Decorative sheet

A decorative sheet and protective layer technology, which is applied in the field of decorative boards, can solve the problems of resistance to pollution, leakage of silicone modified resin, etc., and achieve the goals of avoiding leakage, excellent pollution resistance and durability, and excellent design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

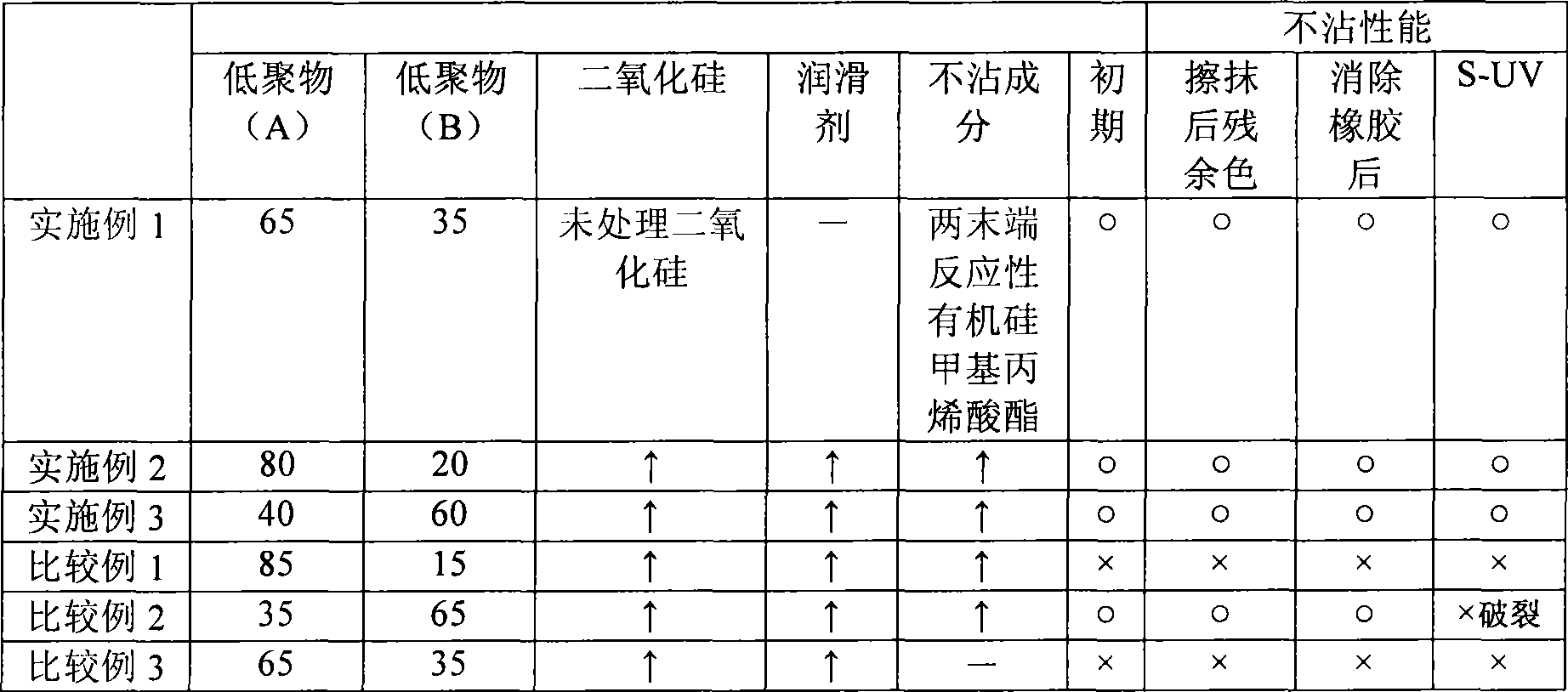

Examples

Embodiment 1~3

[0141] As a substrate sheet, a polypropylene-based resin film (thickness: 60 μm, transmittance: 10%) was prepared. After corona discharge treatment was applied to the surface and the back surface, a woodgrain pattern layer was formed on the surface by gravure printing. On the other hand, on the back side, an undercoat layer was formed by gravure printing.

[0142] Next, a coating liquid composed of a two-component curing type polyurethane resin was coated on the pattern layer to form an adhesive layer (thickness: 3 μm). Then, a polypropylene-based thermoplastic elastomer composed of an ethylene-propylene-butene copolymer was melt-extruded and coated with a T die to form a transparent resin layer (thickness: 80 μm).

[0143] A two-component curable polyurethane-based resin consisting of acrylic-urethane block polymer (main agent) and hexamethylene diisocyanate (curing agent) is coated on the transparent resin layer to form a primer layer (thickness 2 μm) .

[0144] Next, usi...

Embodiment 4

[0168] A polypropylene-based resin film (thickness: 60 μm, transmittance: 10%) was prepared as a base material sheet. After corona discharge treatment was applied to the surface and the back surface, a woodgrain pattern layer was formed on the surface by gravure printing. On the other hand, an undercoat layer is formed on the back surface by gravure printing.

[0169] Next, a coating liquid composed of a two-component curing type polyurethane resin was coated on the pattern layer to form an adhesive layer (thickness: 3 μm). Then, a polypropylene-based thermoplastic elastomer composed of an ethylene-propylene-butene copolymer was melt-extruded and coated with a T die to form a transparent resin layer (thickness: 80 μm).

[0170] An undercoat layer is formed on the transparent resin layer. The undercoat layer is formed by coating a substance containing 25% by weight of an antistatic agent (quaternary ammonium salt) and 30% by weight of an antistatic agent (barium sulfate) on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com