Jet engine nacelle for an aircraft and aircraft comprising such a nacelle

A jet engine and nacelle technology, applied in the direction of machines/engines, air transport, jet propulsion devices, etc., can solve the problems of increasing the complexity and quality of jet nacelles, harmful aerodynamic performance of propulsion devices, etc. The effect of small sound emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

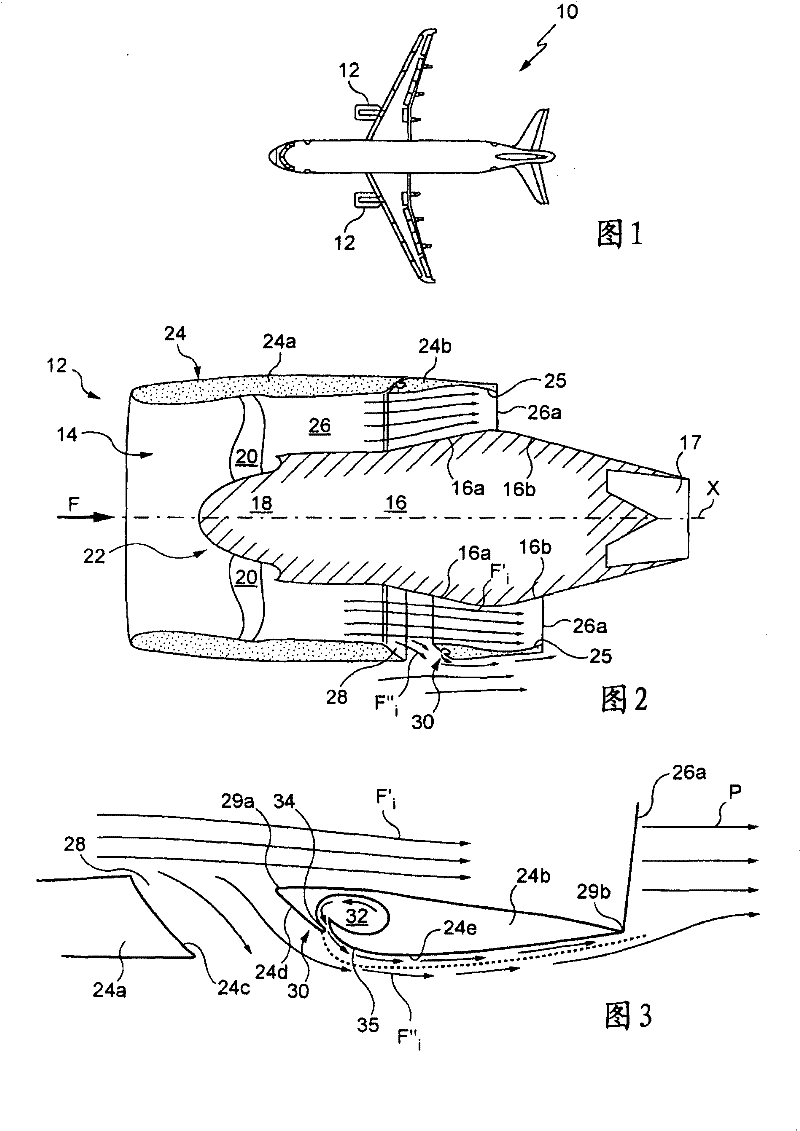

[0043] Such as figure 1 As shown, a commercial aircraft (airline) 10 has a plurality of jet engine nacelles 12 secured to the underside of the aircraft's main wings.

[0044] For example, aircraft 10 is provided with two jet nacelles, each nacelle attached to one of the wings, however, depending on the type of aircraft, multiple nacelles may be attached to the same wing.

[0045] In addition, it may be considered to fix the jet engine nacelle directly on the fuselage, or on both sides of the fuselage, or on the rear upper part of the fuselage.

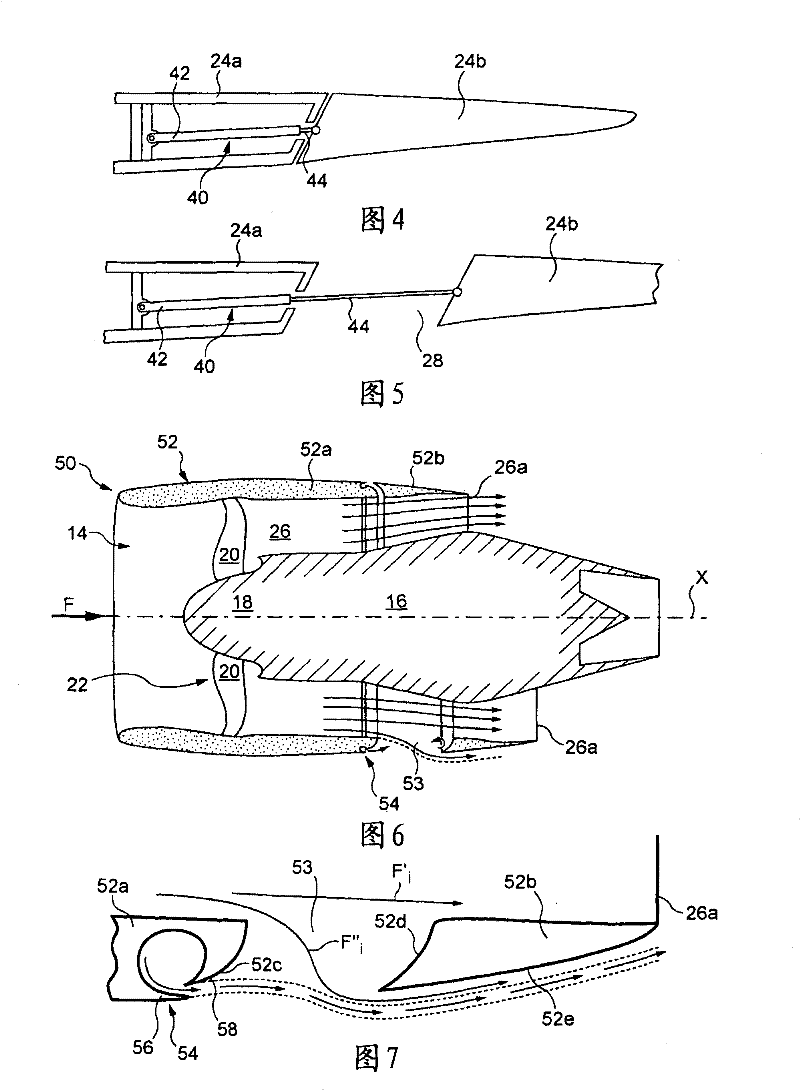

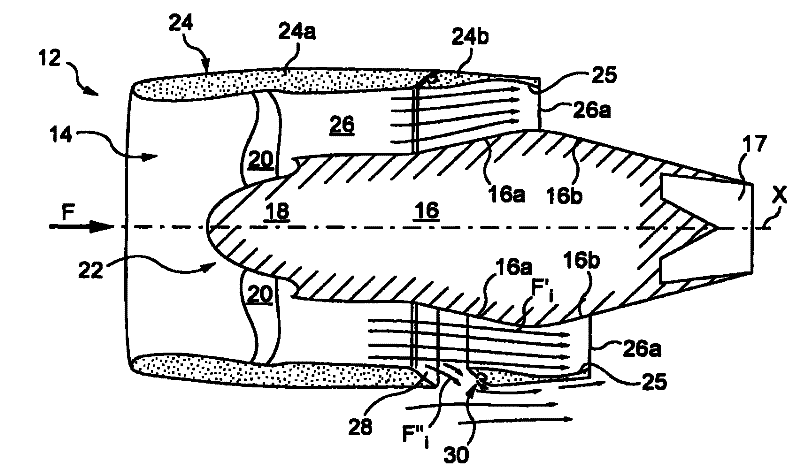

[0046] FIG. 2 schematically shows one of the nacelles 12 according to the invention in longitudinal section.

[0047] A jet engine 14 with longitudinal axis X mounted in the nacelle has a turbine 16 at the inlet, on the upstream side (left in the figure), with a shaft 18 on which is mounted a supercharger 22 of blades 20. The turbines are twin-flow and high bypass ratio turbines (bypass ratio greater than or equal to 5).

[0048] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com