High-speed photoelectric subassembly and flip chip structure thereof

A technology for optoelectronic components and electronic chips, applied in electrical components, electro-solid devices, circuits, etc., can solve the problems of difficult to achieve product reliability indicators, difficult to adapt to higher speed requirements, difficult to effectively connect optical and electrical signals, etc. Achieve the effect of reducing the difficulty of development and production and the production cost of products, solving bottleneck problems, and effectively delivering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

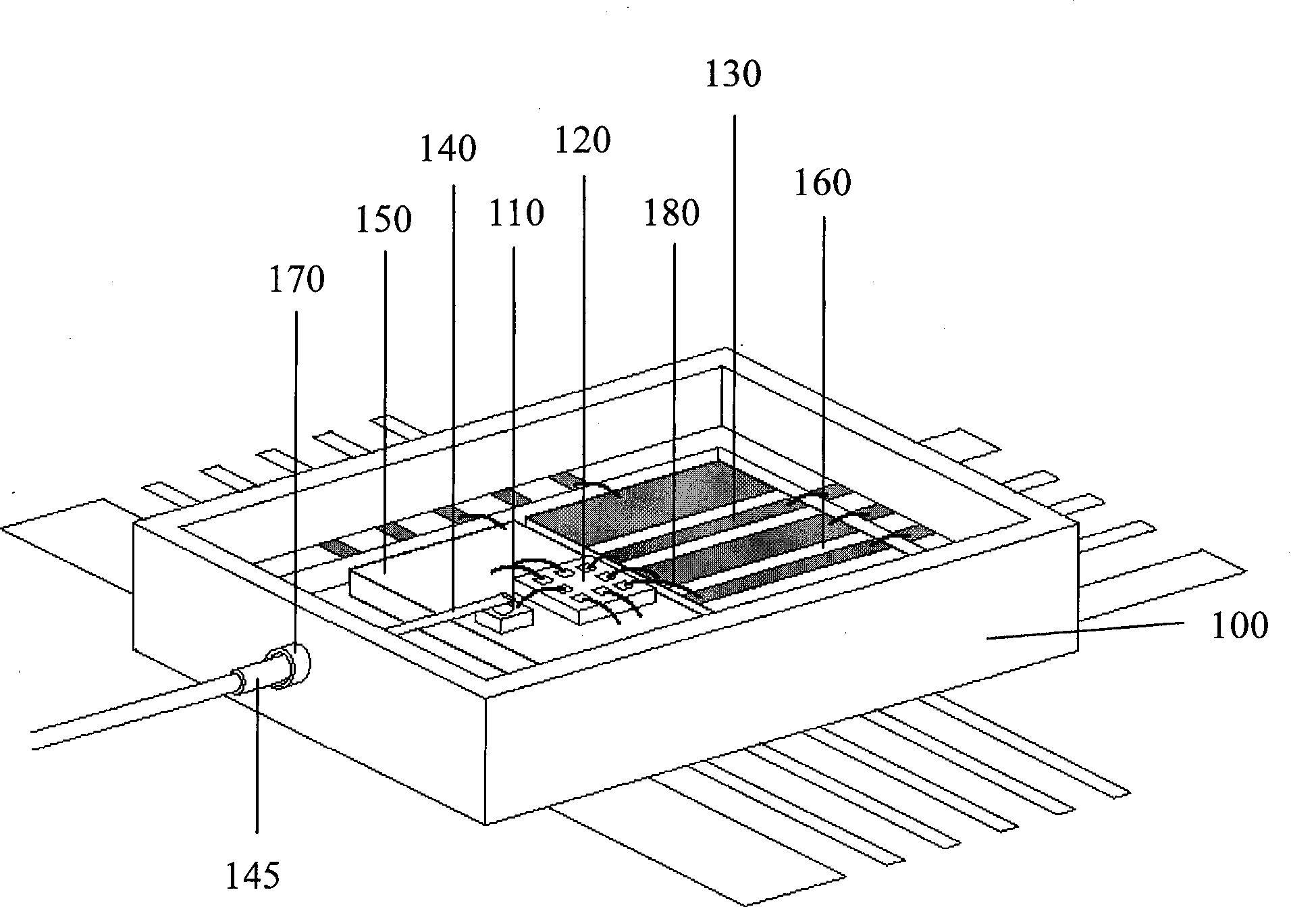

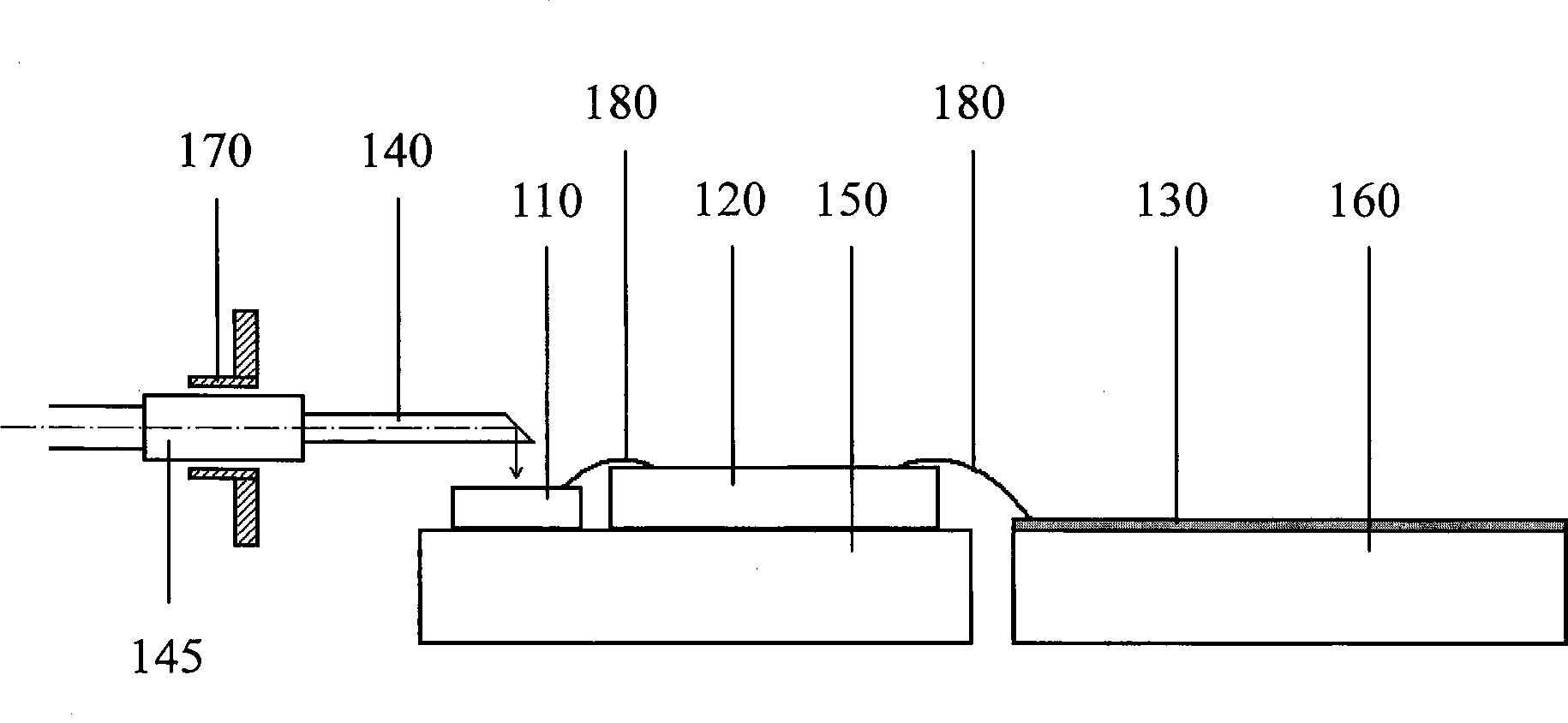

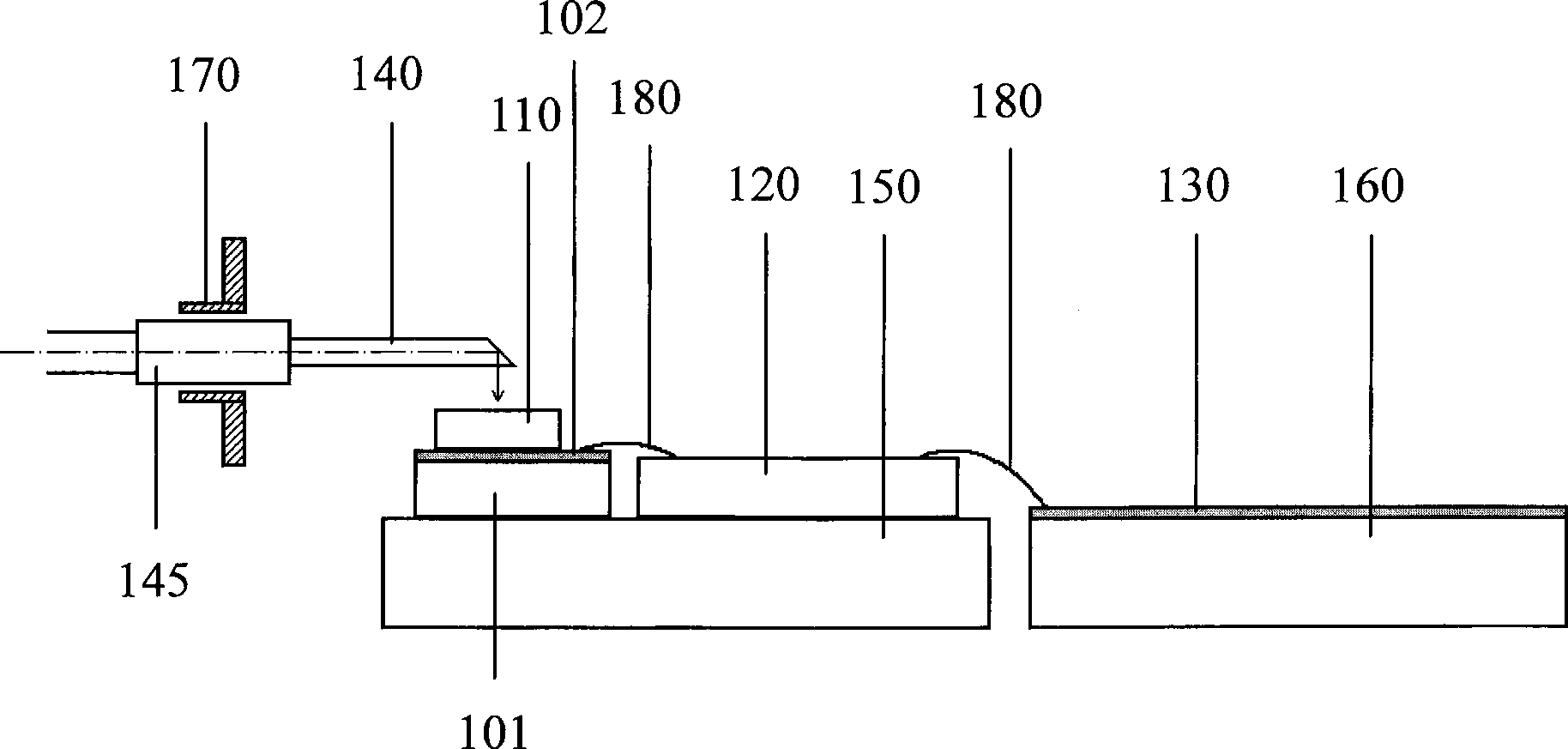

[0058] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0059] see Figure 4A and Figure 4B As shown, they are respectively the plane basic structure schematic diagram and the side basic structure schematic diagram of the chip flip chip structure of the present invention. The chip flip chip structure 200 includes: an insulating substrate 210; a photoelectric conversion chip 220, the flip chip surface of which passes through at least A pad 240a is connected to the insulating substrate 210; at least one associated electronic chip 230, whose flip-chip surface is connected to the insulating substrate 210 through at least one pad 240b, and connected to the photoelectric conversion chip 220 A high-speed transmission circuit 240c is provided between them; a high-speed transmission circuit 240d is provided between the associated electronic chip 230 and the high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com