Method for synthesizing betaine

A betaine and synthesis reaction technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low utilization rate of equipment, frequent operation of discharging materials, high production cost, etc., and achieve the improvement of raw material utilization rate, The effect of reducing the pollution of three wastes in the process and improving the utilization rate of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

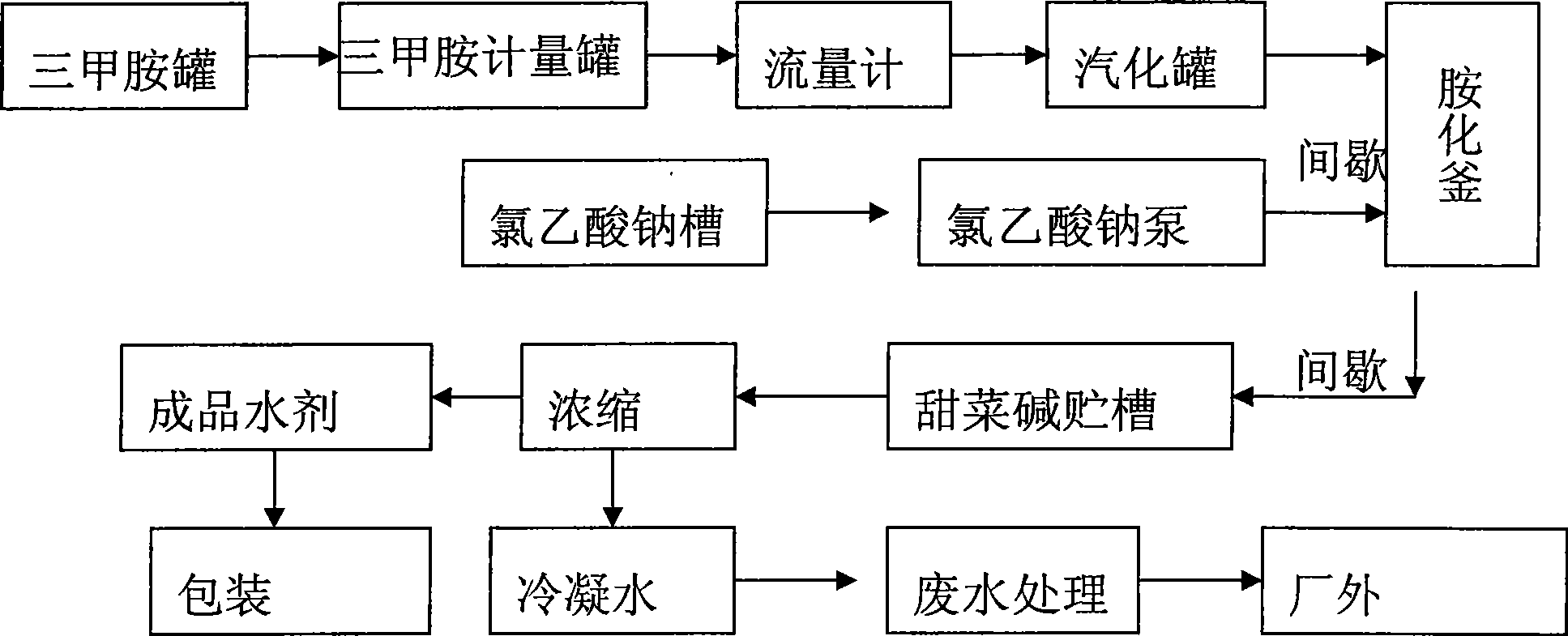

Method used

Image

Examples

Embodiment 1

[0016] Example 1, a method for synthesizing betaine, using trimethylamine and magnesium chloroacetate at a molar ratio of 1.02:1 for amination synthesis, the synthesis reaction temperature is controlled at 53°C, the pH value is controlled at 8.5, and the synthesis time is 3 hours. Among them, magnesium chloroacetate is generated by neutralization of chloroacetic acid and magnesium carbonate, and the neutralization reaction temperature is controlled at 40°C

Embodiment 2

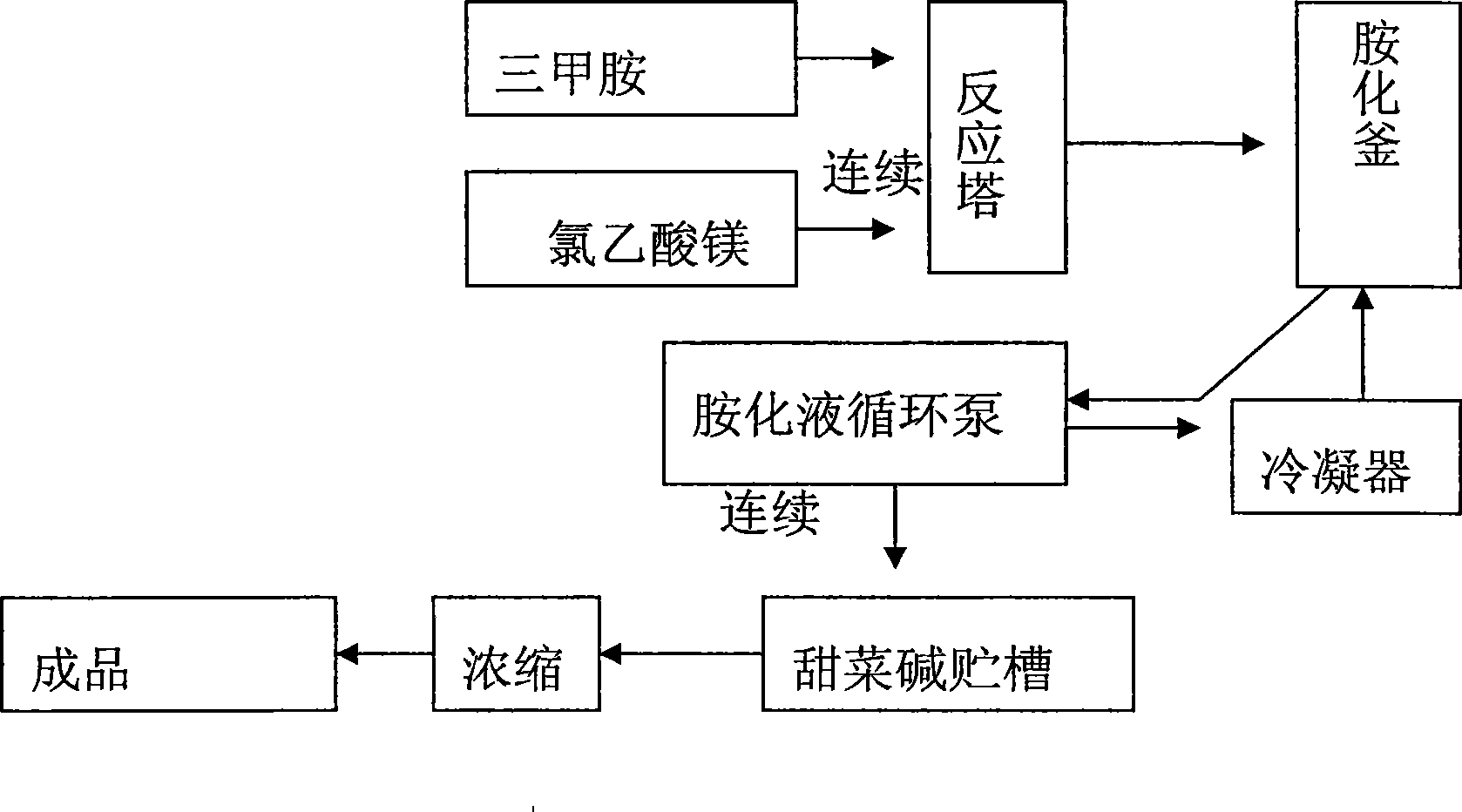

[0017] Embodiment 2, a kind of method for synthesizing betaine, adopts continuous production method, is connected by pipeline successively by reaction tower, amination kettle, amination liquid circulation pump, betaine storage tank, and trimethylamine and chloroacetic acid are respectively placed on the reaction tower The feed pipe of magnesium and the circulating pump of the aminated solution are connected to the reaction tower after being connected to the condenser through a circulation pipeline, and a pH meter is installed on the circulation pipeline.

[0018] Use trimethylamine and magnesium chloroacetate at a molar ratio of 1.03:1 for amination synthesis, the synthesis reaction temperature is controlled at 55°C, the pH value is controlled at 8.5, and the synthesis time is 2.5 hours, wherein the magnesium chloroacetate is neutralized by chloroacetic acid and magnesium carbonate Formation, the temperature of the neutralization reaction in the neutralization tank is controlle...

Embodiment 3

[0019] Example 3, reference example 2, the molar ratio of trimethylamine to magnesium chloroacetate is 1.025:1, the synthesis reaction temperature is controlled at 40°C, the pH value is controlled at 8, the synthesis time is 4 hours, and chloroacetic acid and magnesium carbonate are neutralized Magnesium chloroacetate is generated, and the temperature of the reaction in the neutralization tank is controlled at 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com