Air conditioning controller special for curing tobacco and control method thereof

An air-conditioning controller and control method technology, which is applied in the program control of sequence/logic controller, electrical program control, heating and ventilation control system, etc., can solve the problem of low degree of automation, inconsistency of dry bulb temperature and wet bulb temperature, The lack of air convection and other problems can achieve the effect of improving the degree of automation and control accuracy, reducing the difficulty and intensity of work, and reducing the intensity of baking work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

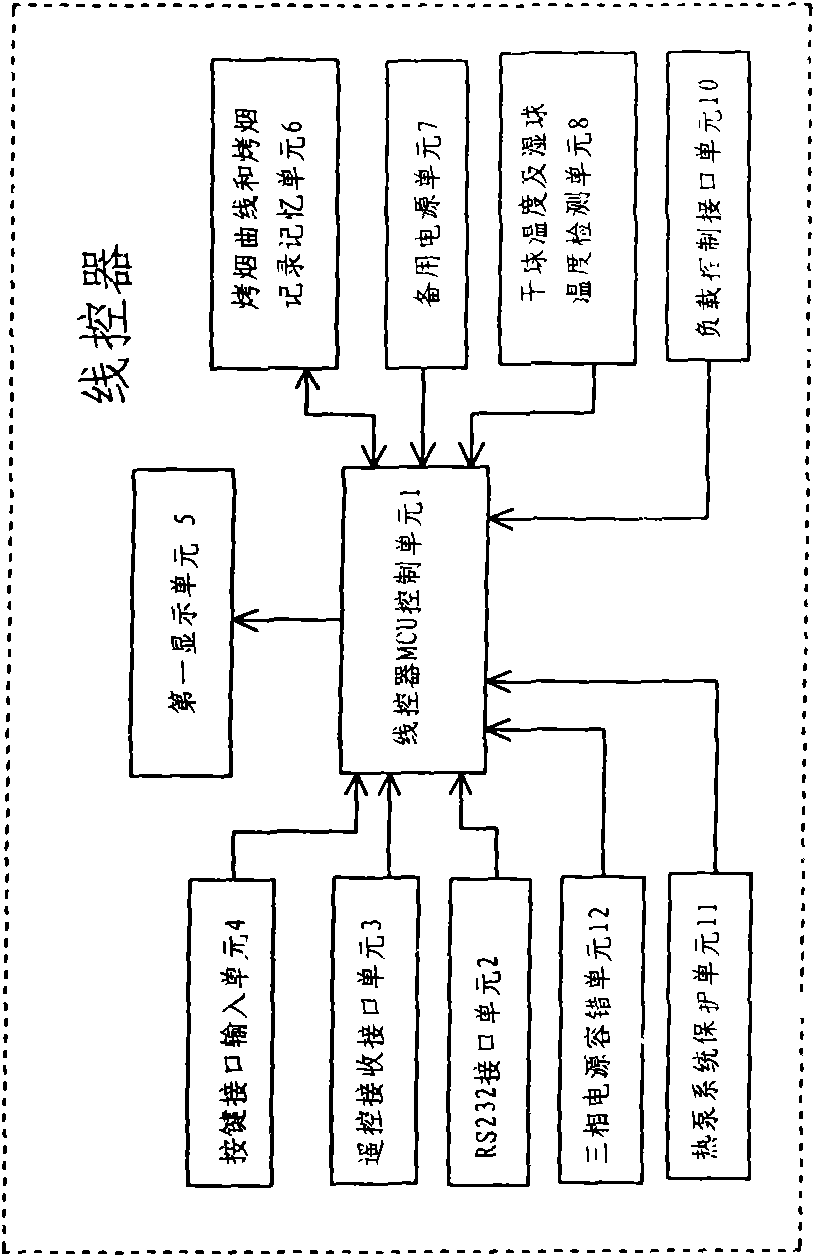

[0043] see figure 1 The air conditioner controller dedicated to flue-cured tobacco includes a wire controller and a load controller. The wire controller includes a connected input unit and a wire controller MCU control unit 1. The input unit is an RS232 interface unit 2, a remote control receiving interface unit 3 and The key interface input unit 4, the wire controller MCU control unit 1 receives parameter setting and control instructions through the input unit. The load controller includes a load controller MCU control unit 13, and the wire controller MCU control unit 1 is respectively connected with the first display unit 5, the flue-cured tobacco curve and the flue-cured tobacco record memory unit 6, the backup power supply unit 7, and the dry bulb temperature and wet bulb temperature detection unit 8, the load controller MCU control unit 13 is respectively connected with the second display unit 9, the load control interface unit 10, the heat pump system protection unit 11 ...

no. 2 example

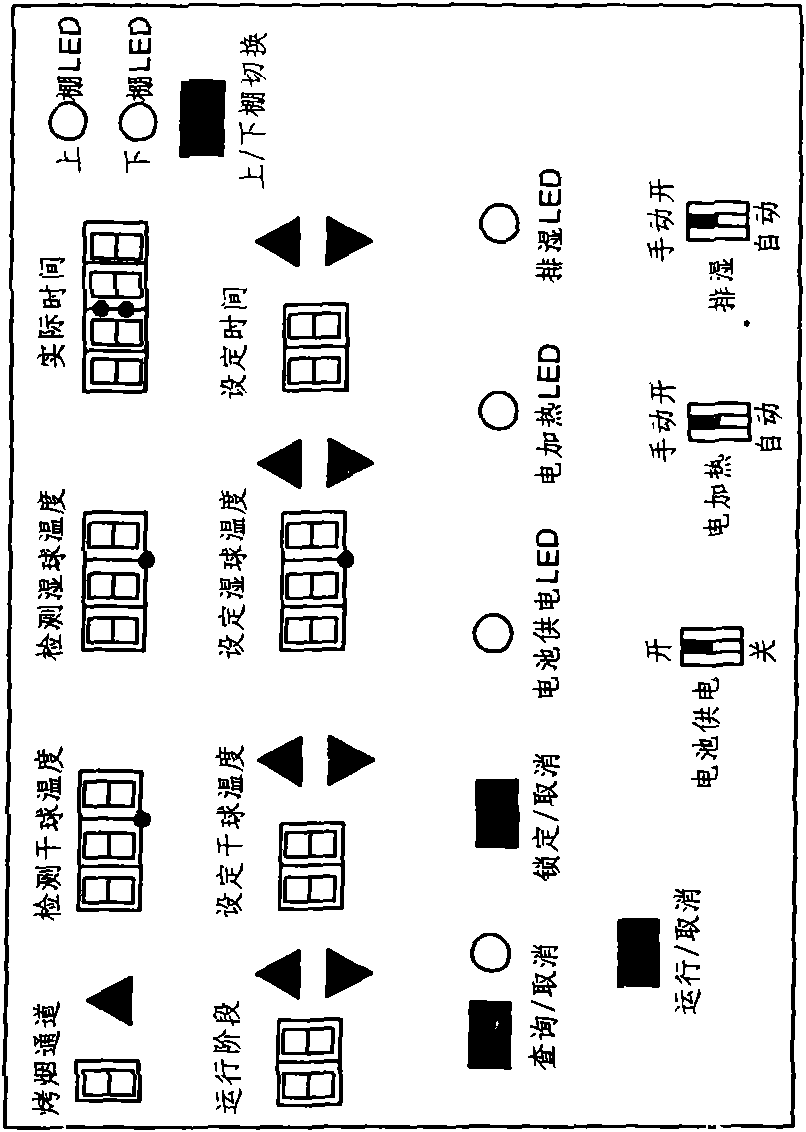

[0085] see image 3 , the air conditioner controller dedicated to flue-cured tobacco, including a wire controller, the wire controller includes a connected input unit and a wire controller MCU control unit 1, the input unit is an RS232 interface unit 2, a remote control receiving interface unit 3 and a key interface input unit 4. Wire controller MCU control unit 1 is connected with the first display unit 5, flue-cured tobacco curve and flue-cured tobacco record memory unit 6, backup power supply unit 7, dry bulb temperature and wet bulb temperature detection unit 8, load control interface unit 10, heat pump system The protection unit 11 and the three-phase power supply fault-tolerant unit 12 are connected; the wire controller MCU control unit 1 receives control instructions from the input unit to control the working status of the heat pump, electric heater and dehumidifier.

[0086] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com