Packaging bag with fastener tape

A packaging bag and buckle technology, which is applied in packaging, transportation and packaging, bags, etc., can solve the problem of not easy to disconnect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0051] First, refer to Figure 1 to Figure 3 The first embodiment of the present invention will be described.

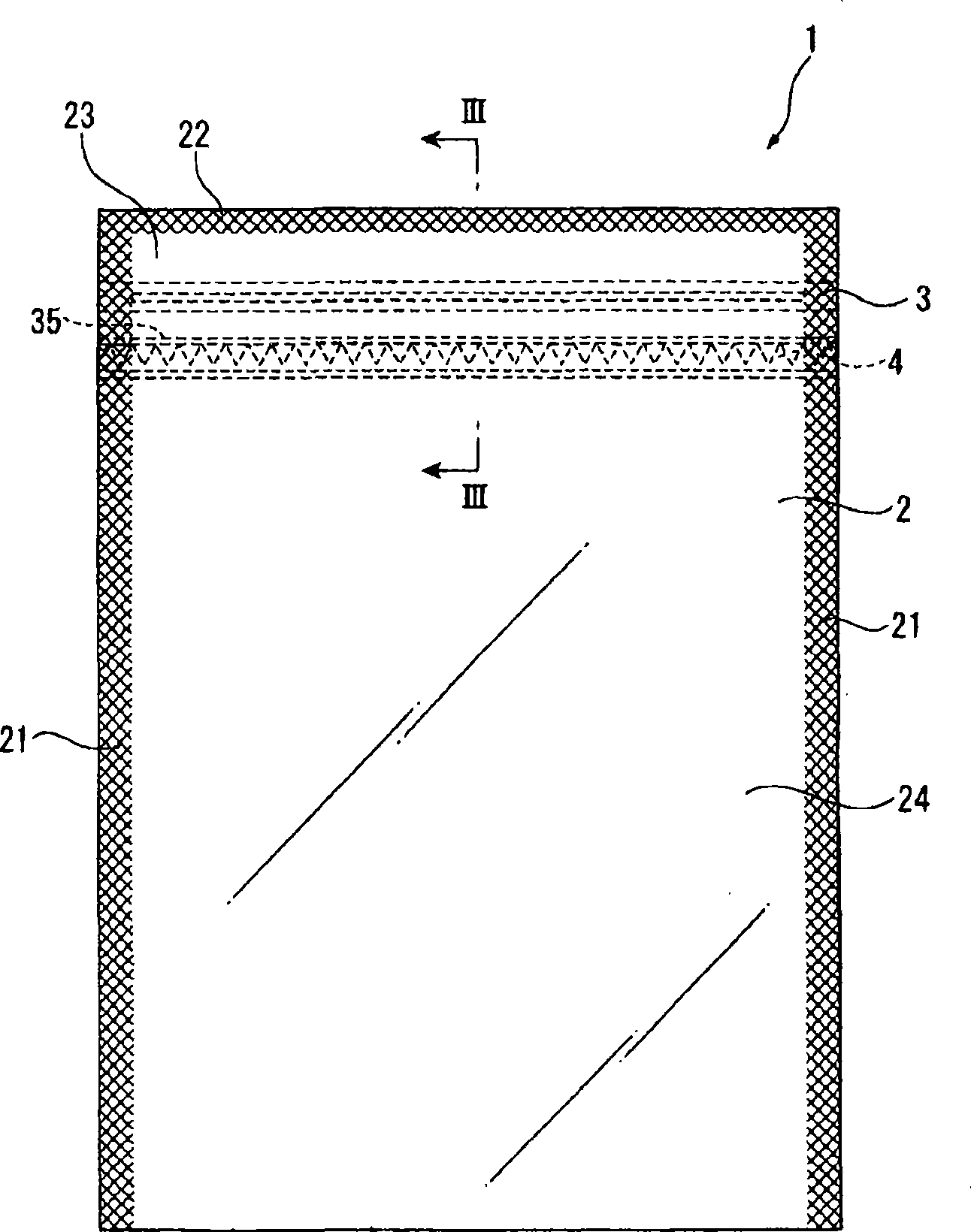

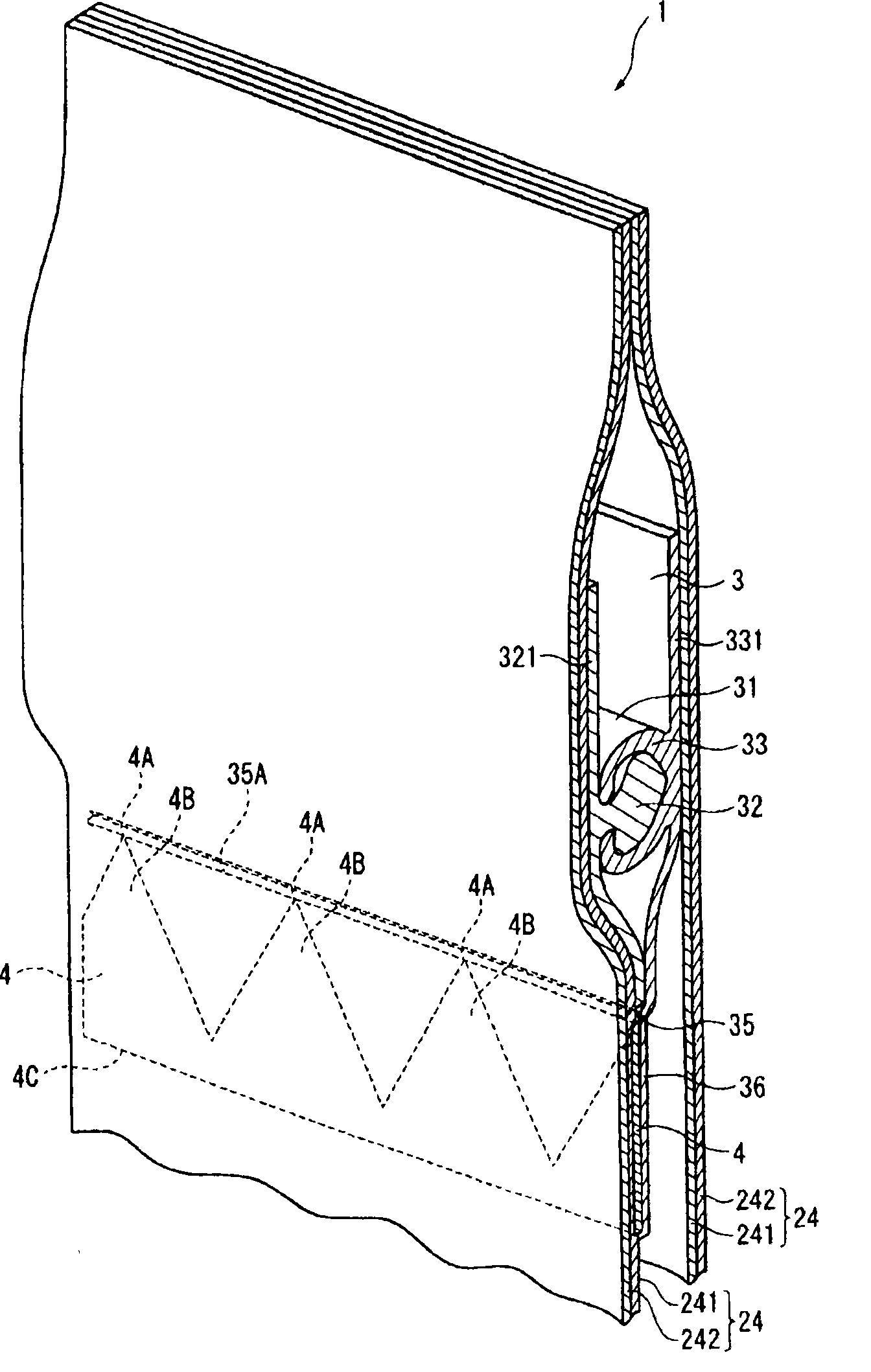

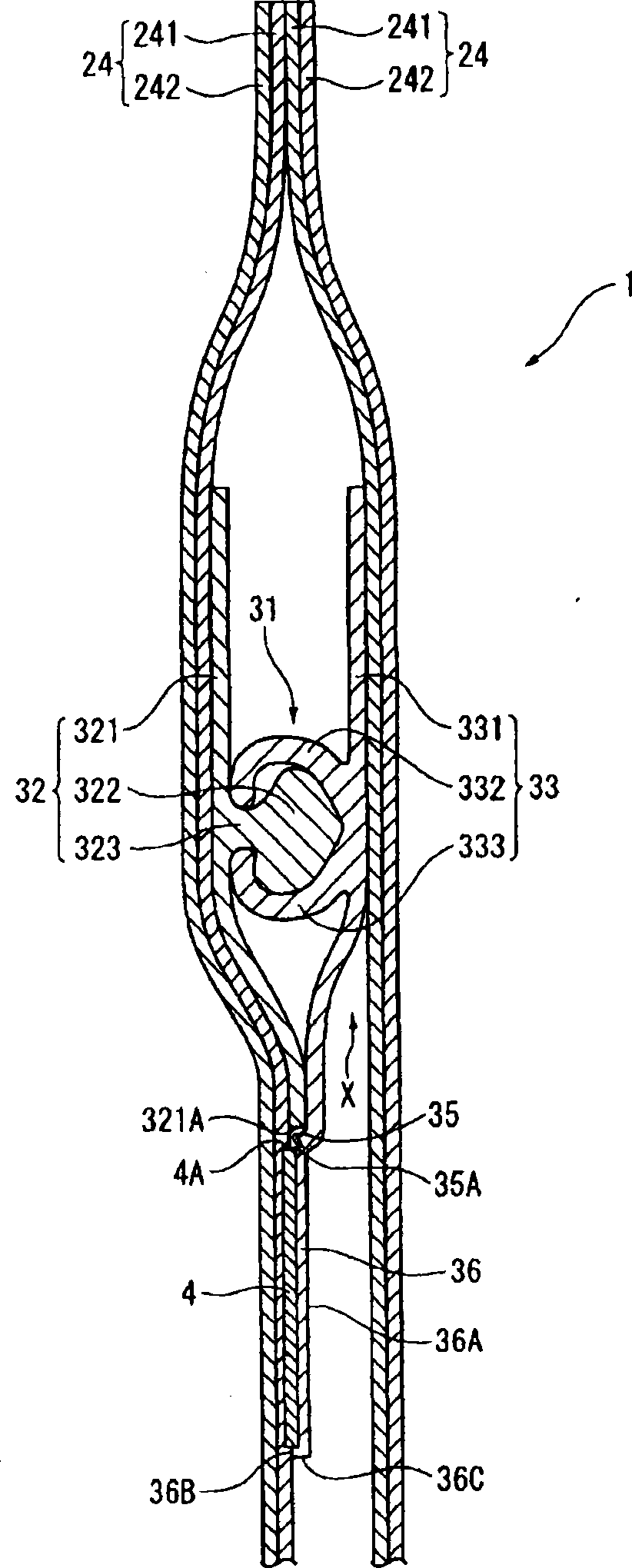

[0052] figure 1 It is a front view of the packaging bag with the zipper tape according to the first embodiment of the present invention, figure 2 yes figure 1 stereogram. image 3 yes figure 1 The cross-sectional view along line III-III is a cross-sectional view showing a state in which the zipper tape in which the seaming portion is engaged is sealed with respect to the bag body constituting the packaging bag.

[0053] Such as figure 1As shown, the packaging bag 1 with a zipper tape according to this embodiment has a bag body 2 formed by overlapping a base film 24 as a packaging material to form a side seal portion 21 and a front end seal portion 22 on its peripheral edge. form.

[0054] On the inner surface of the opening 23 of the bag body 2, a buckle belt 3 is installed, and the buckle belt 3 includes a pair of male parts 32 and female parts 33 ( figure...

no. 2 approach

[0101] Next, refer to Figure 9 to Figure 11 A second embodiment of the present invention will be described. In this embodiment, except for the configuration of the seal base 36 , other configurations are the same as those of the first embodiment, and thus description thereof will be omitted.

[0102] Such as Figure 9 As shown, in this embodiment, the sealing base 36 is made of a material having a lower melting point than the material used for the band-shaped base 331 located on the opening side of the linear portion 35 . For example, the sealing base 36 is made of atactic polypropylene (melting point 135°C), and the strip-shaped base 331 located closer to the opening than the linear portion 35 is made of polypropylene homopolymer (melting point 160°C). In addition, in the present embodiment, the sealing portion 4 has a shape such as Figure 11 A continuous convex shape as shown.

[0103] Figure 10 It is a diagram showing a state where the sealing base 36 and the inner ...

no. 3 approach

[0109] Next, a third embodiment of the present invention will be described. The configuration of this embodiment is the same as that of the first embodiment except for the configuration of the seal base 36 , so description thereof will be omitted.

[0110] Figure 12 It is a sectional view of the buckle belt 3 of this embodiment.

[0111] In the present embodiment, the material of the linear portion 35 and the material of the seal base 36 adjacent to the linear portion 35 are made of different materials with low compatibility.

[0112] For example, when polypropylene is used for the sealing base 36 , low-density polyethylene (LDPE) can be used for the linear portion 35 .

[0113] The sealing shape is the same shape as that of the above-mentioned second embodiment ( Figure 11 ), so the force is applied to the opening-side end 4A of the sealing portion 4 at the time of unsealing, so the force is also applied to the linear portion 35 in contact with the opening-side end 4A. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com