Method for producing polyaluminium chloride

A technology of polyaluminum chloride and its production method, which is applied in the fields of aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., and can solve problems such as failure to detect new technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

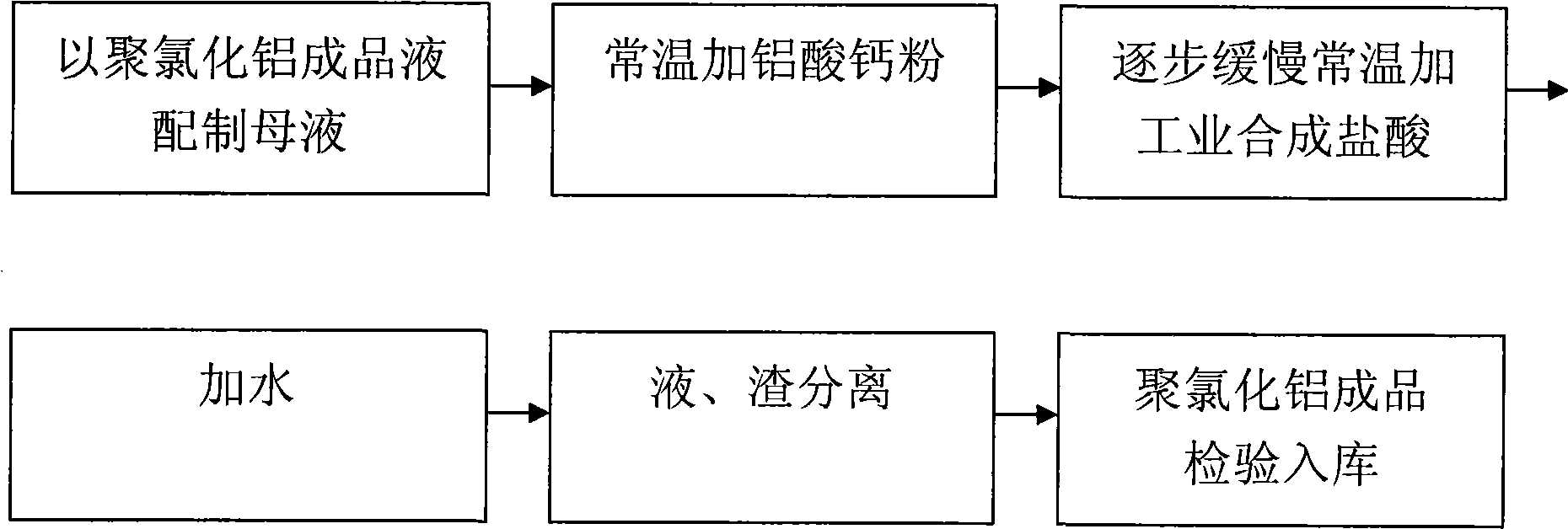

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, with Al 2 o 3 Mass content is 10% total output 1 ton of liquid finished product meter, get polyaluminum chloride mother liquor 150kg, put into reaction vessel, add calcium aluminate powder (Al 2 o 3 Content 51~52%, acid-dissolving method) 170kg, then at normal temperature, add 110.5kg (mass ratio 0.65) of industrial hydrochloric acid converted into 100% mass concentration, when the temperature reaches 55 ℃, gradually add water 569.5kg, control the flow meter The temperature of the liquid in the reaction vessel is kept between 87°C and 100°C, and the liquid and slag are separated after 2 hours. This example adopts the pressure filtration method to obtain 980kg of finished product liquid and 20kg of waste residue. The finished liquid complies with GB15892-2003 standard.

Embodiment 2

[0030] Example 2, with Al 2 o 3 Mass content is 10% total output 1 ton of liquid finished product meter, get polyaluminum chloride mother liquor 400kg, put into reaction vessel, stir and add calcium aluminate powder (Al 2 o 3 Content 51~52%, acid-dissolving method) 126kg, normal temperature is added and converted into mass concentration and is 104.6kg (mass ratio 0.83) of industrially synthesized synthetic hydrochloric acid, when temperature reaches 55 ℃, add water 369.4kg, control flow rate requirement reaction solution temperature In the range of 87-100°C, after 2 hours, the liquid and slag will be separated. In this example, centrifugation is used to obtain 985kg of finished product liquid and 15kg of waste residue. The finished liquid complies with GB15892-2003 standard.

Embodiment 3

[0031] Embodiment 3, according to the above example, get mother liquor 200kg, put into reaction tank, stir and add calcium aluminate powder 164kg next time, normal temperature is added and converted into mass concentration and is 100% industrial synthetic hydrochloric acid 114.8kg (mass ratio 0.70), when reaction in the tank When the temperature reaches 60°C, add 521.2kg of water, and control the flow so that the temperature in the pool is within the range of 87-100°C. After 2.0 hours, the liquid and slag were separated. This example adopts the filter press method to obtain 980 kg of finished product liquid and 20 kg of waste residue. The finished liquid complies with GB15892-2003 standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com