Numeric control reciprocating drive unit of honing machine spindle

A technology of reciprocating drive device and honing machine, which is applied in the direction of grinding drive device, honing machine tool, grinding machine tool parts, etc. The effect of commutation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

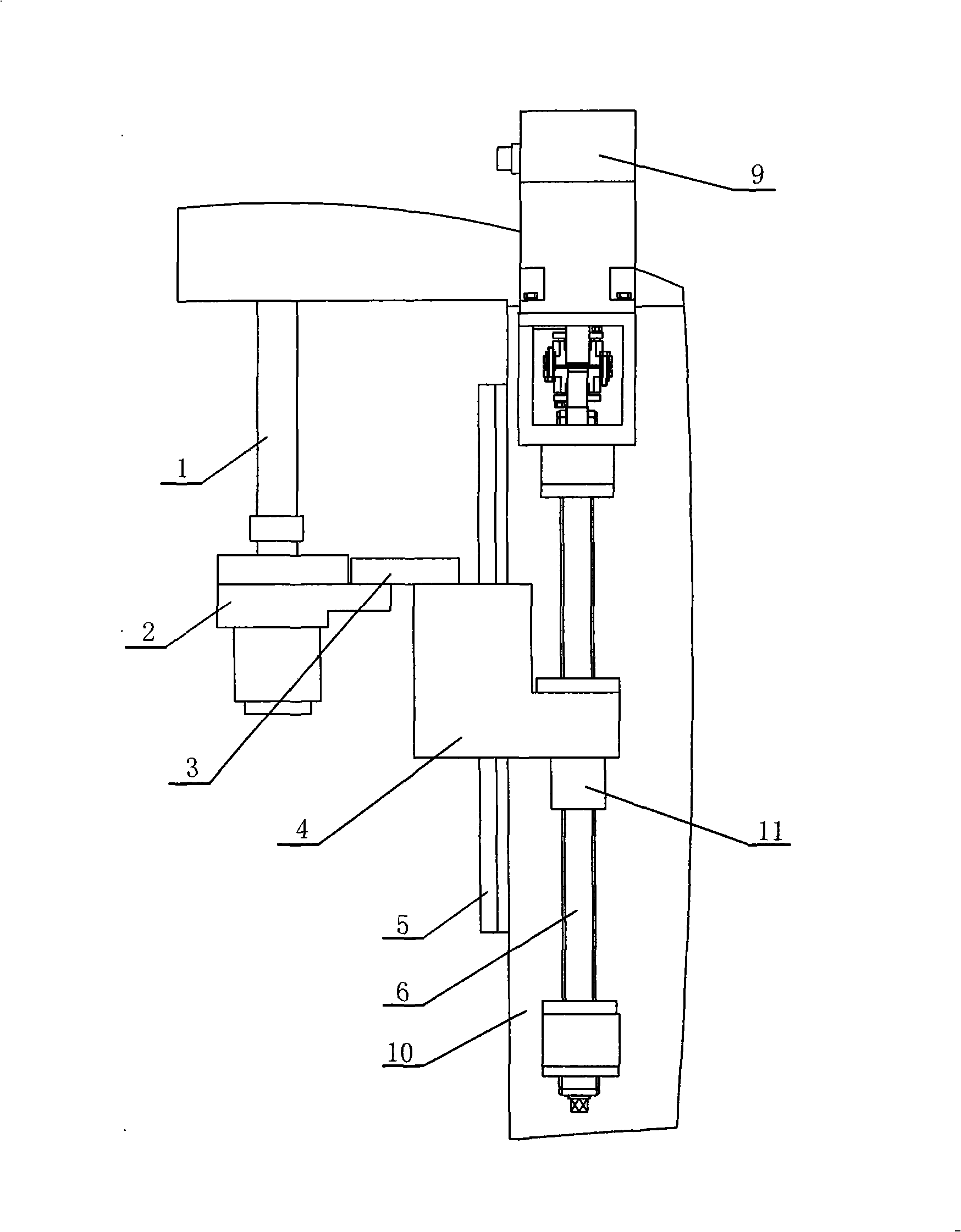

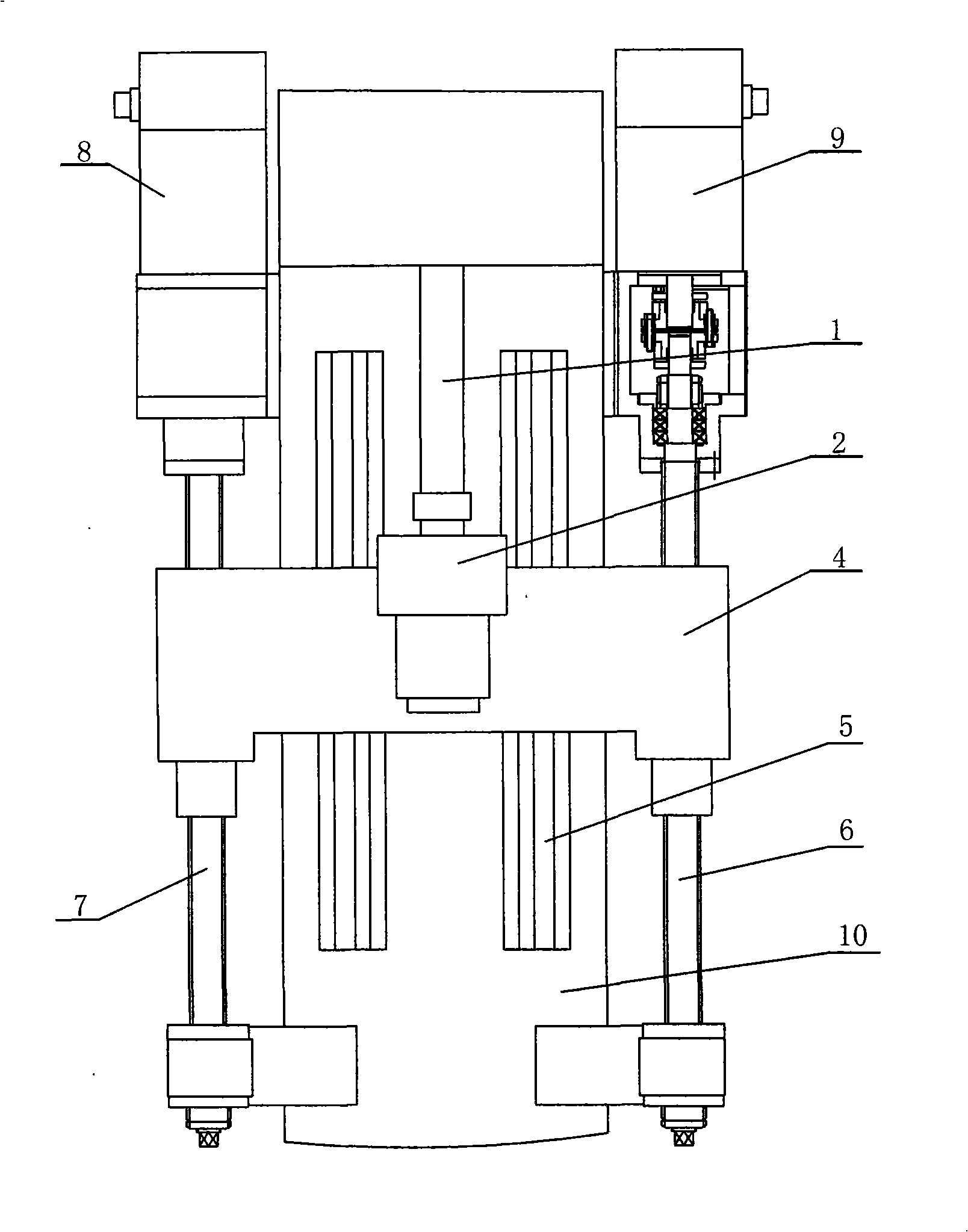

[0013] Such as figure 1 , 2 As shown, two servo motors 8, 9 are installed on the upper end of the bed 10, and the two servo motors are distributed on both sides of the main shaft 1, and the upper ends of the left and right lead screws 6, 7 are respectively connected to the two servo motors through couplings. The lower ends of the left and right lead screws are positioned through the bearing seats fixed on the bed, and the nuts 11 matched with the lead screws are fixedly installed on the horizontal slide 4, and the horizontal slide is movably installed on the bed through the vertical guide rail 5 on the bed , The horizontal sliding seat is connected with the spindle feed box 2 through the connecting plate 3 . In order to increase the guide of the lead screw, the pitch of the lead screw is 20mm. When the two servo motors rotate positively and negatively according to the set program, the horizontal sliding seat 4 is driven to move along the vertical guide rail 5 on the bed thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com