Engine cooling structure

A technology of cooling structure and engine, applied in the direction of engine cooling, engine components, machine/engine, etc., can solve the problems of no disclosure of the radiator hose installation structure and difficult transmission of vibration in the intake passage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

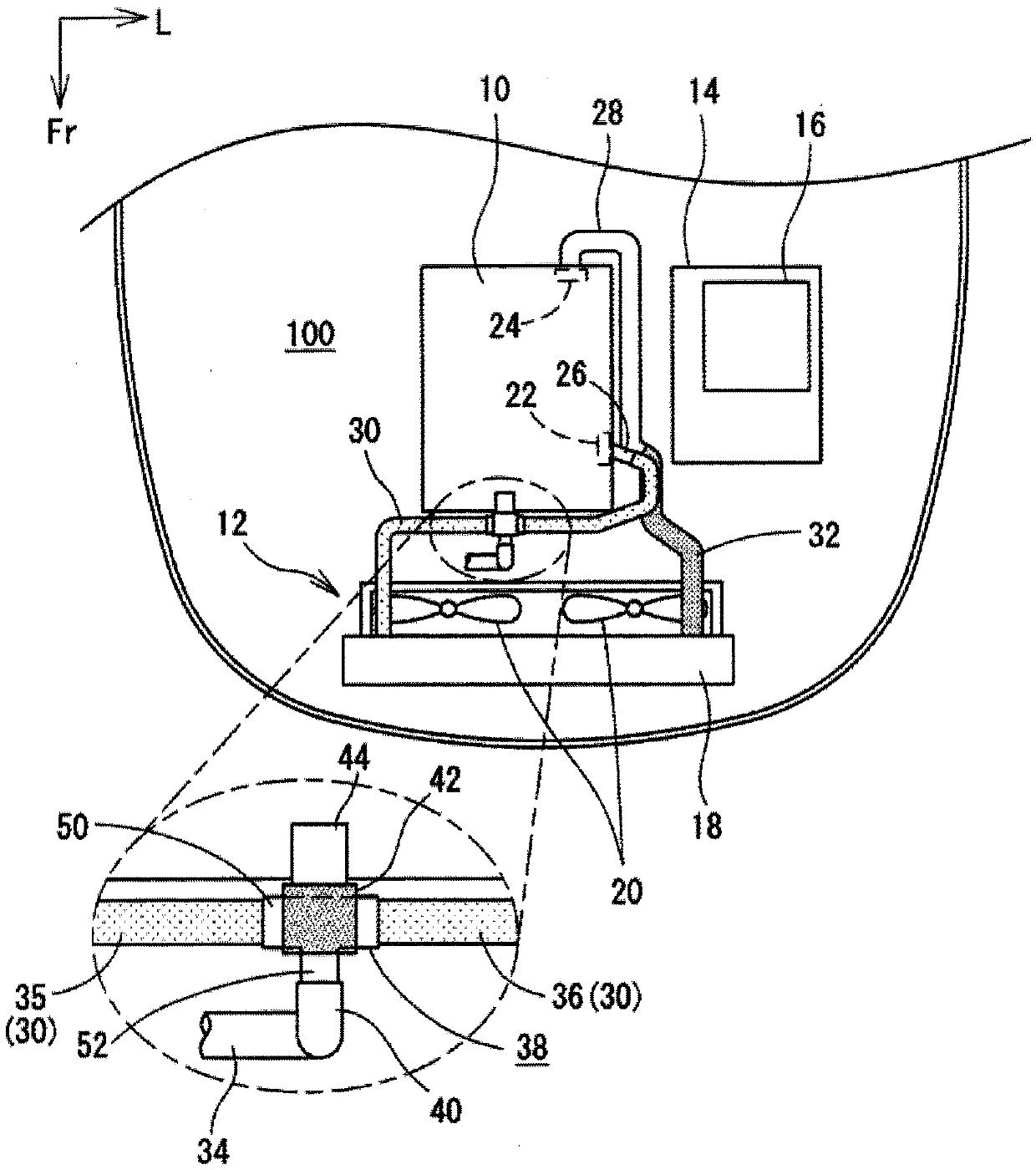

[0034] Hereinafter, the cooling structure of the engine 10 will be described with reference to the drawings. figure 1 It is a schematic plan view of the front part of a vehicle. It should be noted that, in figure 1 In the drawing, the outlet pipe 28 is shown thicker than the inlet pipe 26 in order to easily distinguish the inlet pipe 26 and the outlet pipe 28 , but actually the two pipes 26 and 28 have the same diameter. Likewise, the outlet hose 32 is shown thicker than the inlet hose 30, but in reality both hoses 30, 32 are of the same diameter. Moreover, in figure 1 , figure 2 In , light ink is applied to the inlet hose 30 and thick ink is applied to the outlet hose 32 .

[0035] This vehicle is a hybrid vehicle having an engine 10 and an electric motor as power sources for driving the vehicle. However, the technology disclosed in this specification is not limited to a hybrid vehicle, and may be applied to a vehicle having only engine 10 as a power source.

[0036] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com