Composite type biological emulsion splitter

A biological demulsifier, a composite technology, applied in the directions of microorganisms, microorganism-based methods, biochemical equipment and methods, etc., can solve the failure of large-scale application of biological demulsifiers, the large amount of chemical demulsifiers used, and the cost of use and research and development. increase and other issues, to achieve the effect of easy large-scale application, saving energy consumption, reducing use and research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment 1: The composite biological demulsifier in this embodiment is prepared by mixing 0.5-1.5 mg of chemical demulsifier, 550-650 mg of biological demulsifier, 2.5-3.5 mg of chemical demulsifier and the rest of distilled water per liter. The main component of the chemical demulsifier is polyoxypropylene polyoxyethylene propylene glycol ether; the biological demulsifier is the extracellular protein secretion of Bacillus mojavensis; the main component of the chemical demulsifier is polyethylene based polyquaternium salts.

[0009] The preparation of the biological demulsifier in the present embodiment: 1. Get Bacillus mojavensis and inoculate it in a liquid medium, and cultivate it for 24 hours at a temperature of 30 ± 2° C. and 140 r / min to obtain a seed solution; 2. 1. Inoculate the seed liquid in the nutrient solution of the fermenter at a volume ratio of 10%, and cultivate it for 24h under the condition of 30±2° C. to obtain the whole fermented liquid o...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the composite biological demulsifier is prepared by mixing 1 mg of chemical demulsifier, 600 mg of biological demulsifier, 3 mg of chemical demulsifier and the rest of distilled water per 1 L. made. Others are the same as in the first embodiment.

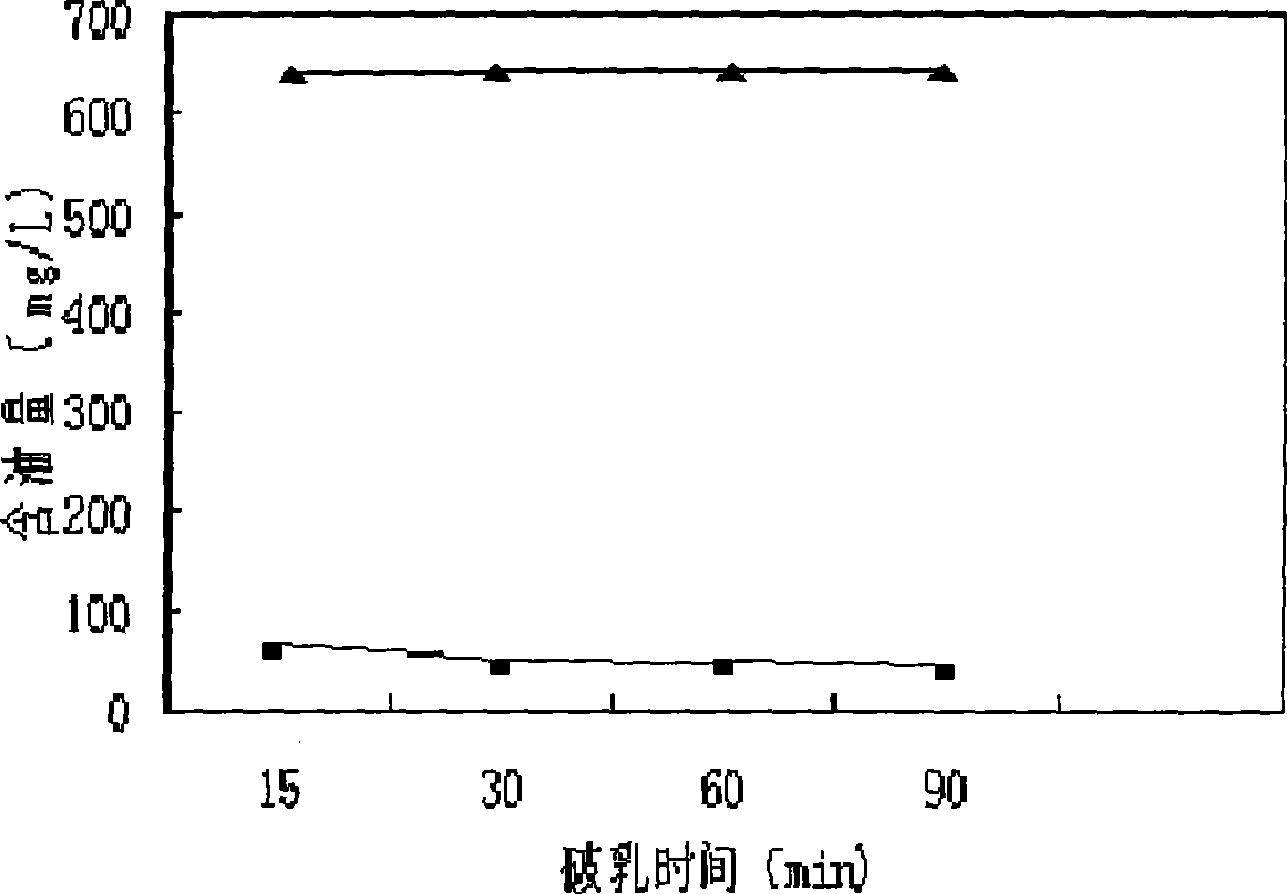

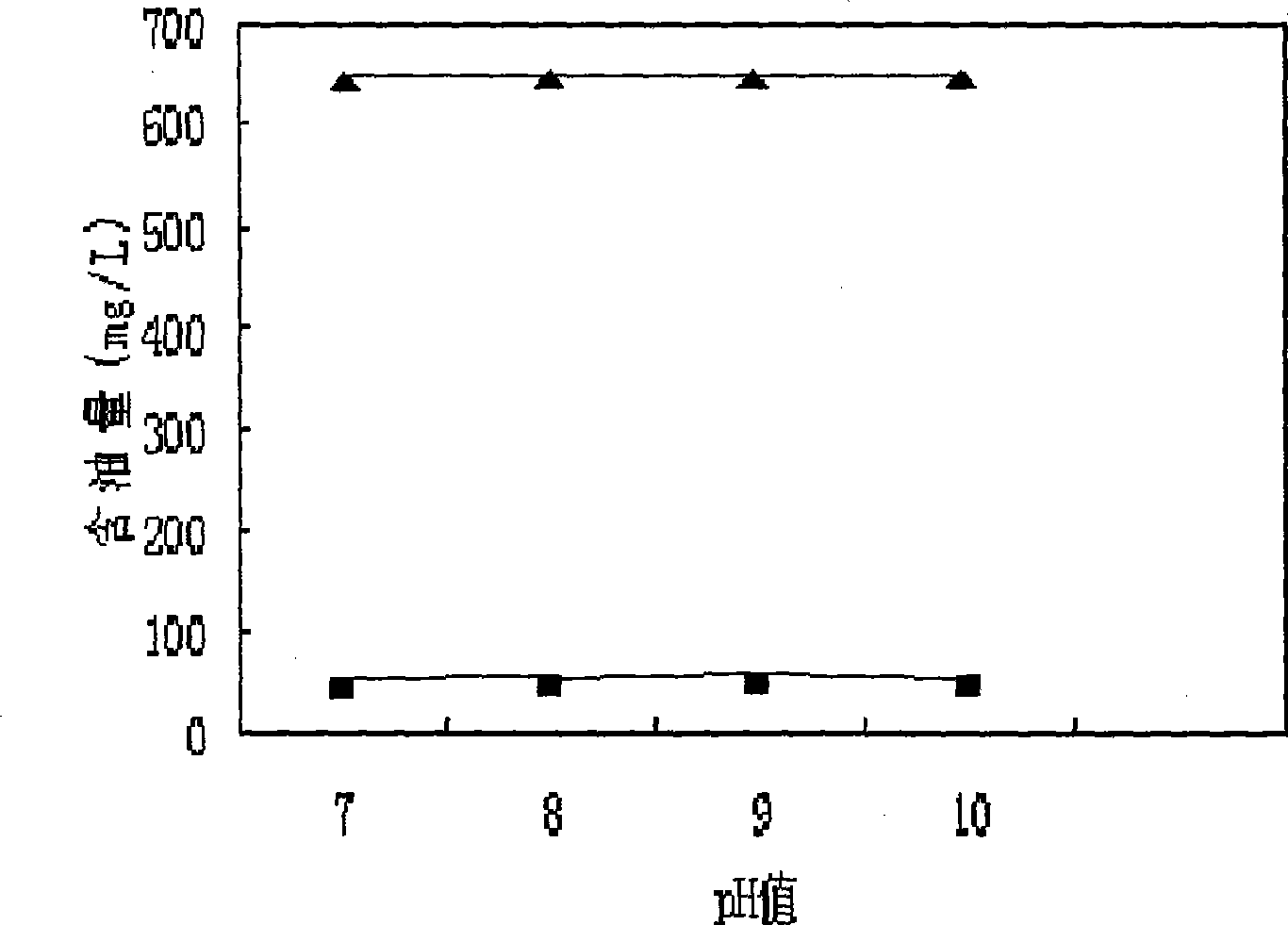

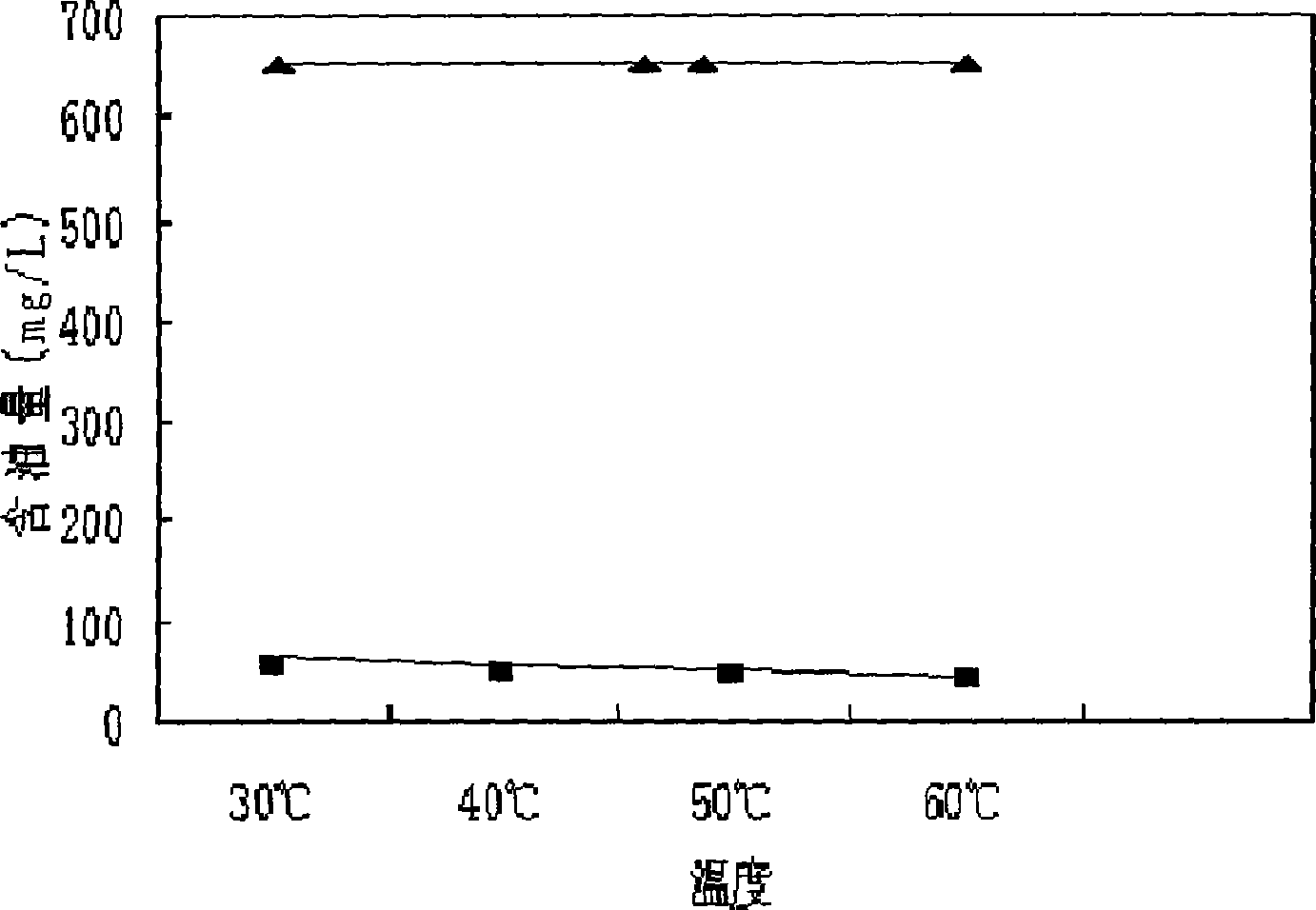

[0021] In this embodiment, the composite biological demulsifier is used to treat oilfield production fluid, and the test results are as follows figure 1 It is shown that with the prolongation of the demulsification time, the treatment effect of the composite biodemulsifier on the oilfield production fluid is better, and the oil content in the oilfield production fluid can be reduced by about 90% in 30 minutes; as figure 2 As shown, the composite biological demulsifier has a good demulsification effect on the oilfield production fluid with a pH of 7-10, and reduces the oil content in the oilfield production fluid by more than 90%, which shows that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com