Water vapour plasma burner and method of wear detection and process control in the case of such a water vapour plasma burner

A technology of plasma welding and detection method, applied in the direction of plasma welding equipment, plasma, welding equipment, etc., can solve the problems of not considering the heat of the cathode, damage, affecting the temperature control of the evaporator, etc., to achieve stability and quality without affecting, Extends service life and eliminates the effects of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] First, it is to be noted that the same components in the embodiments are denoted by the same reference numerals.

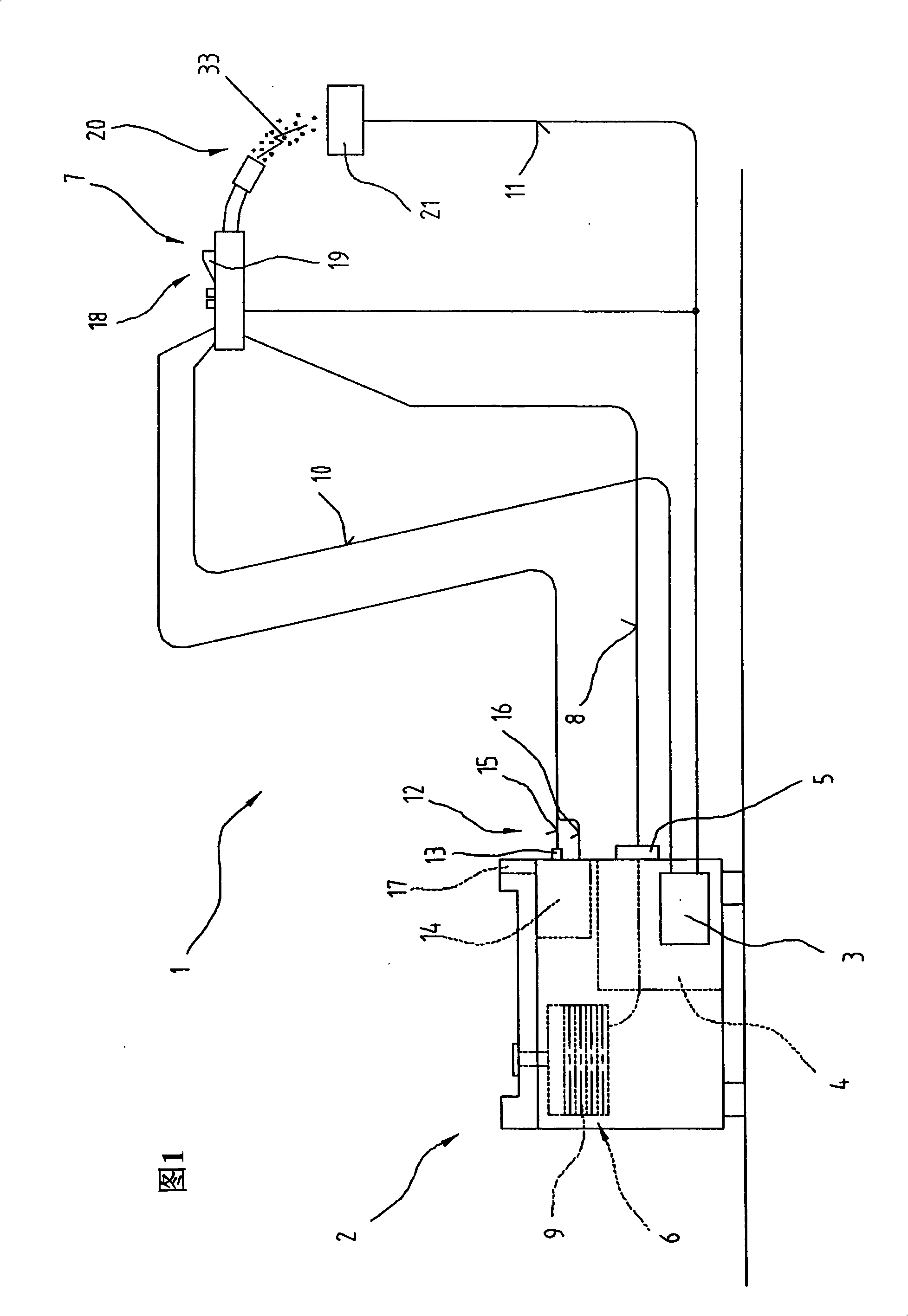

[0033] figure 1 Shown is a steam cutting device 1 with a base unit 2 for performing a steam cutting process. The base unit 2 comprises a current source 3 , a control unit 4 and a blocking element 5 assigned to the control unit 4 . The blocking element 5 is connected to the reservoir 6 and the steam plasma torch 7 via a feed line 8 so that the liquid medium or liquid 9 in the reservoir 6 can be supplied to the steam plasma torch 7 . The water vapor plasma torch 7 is supplied with electrical energy via lines 10 , 11 connected to a current source 3 .

[0034] In order to cool the water vapor plasma torch 7, the torch is connected via a cooling circuit 12 to a liquid reservoir 14, between which a flow controller 13 may be interposed. When the welding torch 7 or the steam cutting device 1 is put into operation, the control unit 4 can activate the cooling circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com