invention comprises an NTC temperature controller with a negative temperature coefficient thermistor as a temperature sensor and a jump-type bimetal temperature controller.

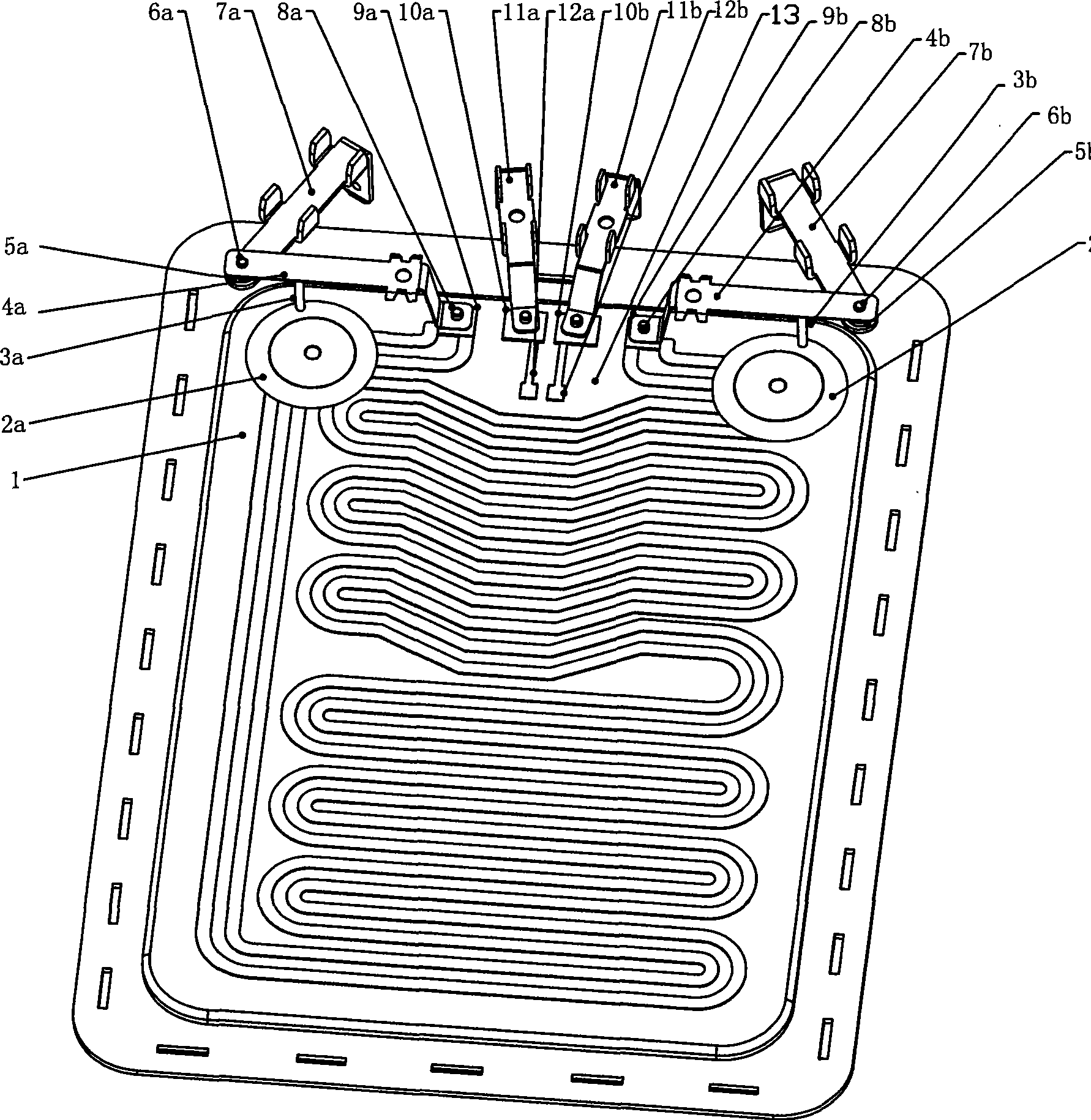

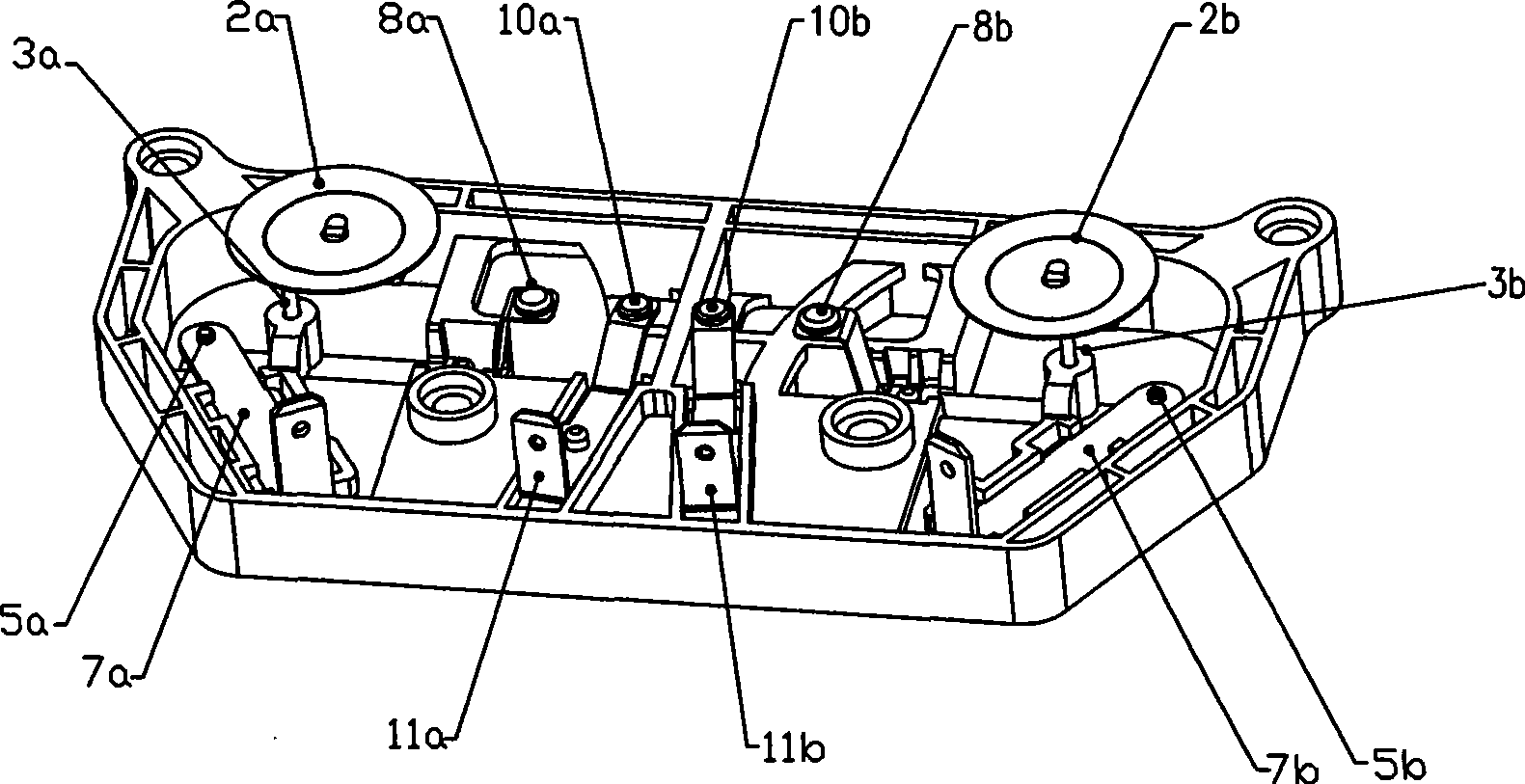

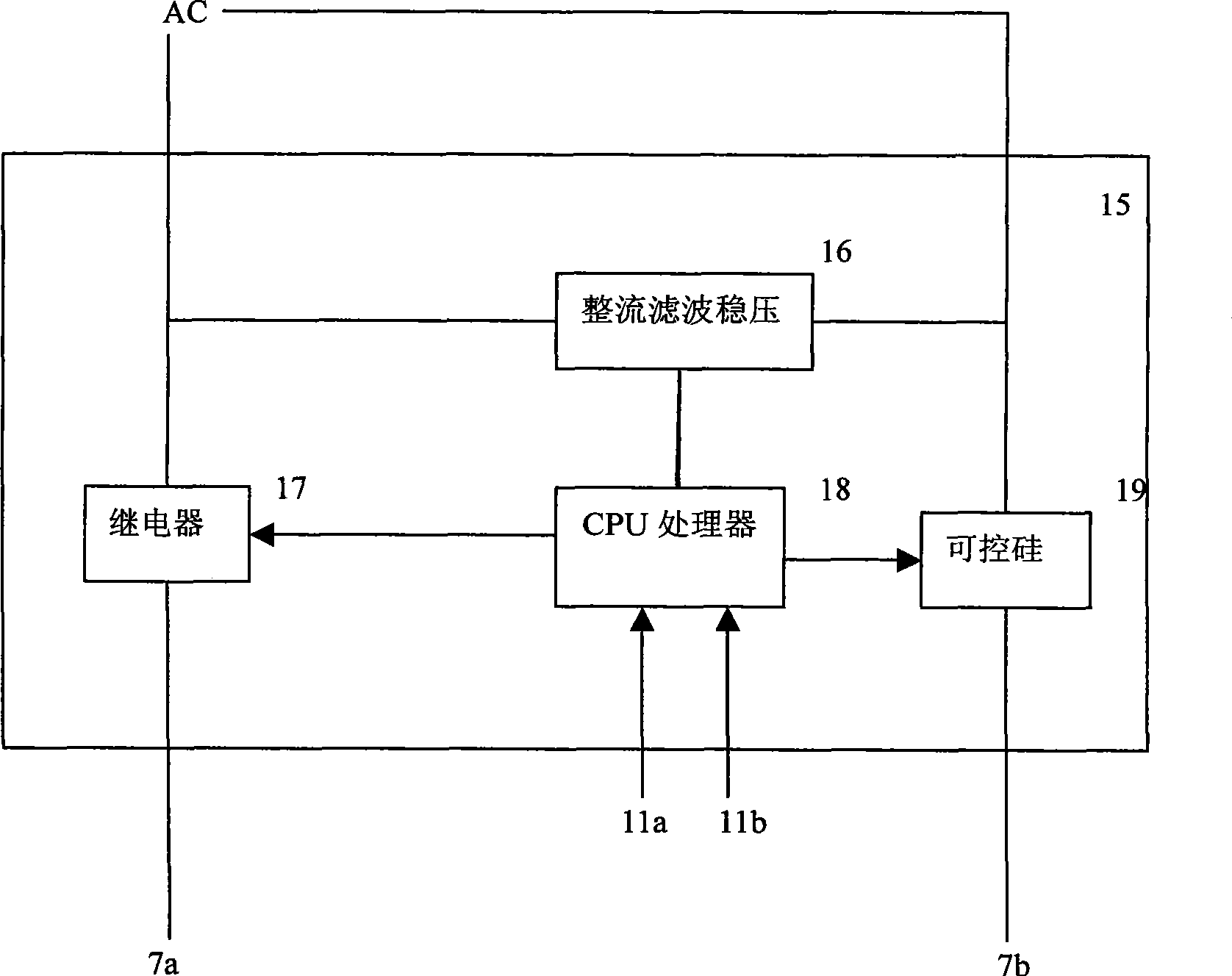

[0015] figure 1 The shown NTC temperature controller part includes two thermistors 12 arranged side by side in the middle of the upper end of the electrothermal film plate 1, wherein the left thermistor is 12a, the right thermistor is 12b, and the rear end of the thermistor 12 is left or right Thermistor patch 10a or 10b. Thermistor 12 is introduced into the microprocessor CPU input terminal through conductive sheet 11a or 11b, and thermistor 10a or 10b is a kind of negative temperature coefficient sensor, and its resistance value declines with the rise of temperature, so when electrothermal film plate 1 When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com