Tape picking and laying device of tighter

A belt retracting and tightening technology, which is applied in transportation and packaging, vehicles used for freight, and parts of strapping machinery, etc., can solve the problems of low degree of automation, increased difficulty, and difficult control of use, etc., to achieve improved Safety and convenience, improved use stability, flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

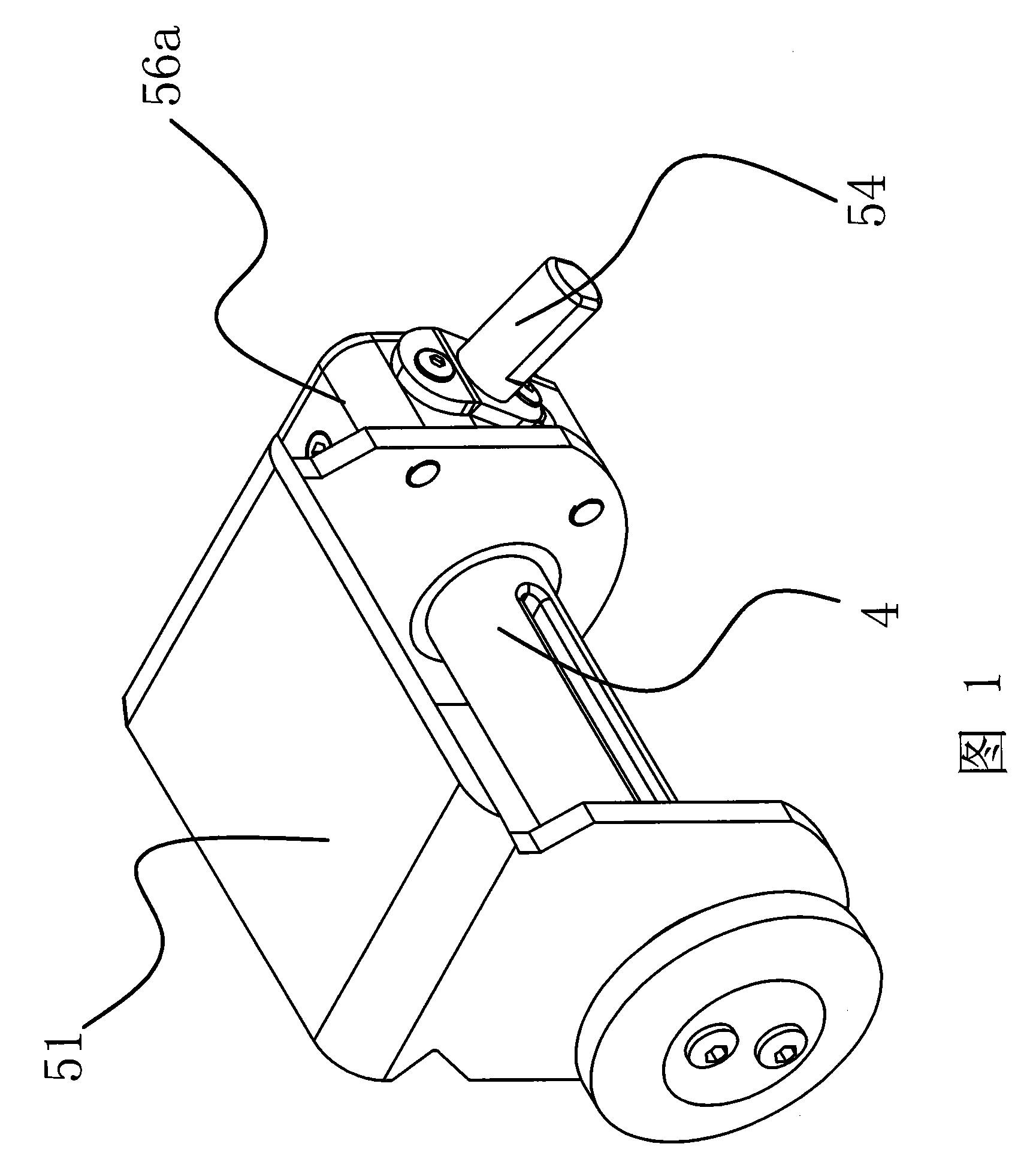

[0032] As shown in FIG. 1 , the tightener has a bracket 51 on which a belt shaft 4 is connected, and one end of the belt shaft 4 protrudes from the bracket 51 and is connected with a belt retracting device.

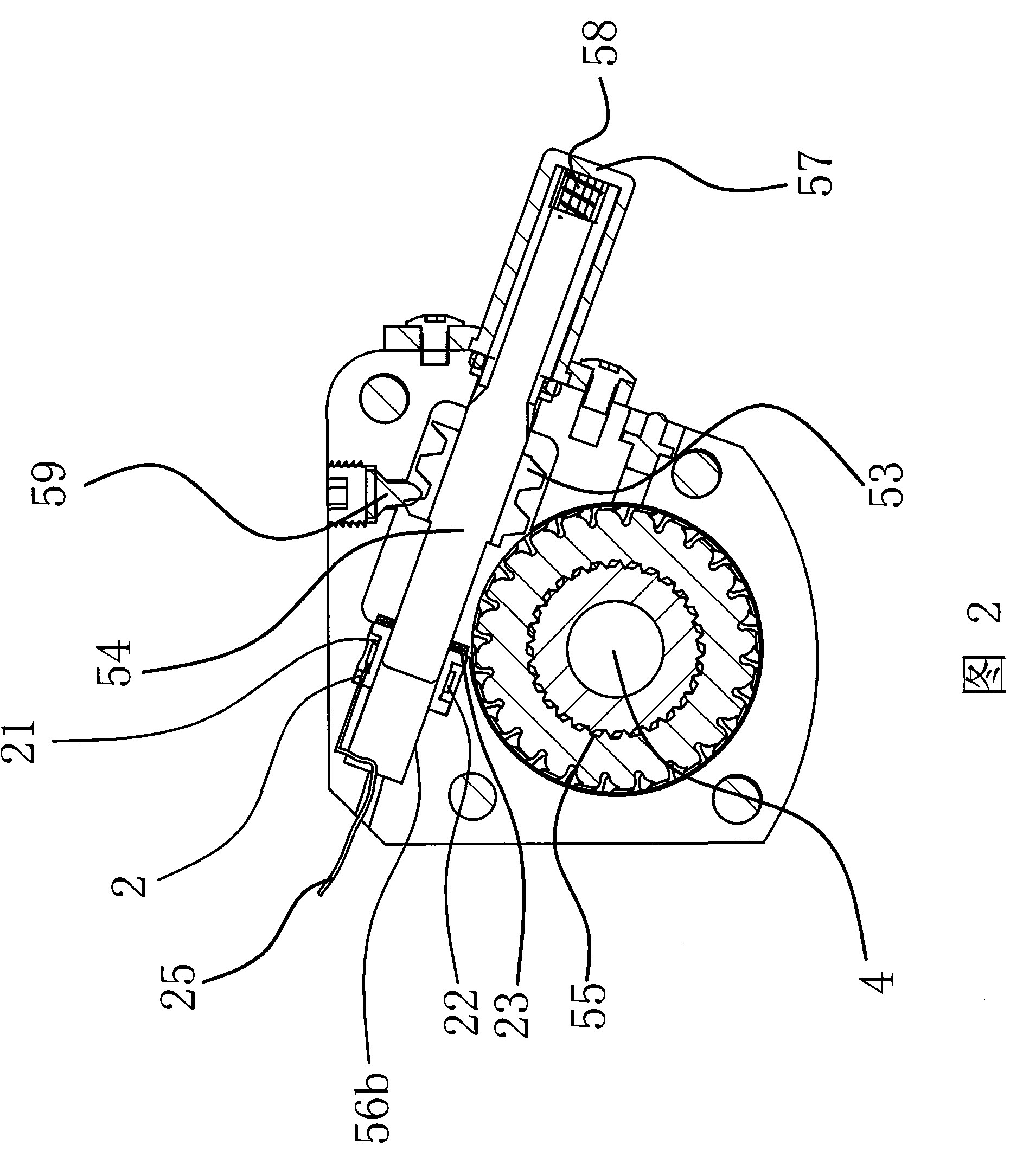

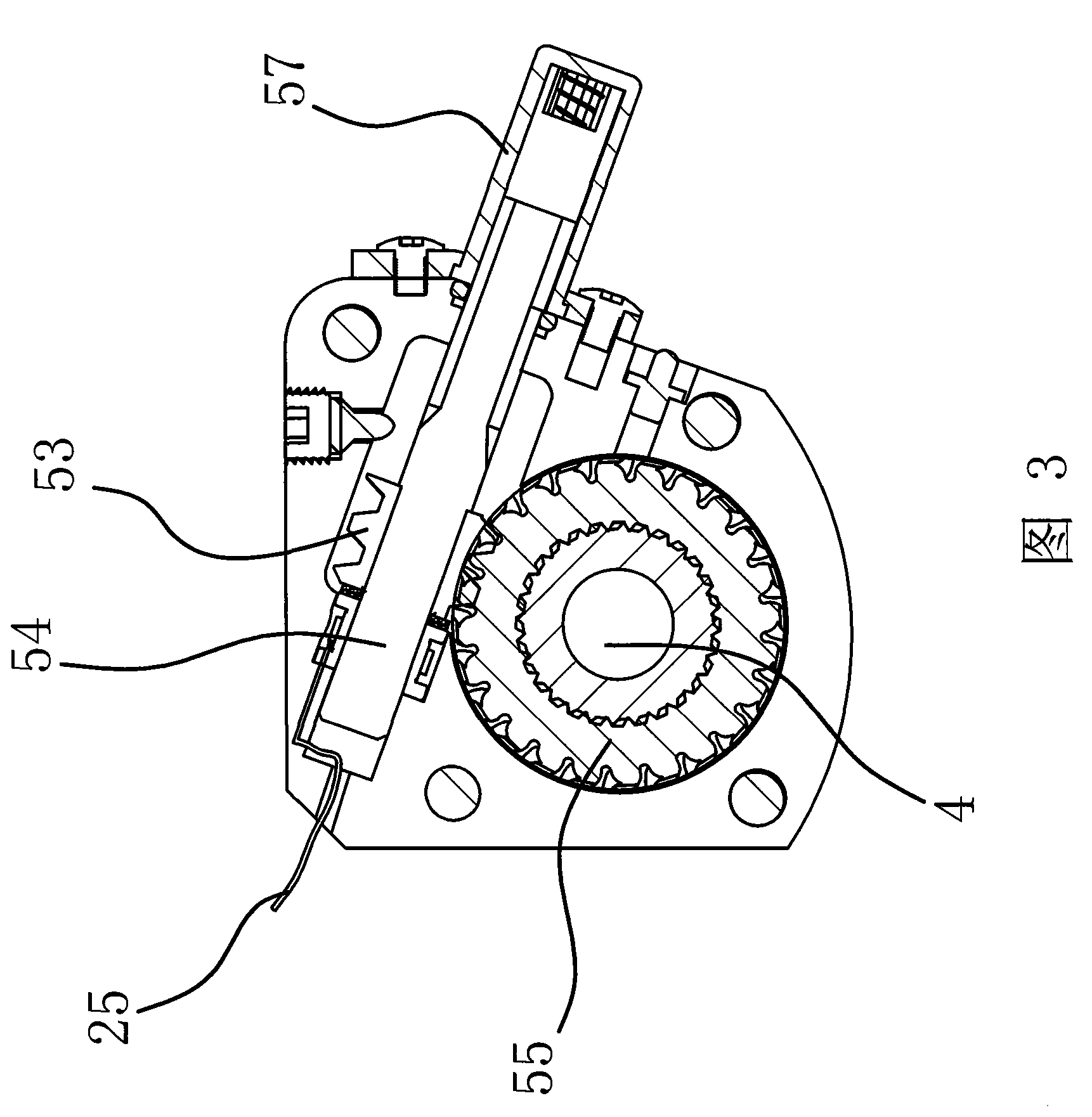

[0033] As shown in Fig. 2 and Fig. 3, this tightener belt retracting device comprises parts such as housing 56a, worm screw 53, worm shaft 54, worm wheel 55, sensor 2, positioner 59, rotating sleeve 57, spring 58.

[0034] A casing 56a with a cavity inside is fixedly connected to the side of the bracket 51, and the worm 53, the worm shaft 54 and the worm wheel 55 are arranged in the casing 56a. The worm 53 is sleeved on the worm shaft 54 and the two are fixedly connected together. Of course, the worm 53 and the worm shaft 54 here can also adopt an integrated structure. The worm wheel 55 is fixedly connected to the protruding end of the belt shaft 4 , and the worm shaft 54 is arranged on the side of the worm wheel 55 and can move in the casing 56 a along its axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com