Anti-collapse oil casing and manufacturing method thereof

A technology of oil casing and manufacturing method, which is applied to casing, manufacturing tools, drilling pipes, etc., can solve the problem that the anti-collision performance of steel pipes cannot meet the oil field, and achieve the advantages of low cost, low residual stress and low alloy content of steel pipes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

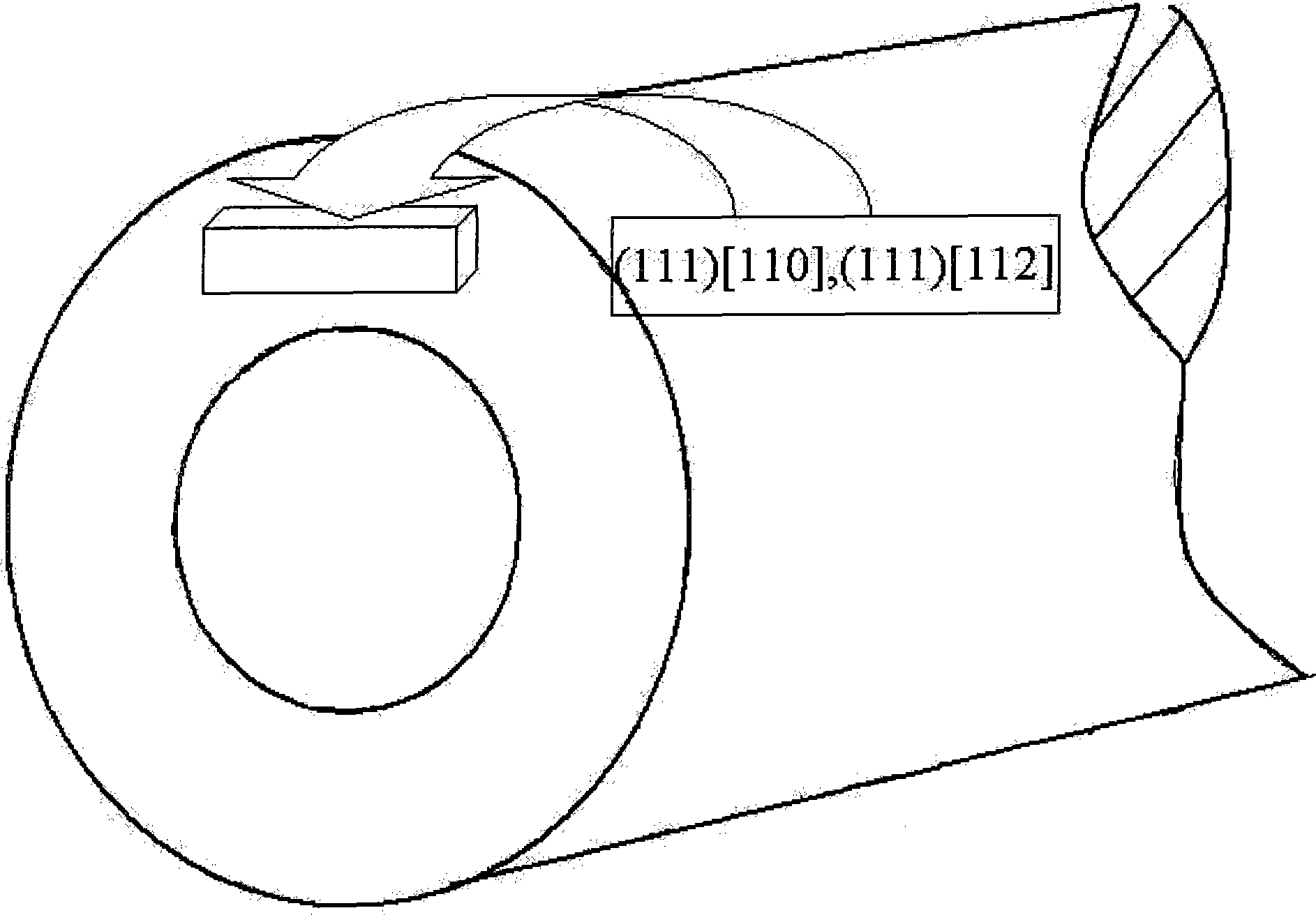

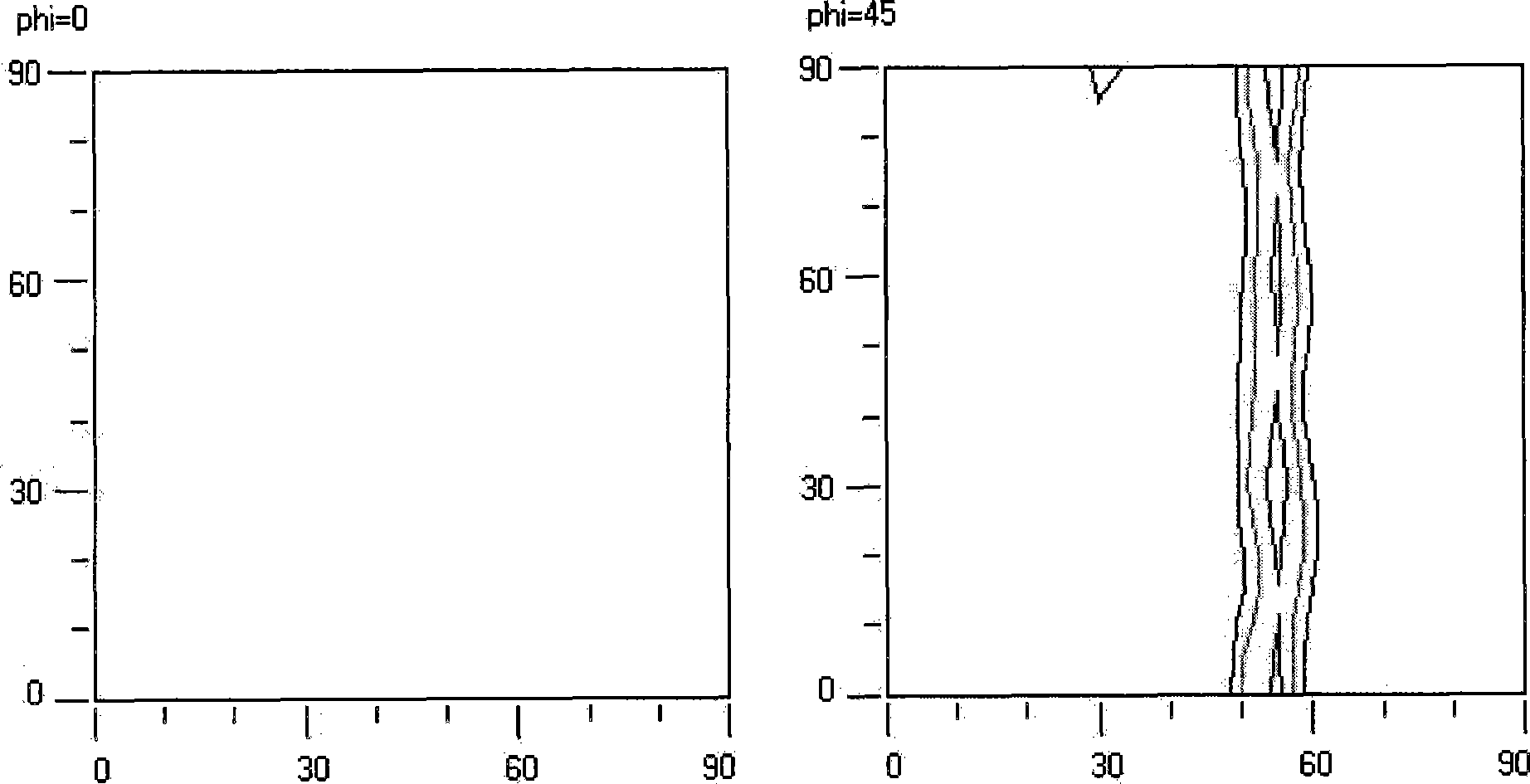

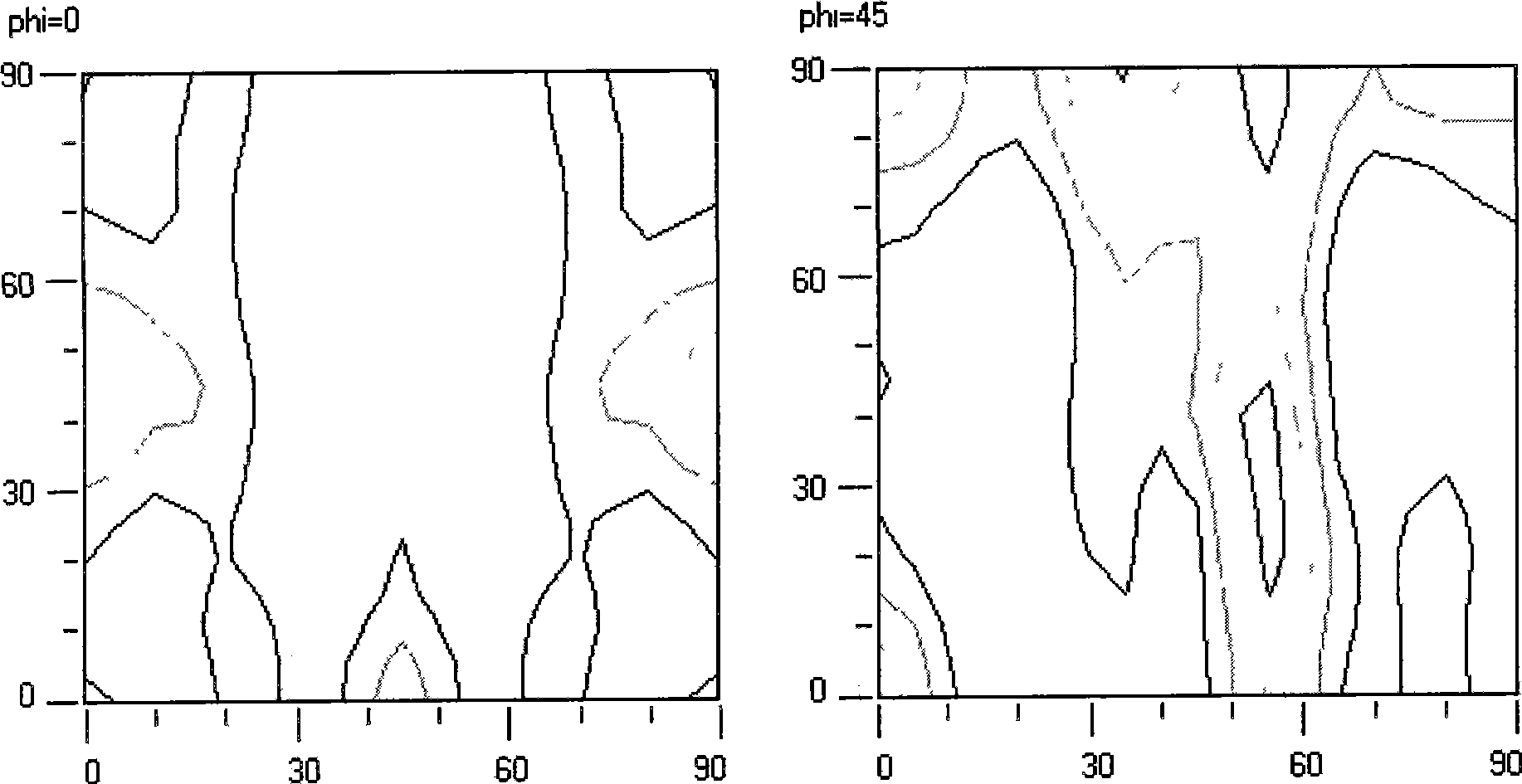

Image

Examples

Embodiment 1-8

[0057] See Table 3 for the weight percent distribution ratio of each chemical component in Examples 1-8 of the present invention.

[0058] Table 3 Examples and Comparative Examples Chemical Composition (wt.%)

[0059] C Mn Si P S Cr Mo V Ti Nb Cu Ni Al Ca B Zr Example 1 0.27 1.17 0.27 0.009 0.004 0.1 0.09 0.005 0.001 Example 2 0.28 1.50 0.30 0.010 0.006 0.2 0.18 0.02 0.01 0.04 0.004 Example 3 0.25 1.20 0.35 0.010 0.001 0.20 0.1 0.25 0.02 0.06 0.05 Example 4 0.24 0.20 0.25 0.012 0.004 0.51 0.7 0.07 0.05 0.02 0.003 Example 5 0.34 0.40 0.20 0.013 0.005 2.5 0.8 0.13 0.04 0.02 0.008 0.009 Example 6 0.18 0.49 0.29 0.011 0.005 0.97 0.6 0.10 0.05 0.04 0.031 0.005 0.0030 Example 7 0.25 0.91 0.50 0.013 0.003 1.1 0.36 0.02 0.03 0.04 0.50 0.50 0.027 0.004 Example 8 0.27 0.39 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com