Radial power rotor engine

A technology of rotary engine and engine casing, used in rotary piston engine, rotary or oscillating piston engine, machine/engine, etc., can solve the problem of high fuel consumption rate and rotational speed, high difficulty in manufacturing turbine blades, and large torque alternation, etc. problem, to achieve the effect of large fuel explosive force, simple structure, and improved low-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

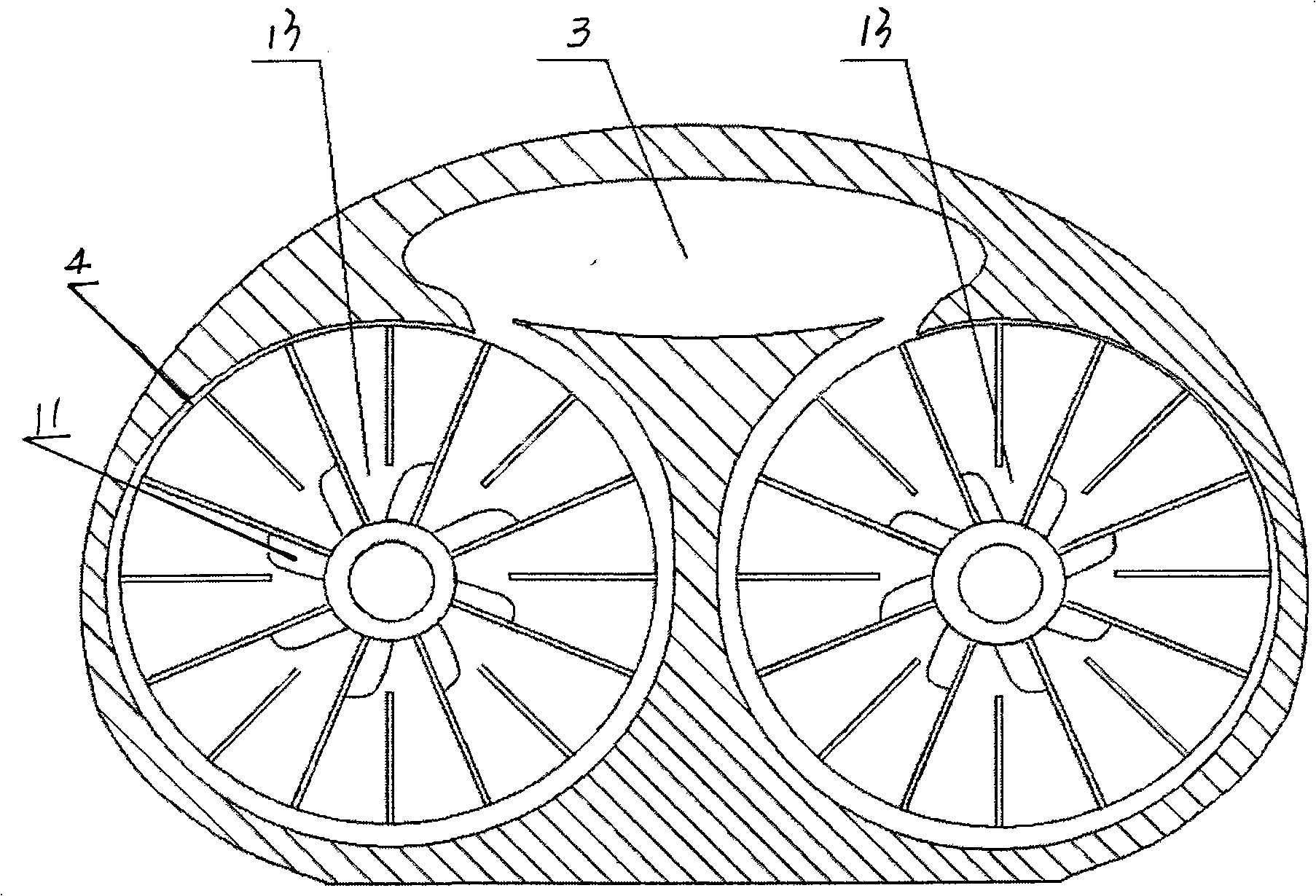

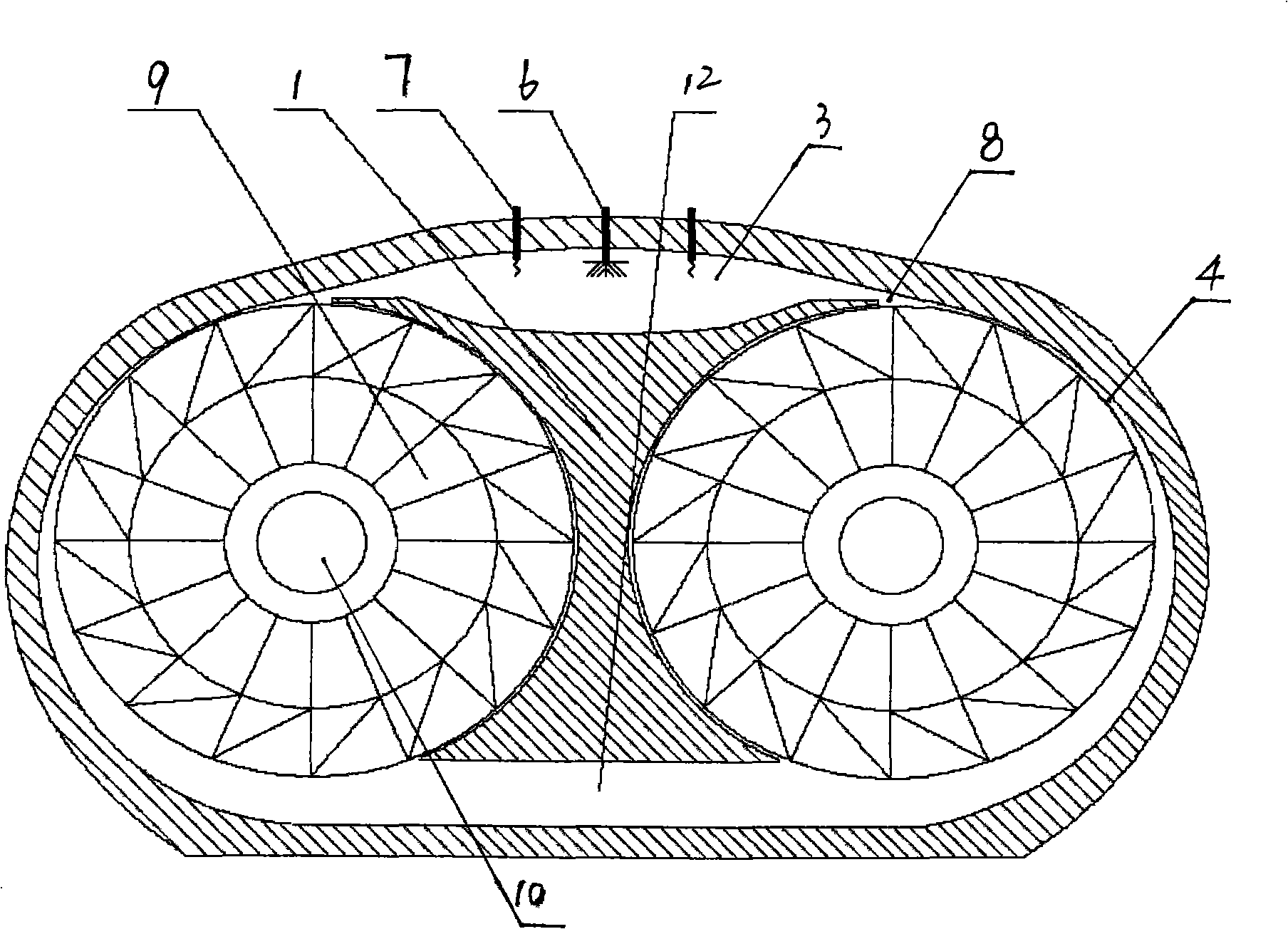

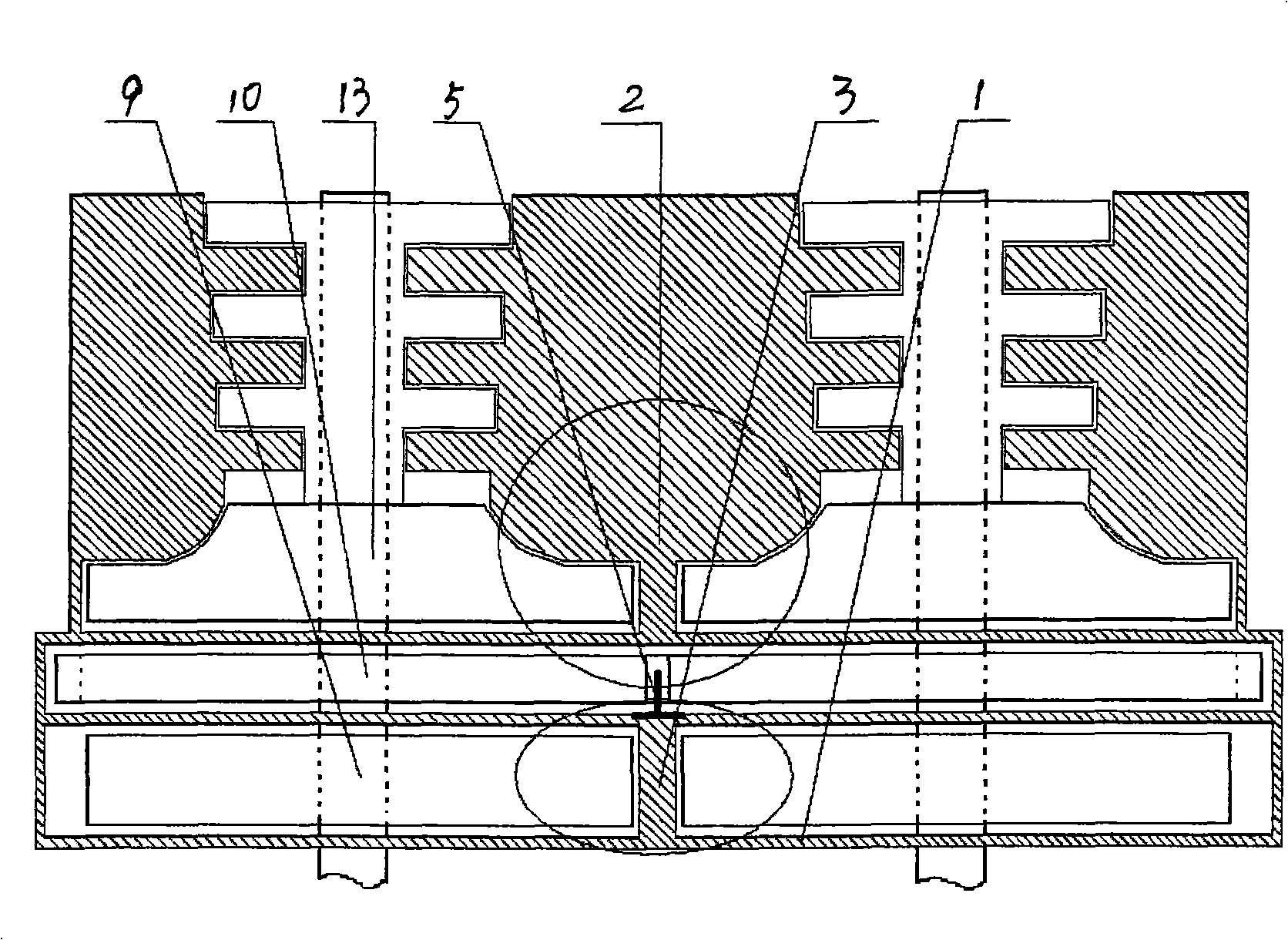

[0019] like Figure 1-3 As shown, a compressed air buffer chamber 2, a combustion chamber 3 and a rotor chamber 4 are formed in the engine casing 1, and the air outlet of the air compressor 13 communicates with the combustion chamber 3 through the compressed air buffer chamber 2 and the one-way valve 5, and the combustion chamber 3 Connect the fuel injection device 6 and the timing ignition device 7, the gas injection port 8 of the combustion chamber 3 communicates with the rotor chamber 4, the direction of the gas injection port 8 of the combustion chamber 3 is level with the inner diameter and outer edge of the rotor chamber 4, and the rotor 9 is installed in the rotor chamber 4. 9 consists of a rotor shaft 10 and rotor blades, the rotor blades 11 are concentrically distributed on the rotor shaft 10, the rotor shaft 10 is installed on the bearing of the engine casing 1, and the rotor shaft 10 is connected to the air compressor 13.

[0020] In the radial power rotary engine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com