Device for characterizing the particle size distribution of powders and its uses

A characterization and powder technology, applied in the direction of measuring devices, particle size analysis, chemical instruments and methods, etc., can solve the problems of changing the pitch of the helix, destroying the spring, and no longer ensuring the integrity of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

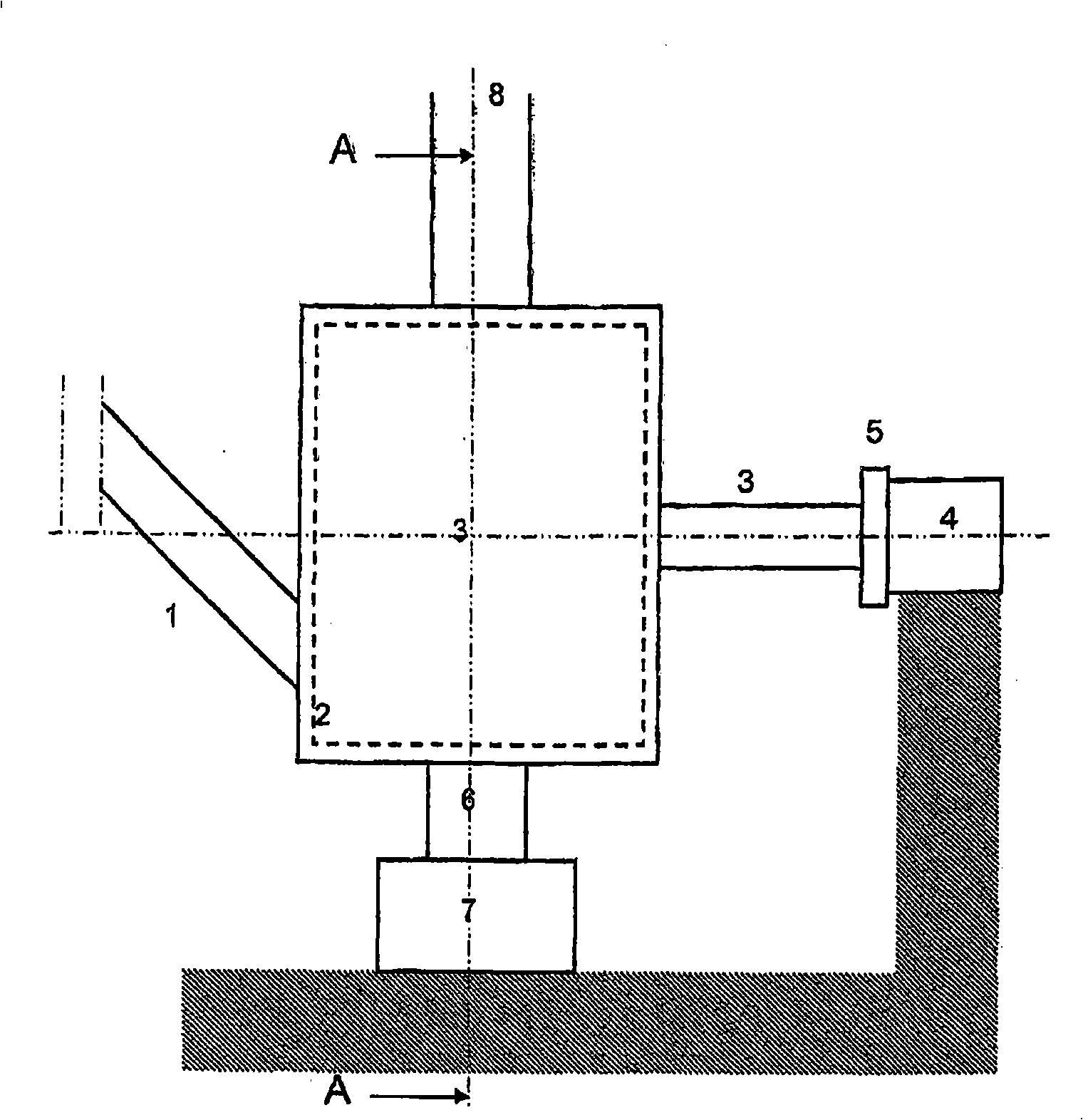

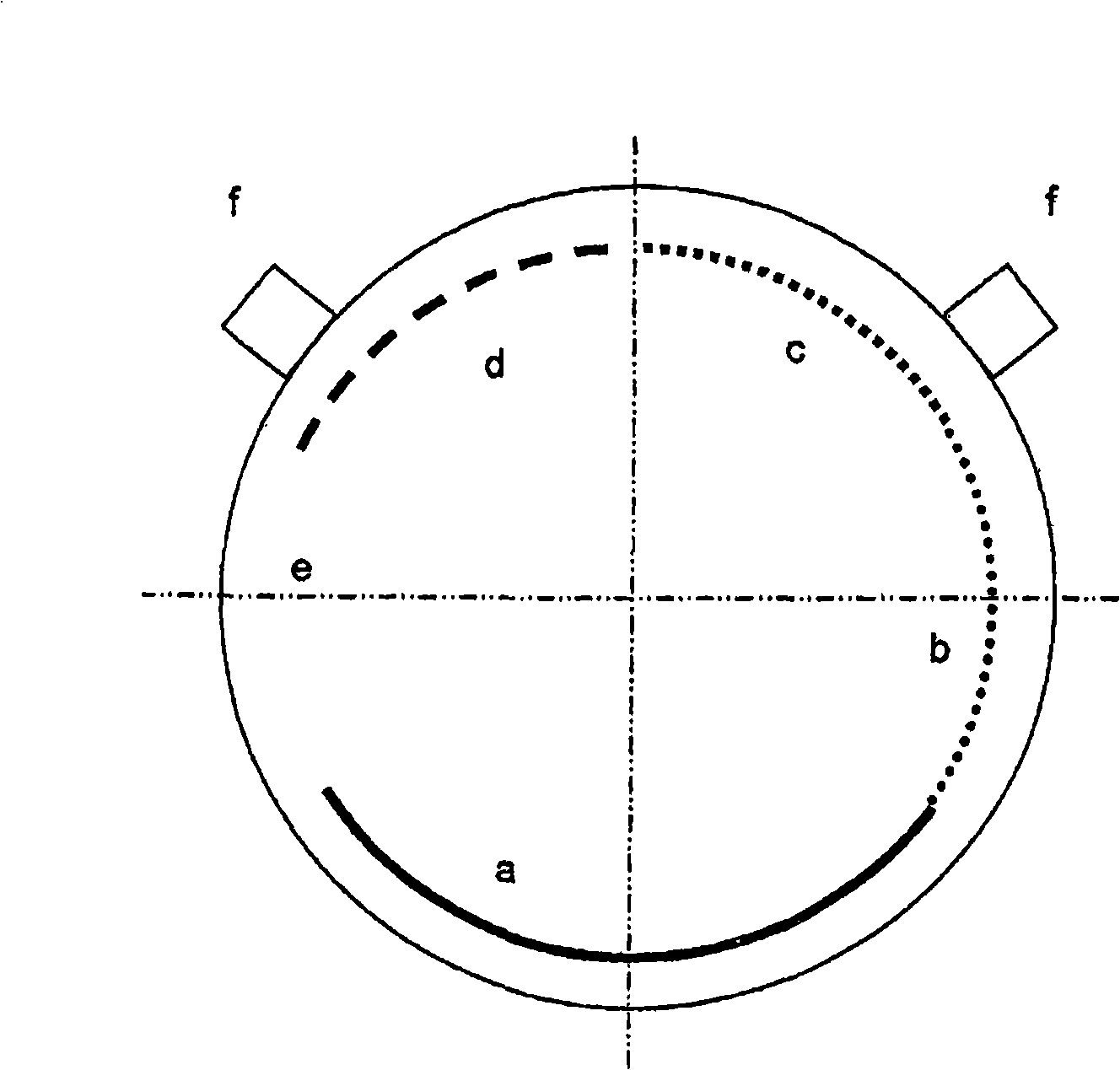

Method used

Image

Examples

example 1

[0102] This example shows the use of the present invention to determine OMYA TM The company produces in the Salses (France) factory and uses Durcal TM The particle size characteristics of the calcium carbonate powder sold under the name 130.

[0103] To this end, four filter screens are installed in the device of the present invention, with meshes equal to 100 μm, 250 μm, 355 μm, and 500 μm to meet the needs of analyzing the above-mentioned powder products (customer's quality indicators, etc.). The time for the powder to pass through each sieve is equal to 06:00 minutes, 07:30 minutes, 04:00 minutes, 00:30 minutes, and finally 00:25 minutes at the release position of the largest-scale particles.

[0104] The corresponding results, expressed as the percentage of particles (not acceptable) with a diameter larger than each screen mesh, are shown in Table 1.

[0105] Not accept 100μm (%)

Not accept 250μm (%)

Not accept 355μm (%)

Not accept 500μm (%)

82.09

30.55

0.55

0

78.76

29....

example 2

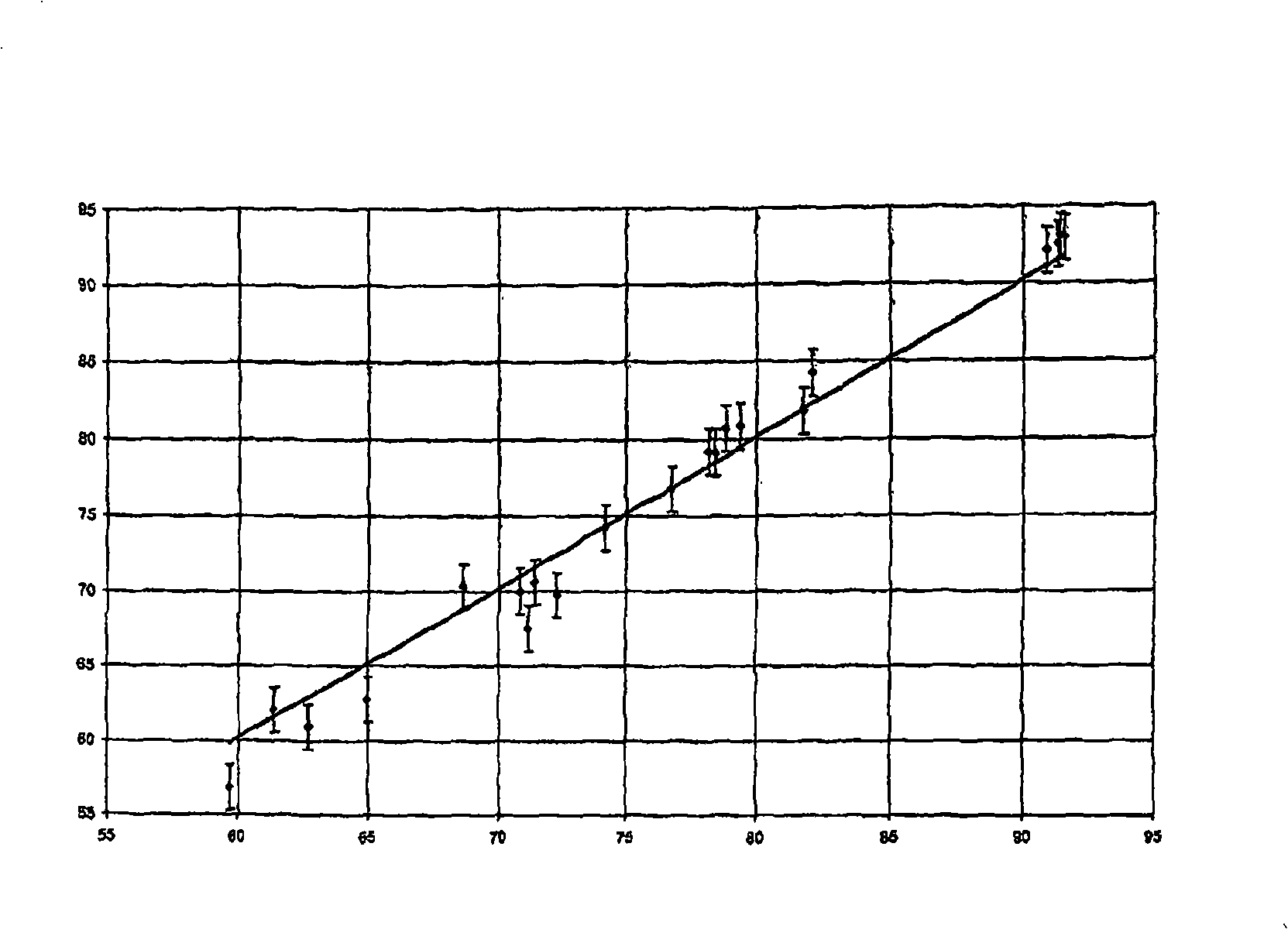

[0109] The purpose of this example is to show the reliability of the device of the invention for the correlation between the measurement of the same sample by the device of the invention and the laboratory manual measurement.

[0110] This example uses OMYA TM The company produces in the Salses (France) factory and uses Durcal TM Calcium carbonate powder sold under the name of 130.

[0111] Different samples of the powder have been analyzed under the same conditions as described in Example 1 with the device according to the invention.

[0112] At the same time, these samples were manually sieved through a 100μm filter and another 250μm filter.

[0113] At the end of this article image 3 , 4 Represents the relationship between the non-acceptance (vertical axis or y-axis) based on laboratory manual measurement and the non-acceptance of measurement according to the present invention (abscissa axis or x-axis):

[0114] -At 100μm( image 3 Represents a linear regression line, its equation i...

example 3

[0118] This example shows the use of the present invention for Cristal Union TM The crystalline white sugar powder produced by the company in the Corbeilles (France) plant and sold in the form of powdered sugar is characterized by particle size.

[0119] To this end, 5 filter screens are installed in the device of the present invention, with meshes equal to 125 μm, 250 μm, 500 μm, 630 μm, and 800 μm, which meet the needs of analyzing the above-mentioned powders (customer's quality indicators, etc.). The time for the powder to pass through each sieve is equal to 06:30 minutes, 06:00 minutes, 06:00 minutes, 05:00 minutes, and 03:30 minutes, and finally the release position of the largest-scale particles is 02:30 minutes.

[0120] The corresponding results, expressed as the percentage of particles (not acceptable) with a diameter larger than each screen mesh, are shown in Table 2.

[0121] Not accept 125μm (%)

Not accept 250μm (%)

Not accept 500μm (%)

Not accept 630μm (%)

800μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com