Automatic oil pipe conveying appliance

An automatic conveying device and oil pipe technology, applied in the direction of automatic/semi-automatic lathes, turning equipment, tool holder accessories, etc., can solve the problems of unstable movement, low efficiency, single function, etc., achieve compression loading and unloading time, and improve product quality , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

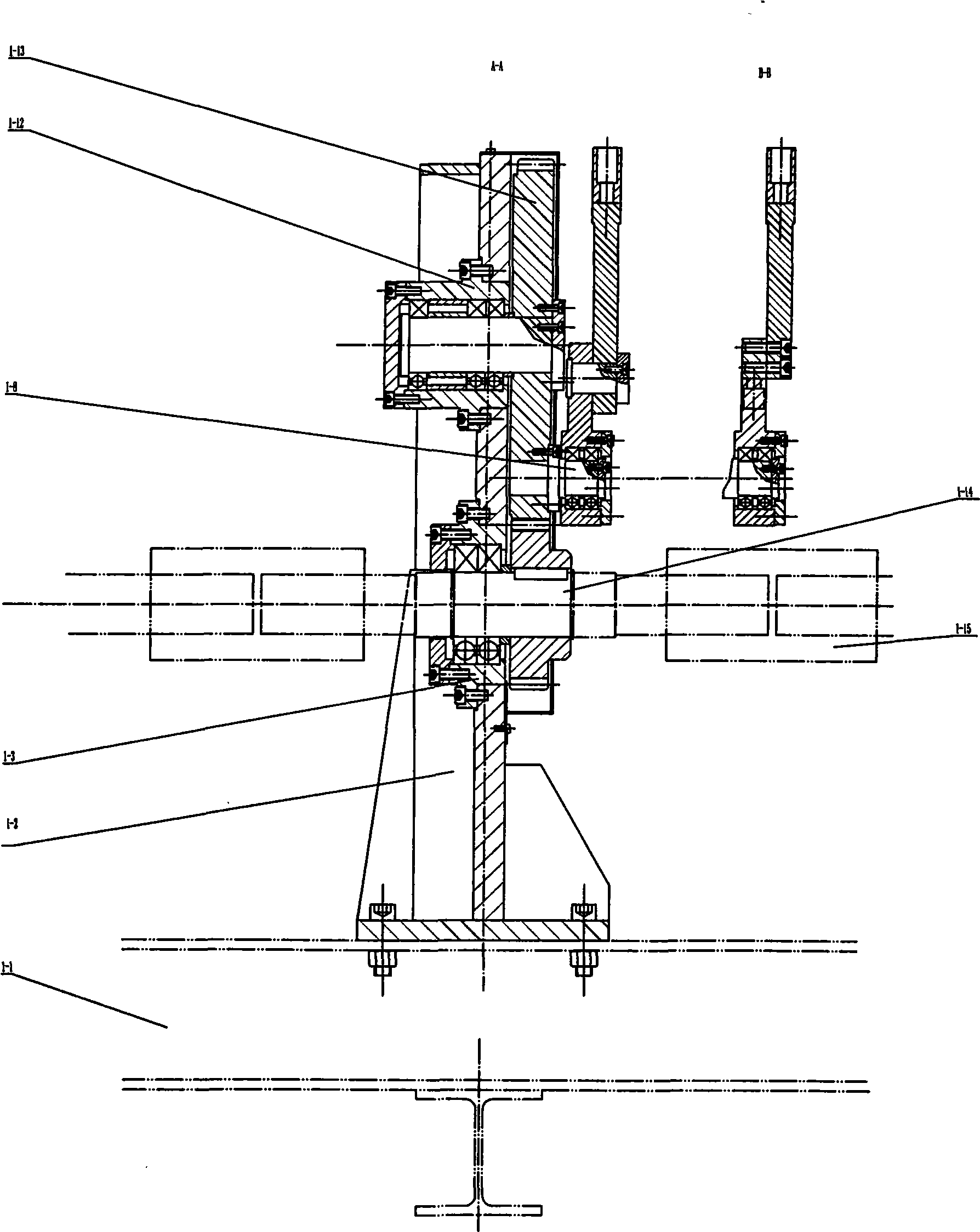

[0024] Below in conjunction with accompanying drawing, structure of the present invention is described in more detail:

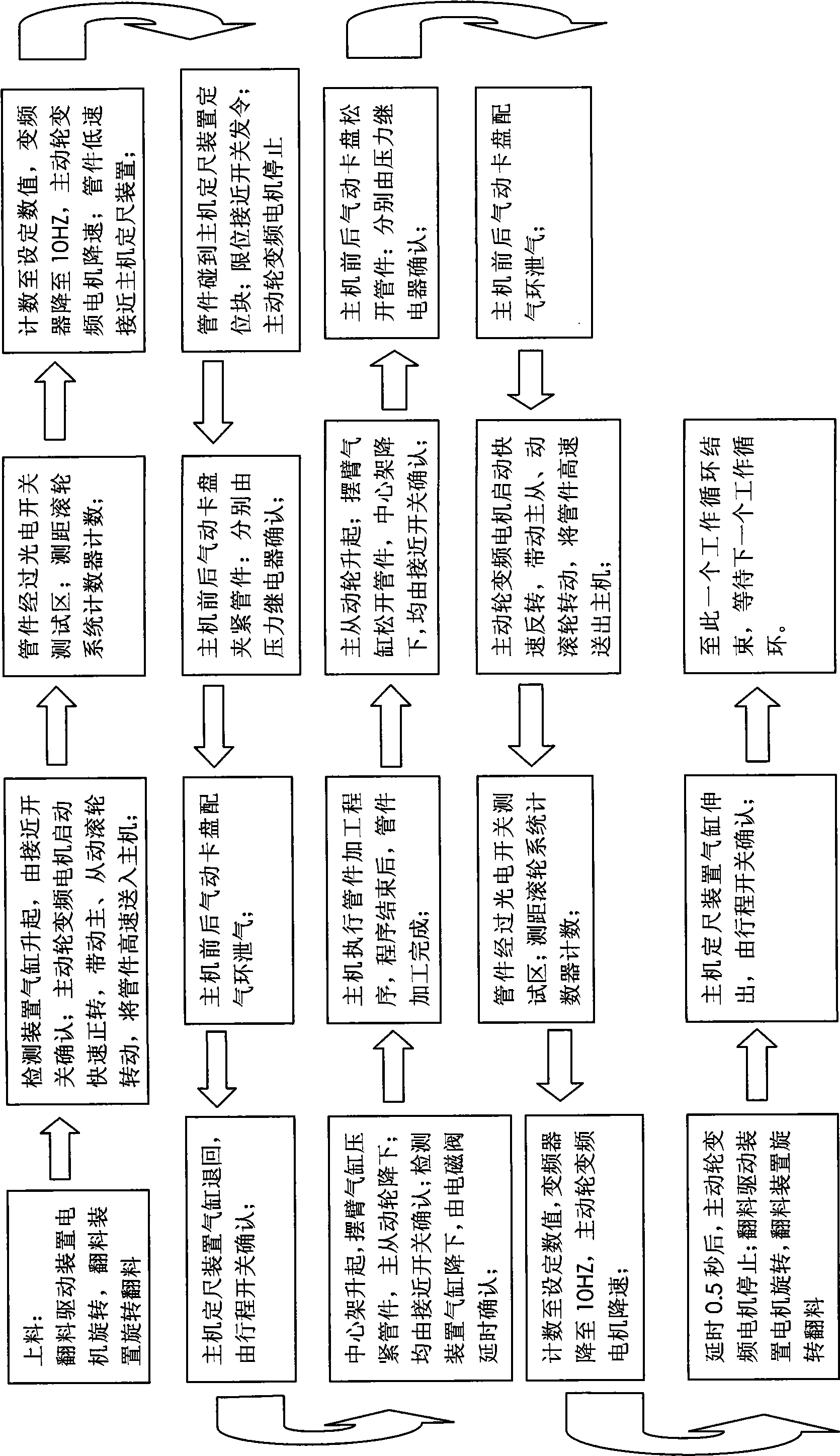

[0025] figure 1 The sequence in which the invention works is given;

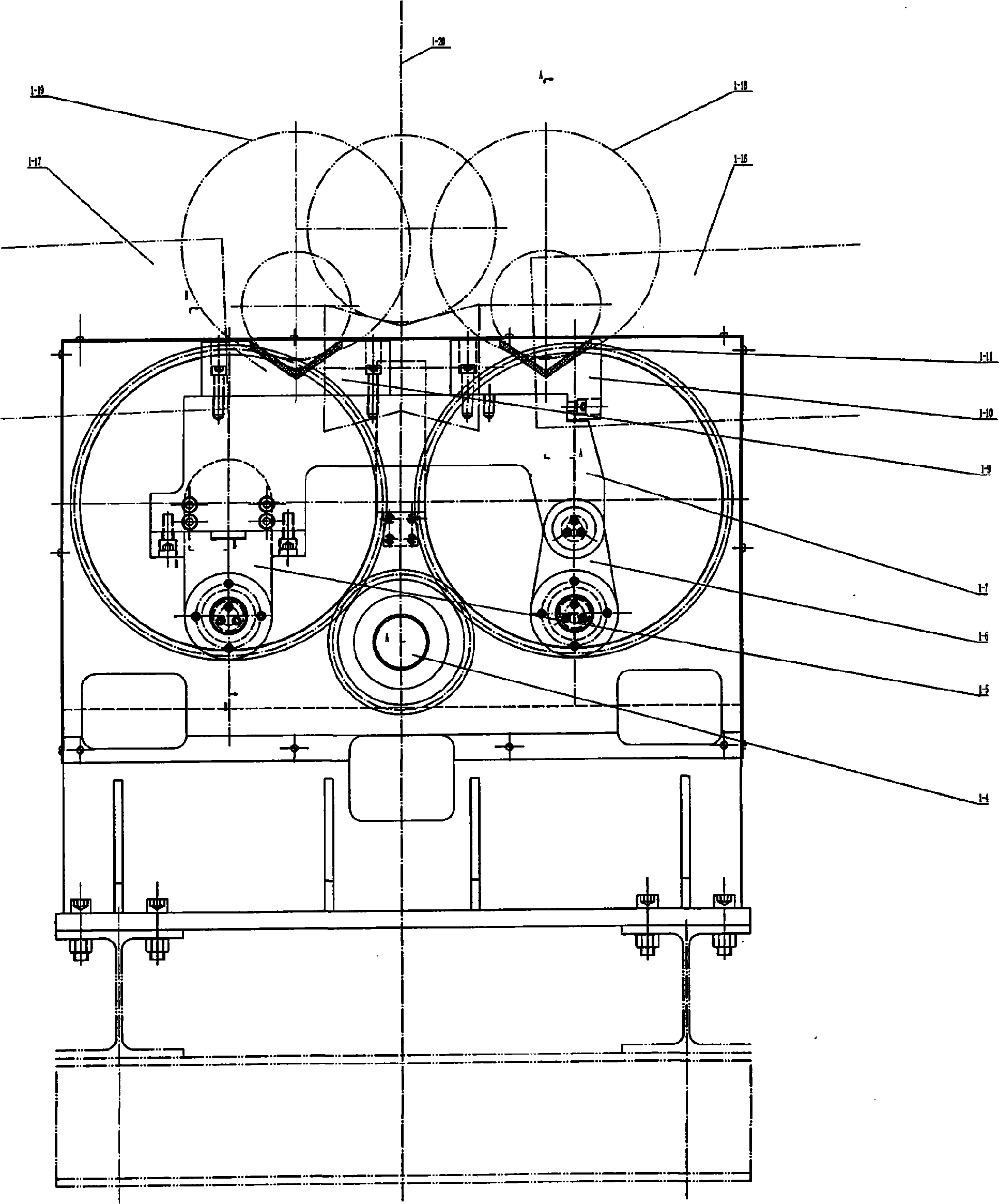

[0026] The present invention consists of five parts: a walking beam device, a central beam device, a driving wheel device, a driven wheel device, and a detection device; the four parts are supported by a beam to realize the action of each part.

[0027] The part of the walking beam device is shown in Figure 2, and the codes in the figure are respectively: Yan beam device (1-1), walking beam base (1-2), pinion bearing housing (1-3), pinion (1 —4), support arm (1-5), connecting arm (1-6), feeding plate (1-7), small shaft (1-8), left V-shaped plate (1-9), right V Shaped plate (1-10), damping rubber strip (1-11), large gear bearing seat (1-12), large gear (1-13), transmission shaft (1-14), coupling (1- 15), feed frame (1-16), discharge frame (1-17), right V-shaped plate motion track (1-18),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com