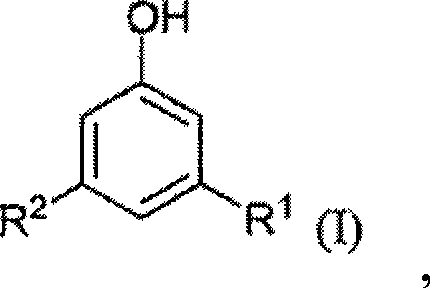

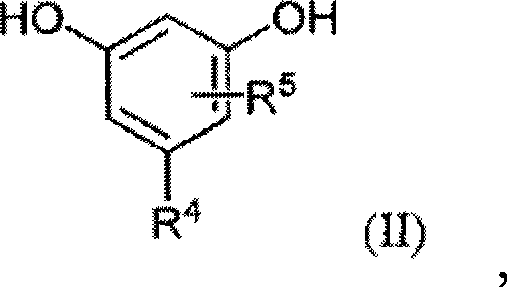

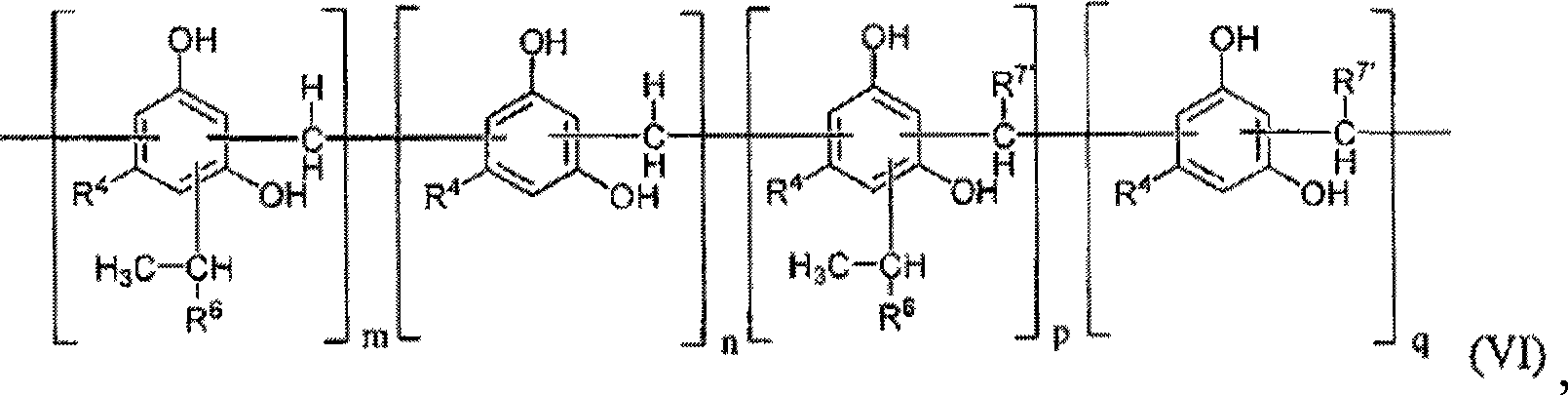

Modified alkylresorcinol resins and applications thereof

A technology of alkyl resorcinol resin, alkyl resorcinol, applied in the application field of rubber composition formulation, can solve problems such as health and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Synthesis of Alkyl Resorcinol-Formaldehyde and Alkyl Resorcinol-Resorcinol-Formaldehyde Resins

[0103] Table 2. Synthesis of Alkyl Resorcinol-Formaldehyde Resins

[0104]

Resin number

1 2 3 4 5 6 7 8 Raw material (mole)

Resorcinol

Resorcinol homopolymer

HONEYOL

Resin properties

Softening point (℃)

Free resorcinol (% by weight)

Free 2-methylresorcinol

(%weight)

Free 5-methylresorcinol

(%weight)

Free 2,5-dimethylm-benzene

Diphenol (% by weight)

0 0 0 0.18 0.36 0.54 1.20 0

0 0 0 0 0 0 0 0.75

1.67 1.67 1.67 1.50 1.30 1.17 0.67 0.88

0.88 0.79 0.84 0.84 0.85 0.86 0.83 1.01

112.9 96.3 103.3 103.1 100.7 98.7 83.6 115.5

0.6 1.1 0.5 2.7 5.0 7.5 17.0 5.6

<0.1 <0.1 0.51 0.38 0.53 0.49 <0.05 <0.05

5.6 7.6 7.2 6.9 6.6 5.7 3.9 1.9

1.6 1.7 1.9 1.6 1.5 1.2 ...

Embodiment 2

[0111] Synthesis of Alkyl Resorcinol-Styrene-Formaldehyde Resin

[0112] Table 3. Synthesis of Alkyl Resorcinol-Styrene-Formaldehyde Resins

[0113]

Resin number

9 10 11 12 13 14 Raw material (mole)

HONEYOL

Resin properties

Softening point (℃)

Free resorcinol (% by weight)

Free 2-methylresorcinol

(%weight)

Free 5-methylresorcinol

(%weight)

Free 2,5-dimethylisophthalic di

Phenol (% by weight)

1.49 1.49 1.49 1.49 1.49 1.49

0.80 0.64 0.64 0.38 0.25 0.50

0.73 0.73 0.73 0.73 0.73 0.73

95.4 100.7 98.0 97.8 99.1 98.7

0.04 0.14 0.05 0.17 0.14 0.03

<0.05 <0.05 <0.01 <0.01 <0.01 <0.01

0.6 ...

Embodiment 3

[0122] Testing of Alkyl Resorcinol-Formaldehyde Resins

[0123] Rubber compounds B and C were prepared using alkylresorcinol-formaldehyde resins 1 and 2, respectively, according to the procedure described above, and the acceptor / donor ratios were as shown in Table 4 below. Use separately Resin B-19-S, VKG SF-281 and VKG AFES were used as methylene acceptors, and rubber compounds A, D and E were similarly prepared as controls. The physical properties of the rubber compounds were evaluated accordingly and the test results are listed in Table 4 below. The data in Table 4 show that Compounds A-E are similar in Mooney viscosity, rheological cure, wire adhesion, dynamic mechanical properties, Shore A hardness values, tensile properties, and Type C die tear properties.

[0124] Table 4.

[0125]

[0126]

[0127] Note: Resin B-19-S was obtained from INDSPEC Chemical Corporation, Pittsburgh, PA. VKG SF-281 and VKG AFES were obtained from VKG Oil AS, Kohtla-Jarve, Estonia....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com