Piston pump, in particular fuel pump, having roller tappet

A piston pump and high-pressure fuel pump technology, applied in fuel injection pumps, fuel injection devices, pumps, etc., can solve problems such as strong wear and tear, and achieve the effect of not easy to wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

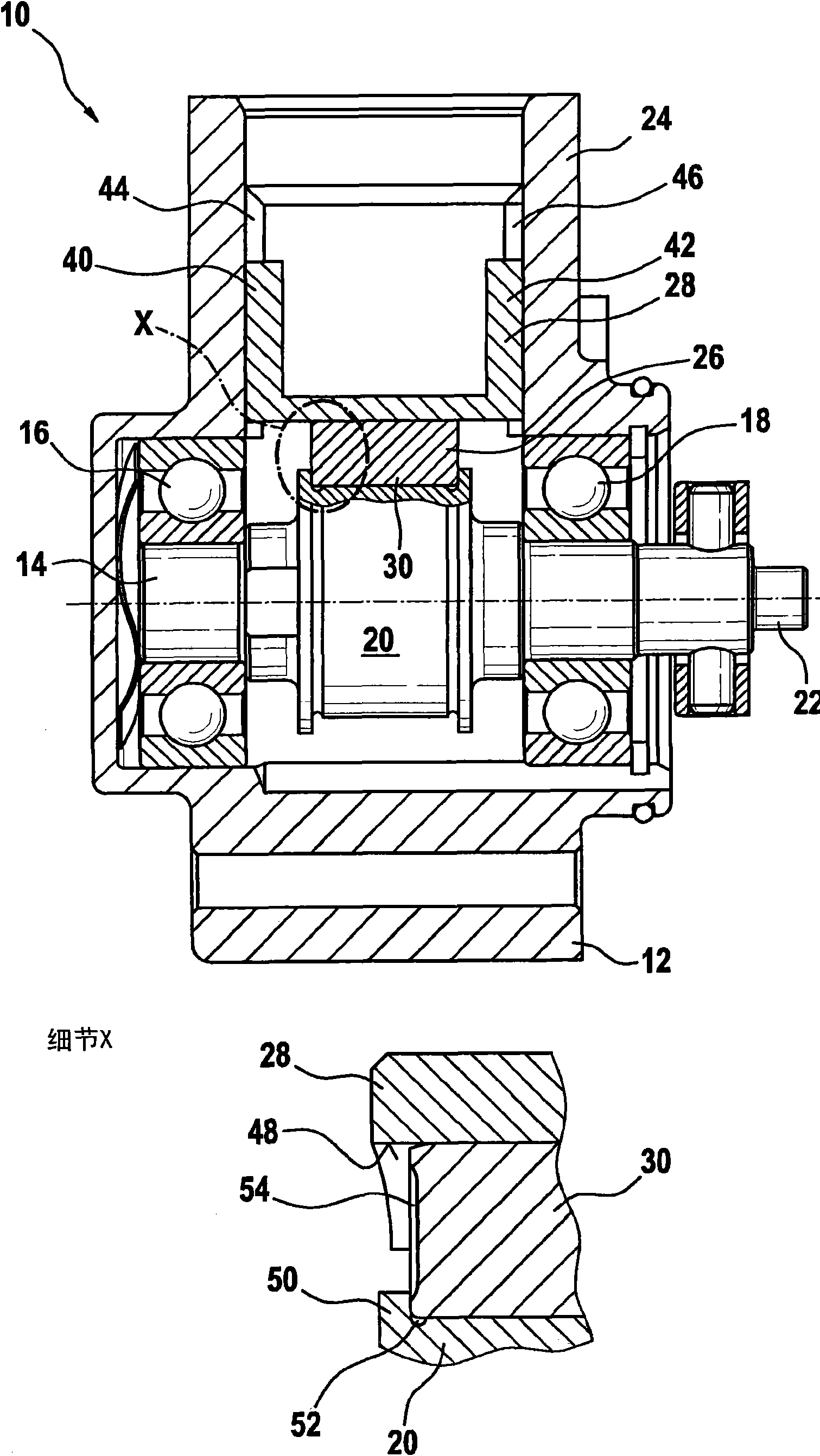

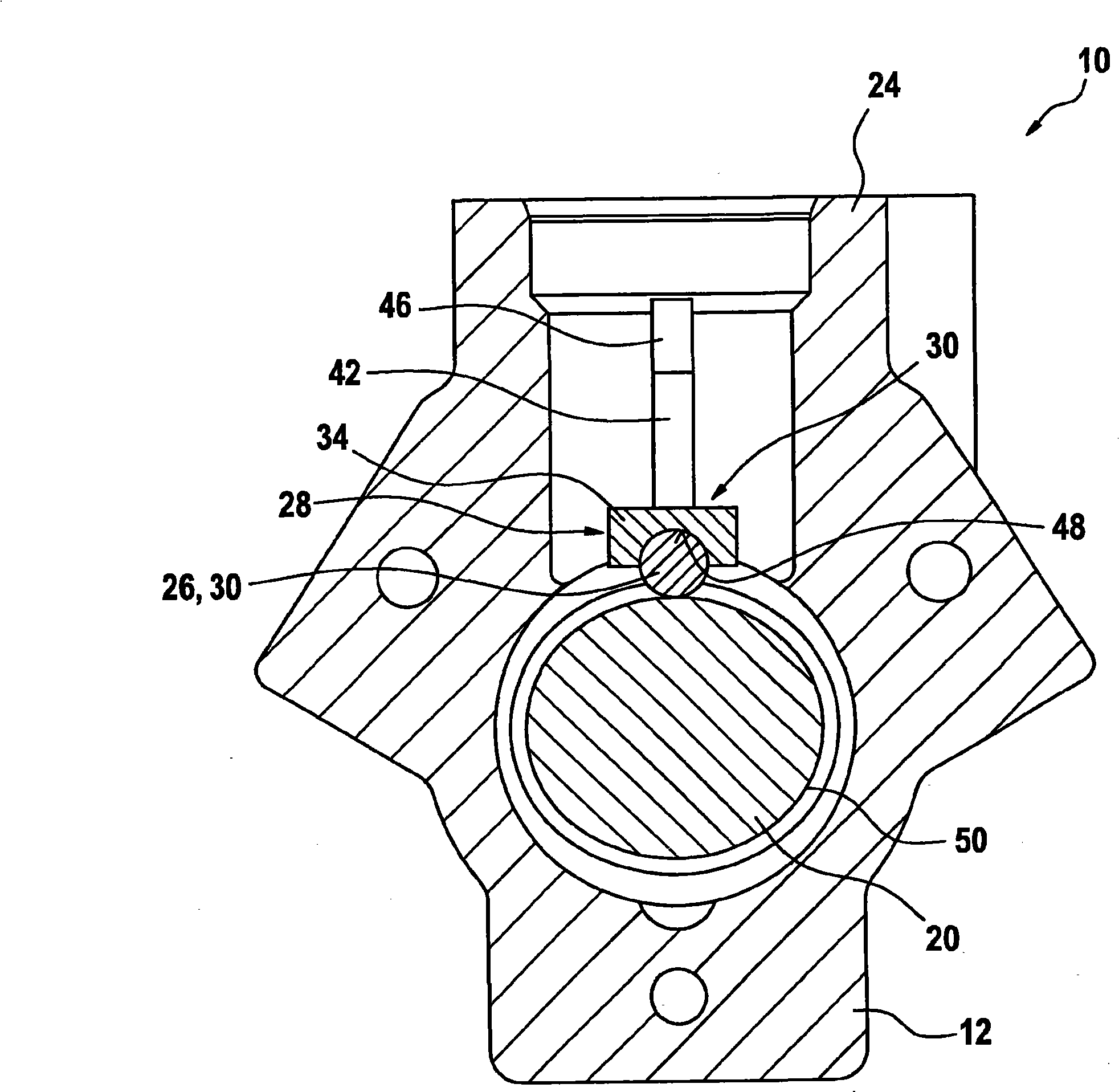

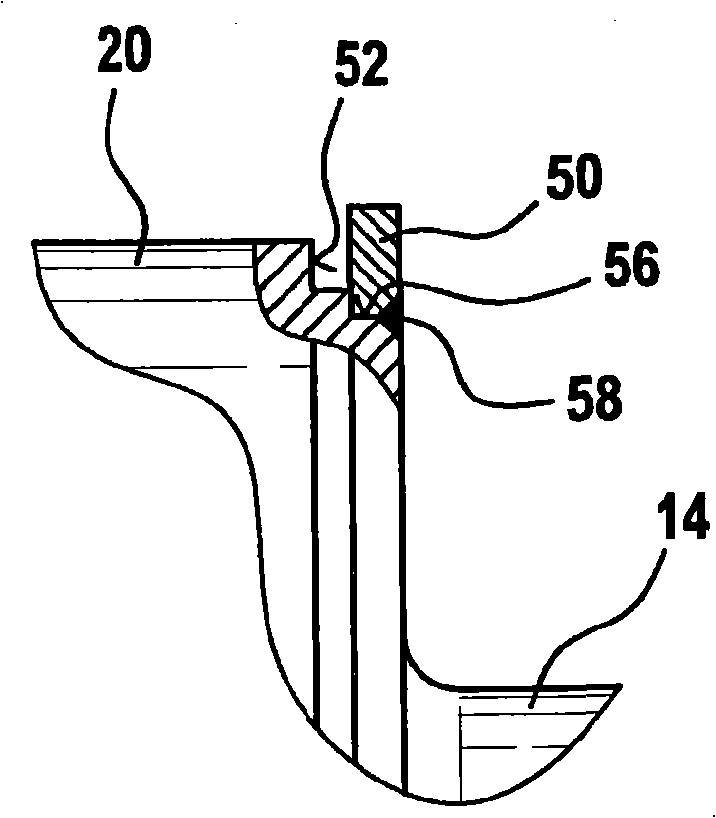

[0021] figure 1 The piston pump in is indicated generally by reference numeral 10 . It comprises a housing 12 in which a drive shaft 14 is supported via two bearings 16 and 18 . especially by figure 2 It can be seen that the drive shaft 14 comprises, between the two bearings 16 and 18 , a cam section 20 with an oblong cross-section.

[0022] figure 1 and 2 The piston pump 10 shown in is used as a high-pressure fuel pump for internal combustion engines in automobiles. With the high pressure fuel pump, fuel is compressed to very high pressure and delivered to a fuel rail (not shown). In this case, the drive shaft 14 of the piston pump 10 is directly driven by the internal combustion engine. The drive shaft 14 is therefore provided with a corresponding coupling section 22 arranged outside the housing 2 .

[0023] The piston pump 10 is a single-cylinder radial piston pump. For the sake of clarity, however, neither the piston nor the delivery chamber delimited by it and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com