Corneal implants and methods and systems for placement

A cornea and implant technology, applied in eye implants, medical science, prostheses, etc., can solve the problem that the transmission system cannot be well adapted to the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

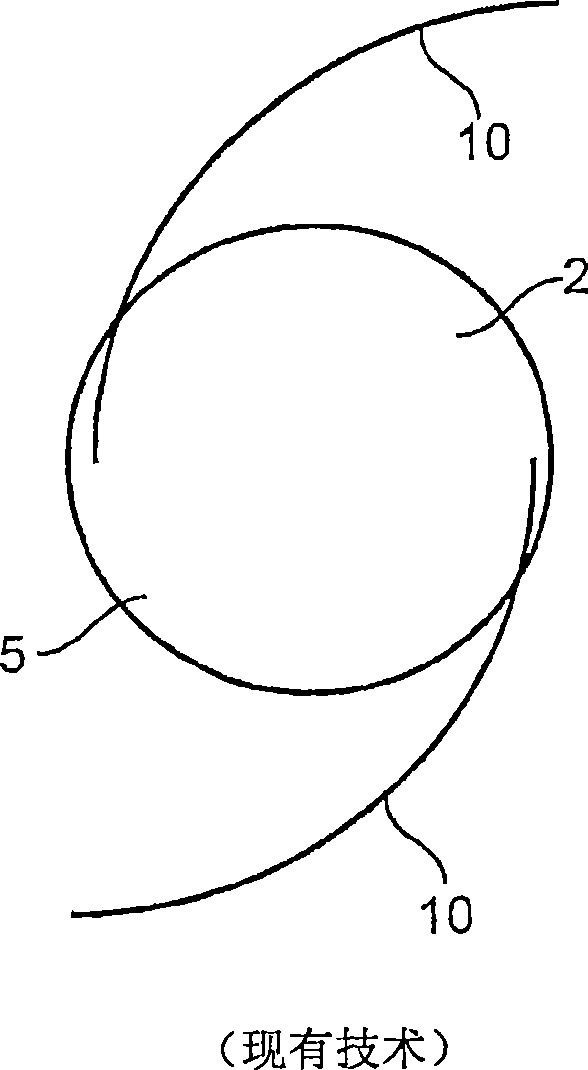

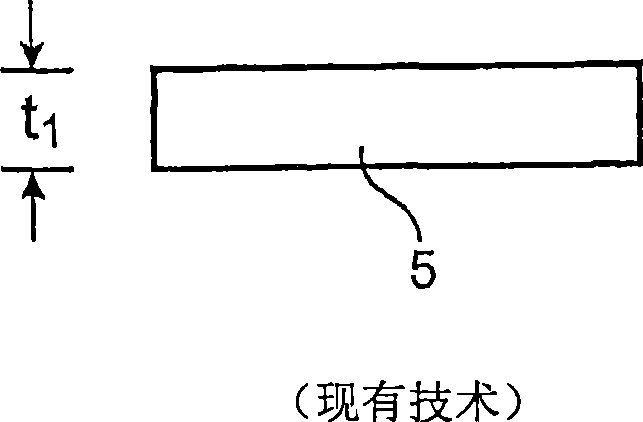

[0031] Figure 1A A top view of a cataract surgery lens implant 2 is shown. The circular optic 5 of the implant 2 has support feet 10 extending from the periphery of the optic. Support feet 10 are used to assist in centering and securing the optic within the pouch. Figure 1B A side view of the cataract surgery lens implant optics 5 is shown. Note that the thickness t of the optics 5 1 Typically 1 mm or more, and substantially greater than the thickness of the human cornea of 0.5 to 0.6 mm. The thickness of the optic 5 makes it unsuitable for use as a corneal lens implant. Figure 1C A top view of the corneal implant 15 is shown. Note that there are no supporting feet on the corneal implant. Figure 1D A side view of the corneal implant 15 is shown. Note that the thickness t 2 Sufficiently less than the thickness of the lens implant 5 for cataract surgery. The thickness t of the corneal implant 15 2 Usually it will be less than the thickness of the human cornea.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com