Ratchet swinging magnetic engine

A magnetic motor and magnet technology, applied in the direction of generators/motors, electromechanical devices, electric components, etc., can solve the problems of high switching energy consumption, pollute the environment, hinder the rotation of the flywheel, etc., and achieve the effect of low switching energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

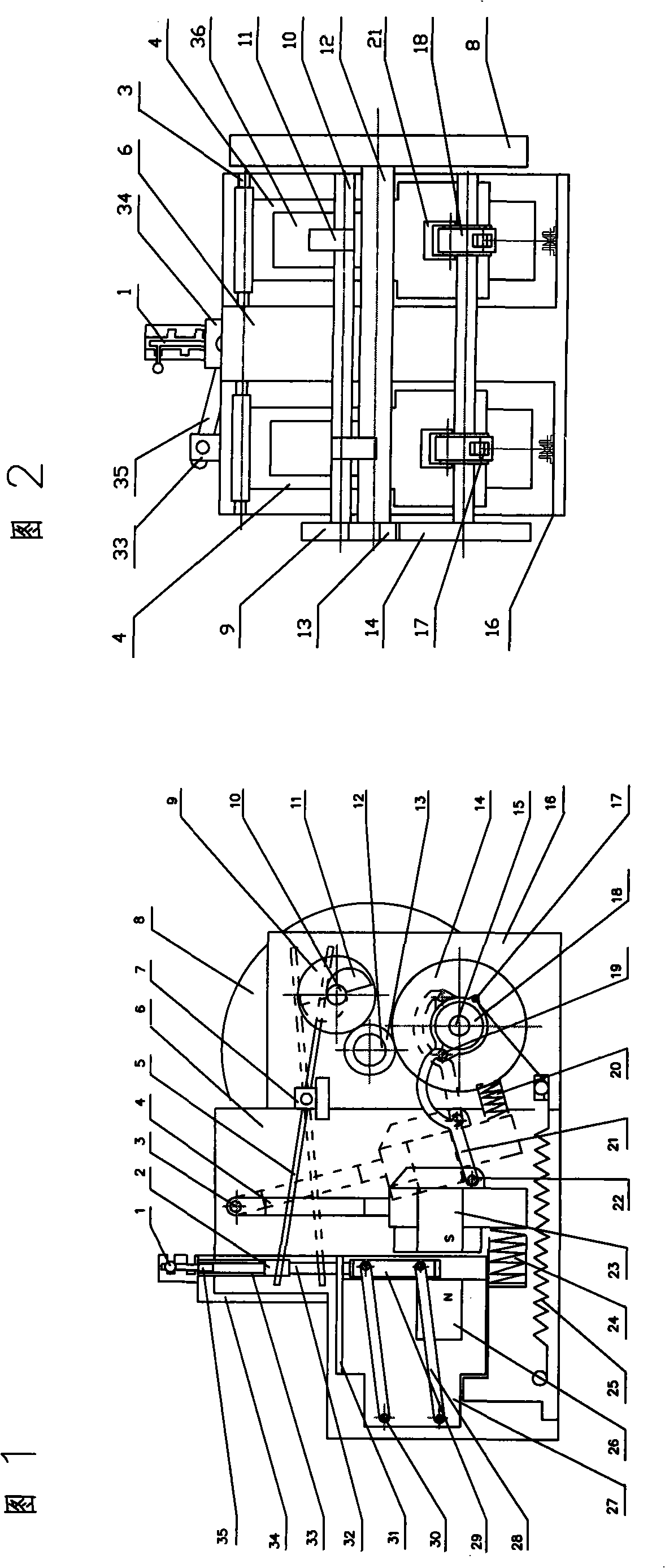

[0029] The specific implementation method (the present embodiment is a twin-cylinder engine)

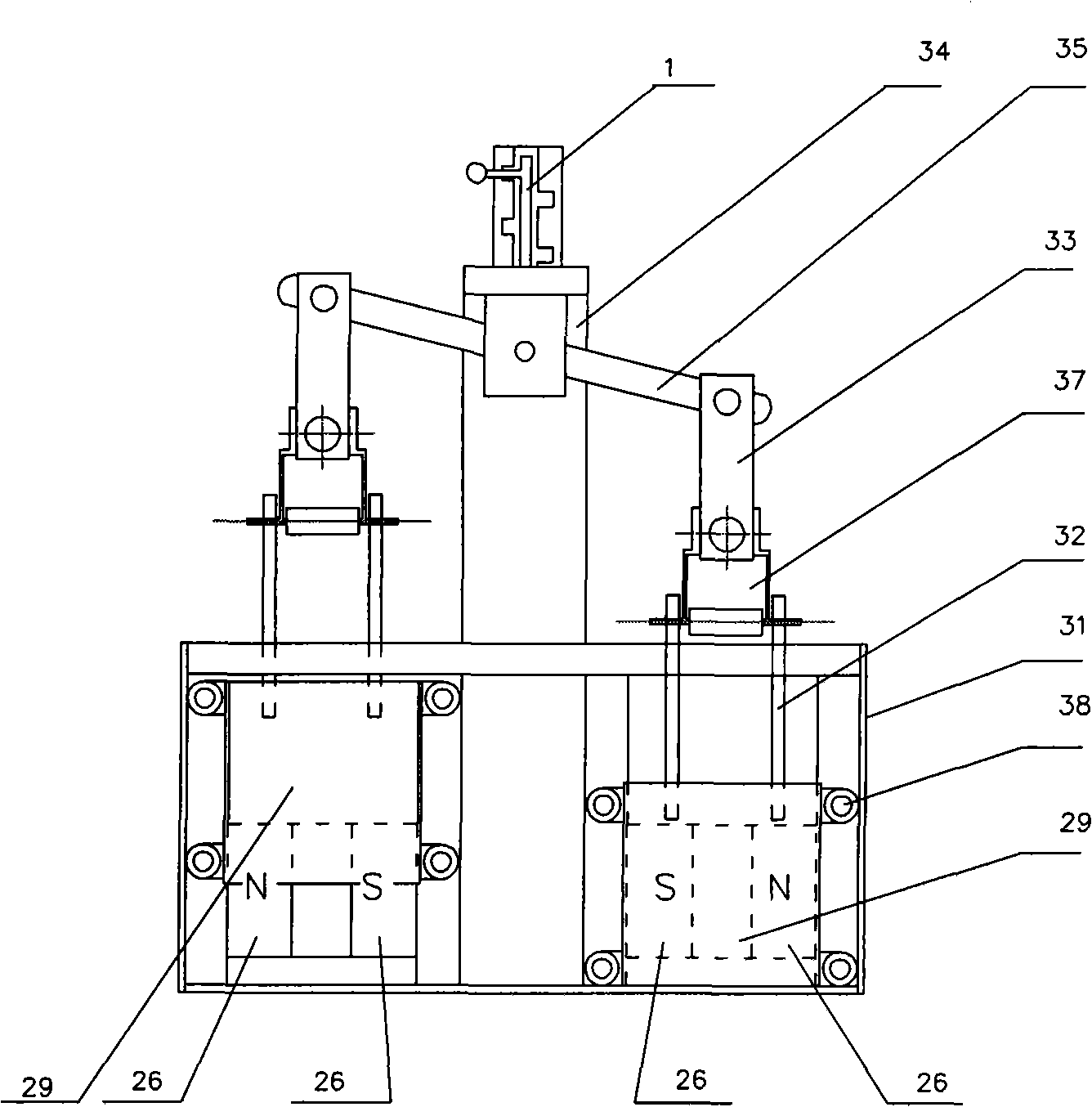

[0030] 1. Install two hoof-shaped strong magnets and accessories on the middle and lower parts of the two pendulums respectively to form two magnetic pendulum assemblies. The magnetic pendulum is installed in the pendulum frame with the pendulum pin so that the magnetic pendulum can Swing back and forth. The backs of the middle and lower parts of the two pendulums are respectively connected to a "bow-shaped connecting rod" with connecting rod pins, and the connecting rods are respectively connected to the two ratchet wheels of the ratchet shaft with ratchet connecting rod pins.

[0031] 2. Install the other two hoof-shaped strong magnets and accessories in parallel in the suction seat frame to form a "magnetic suction seat" assembly. A switch slot is left in front of the poles of the two magnets, and a movable magnetic isolation plate assembly is installed in each slot as a disconne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com