Support bar mounting structure of automobile glass backdoor

A technology of automotive glass and installation structure, applied in the field of car body, can solve the problem of unable to meet the waterproof and impact resistance of glass back door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

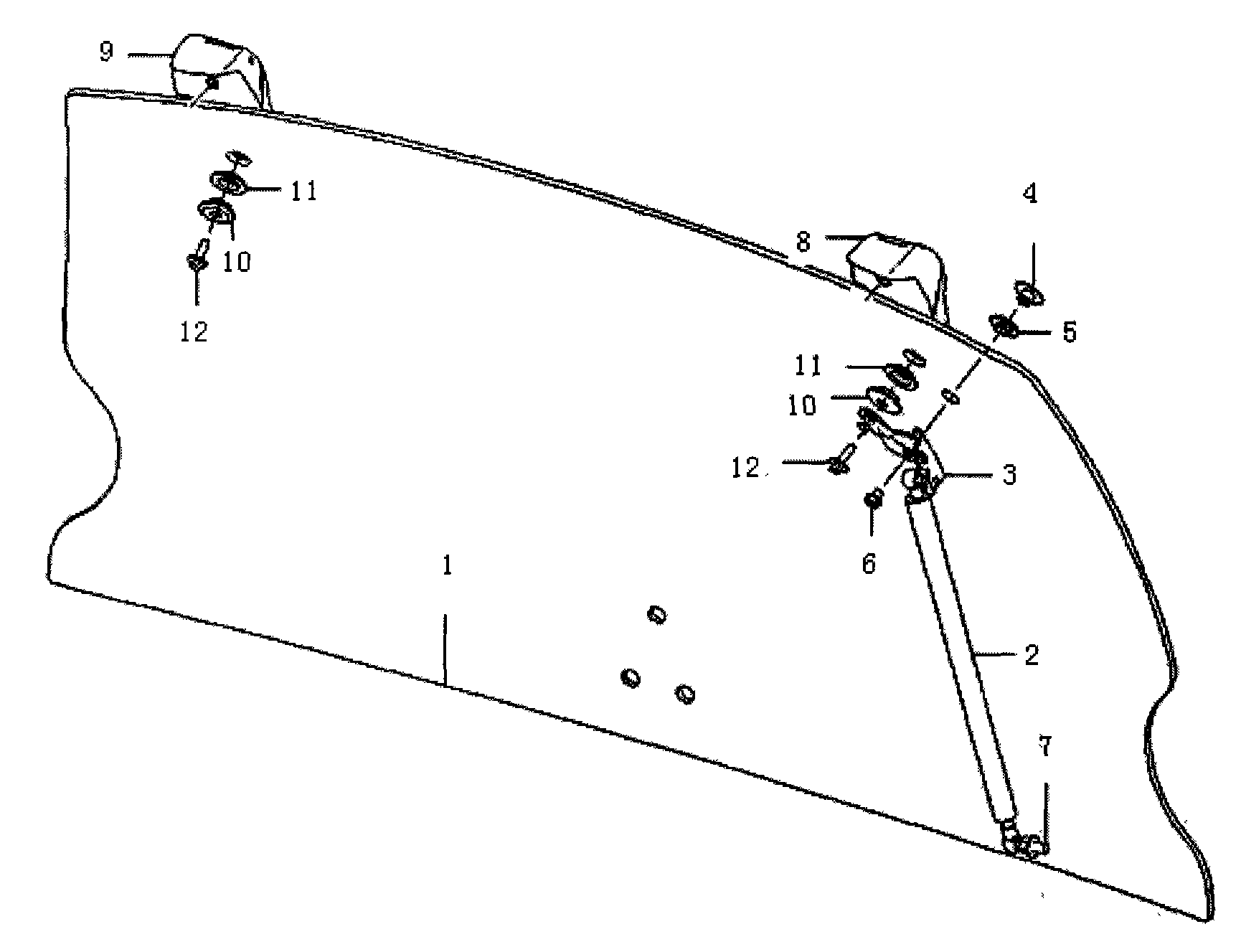

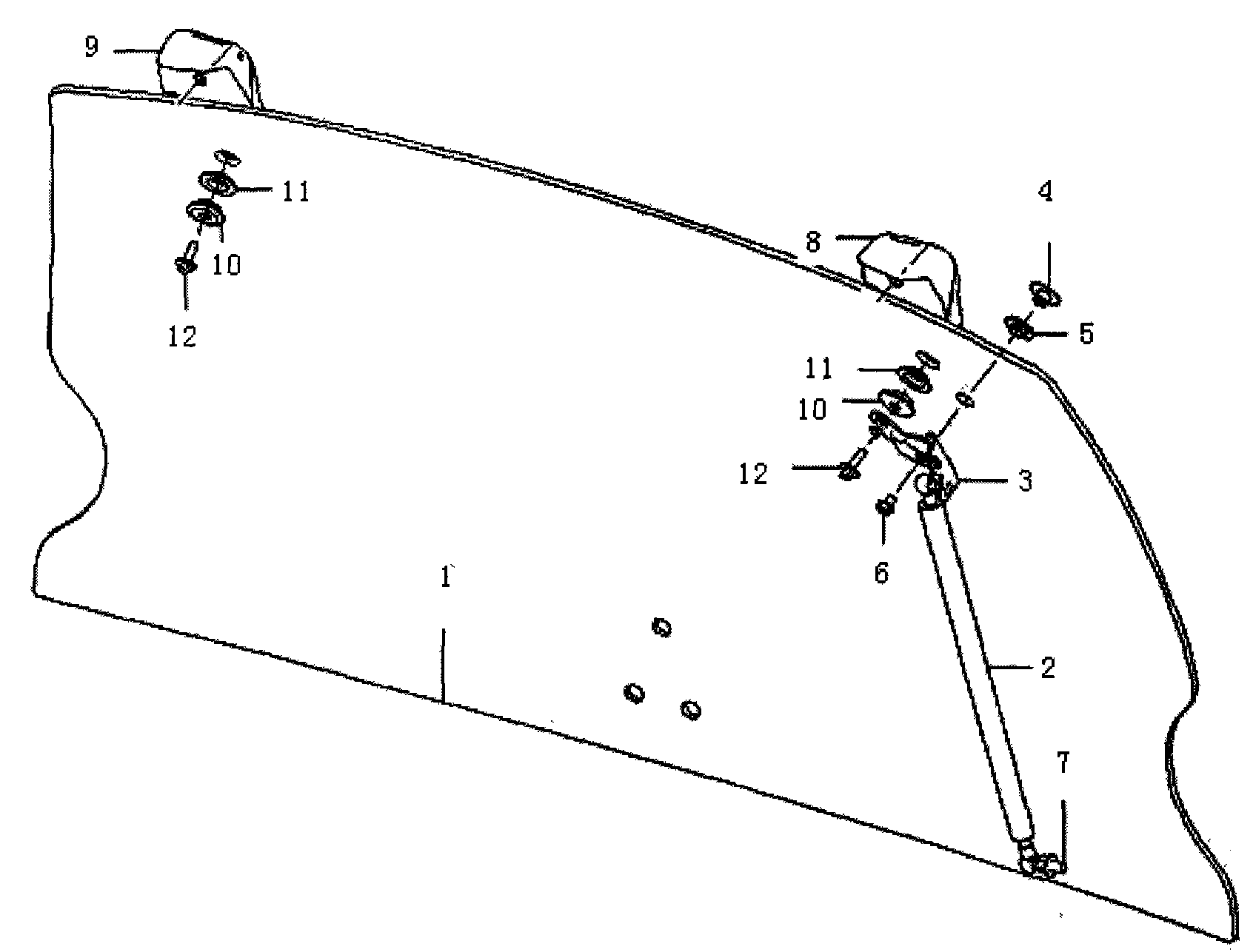

[0012] see figure 1 , the strut installation structure of the glass back door, it comprises glass back door 1, strut assembly 2, back door hinge assembly left 8 and back door hinge assembly right 9 etc. One end of the strut assembly 2 is assembled to the vehicle body through the ball stud 7, and the other end is installed on the glass back door 1 through the mounting plate assembly 3, and is assembled with the left 8 of the back door hinge assembly at the corresponding position at the same time.

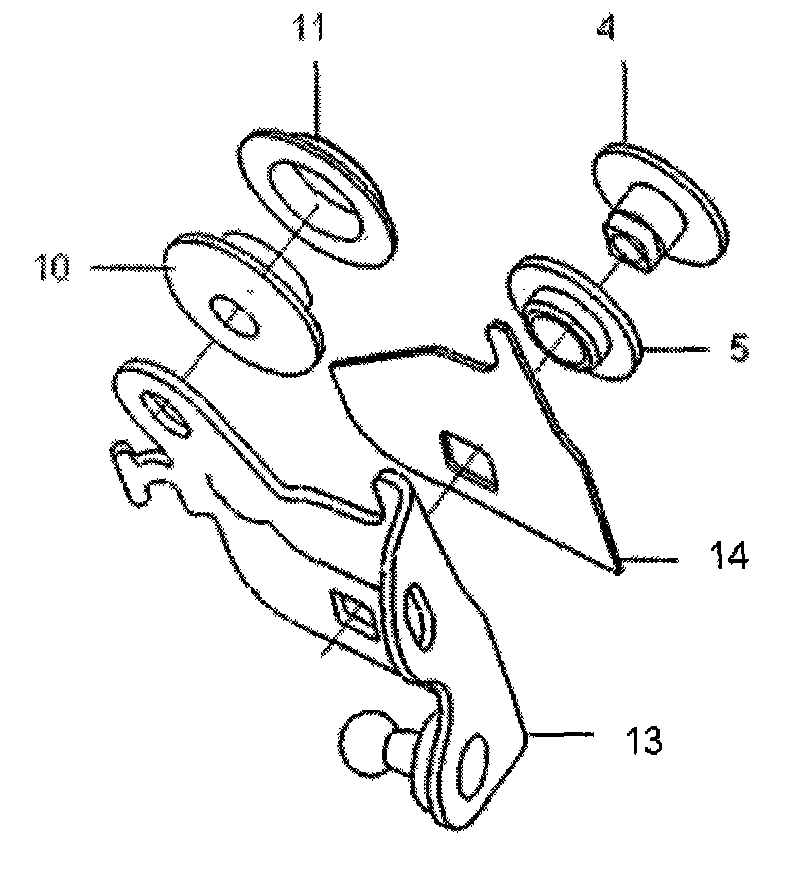

[0013] combine figure 2 It can be seen that the installation plate assembly 3 includes the installation plate 13, the installation nut 4, the installation round table 10, the bolt A6 and the bolt B12, etc., a part of the installation plate 13 is assembled with the end of the strut assembly 2, and the other part is connected with the glass back door 1. There are two mounting holes on it, one is an oblong hole and the other is a square hole, corresponding to the two holes on the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com