Capacity varying device for a scroll compressor

A technology for scroll compressors and changing devices, which is applied in the direction of elastic fluid rotary piston type/swing piston type pump combination, rotary piston type machinery, mechanical equipment, etc., and can solve the problem of increased compressor size, expensive components, Control complexity and other issues to achieve the effect of reducing the overall size, simplifying and compacting the structure and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

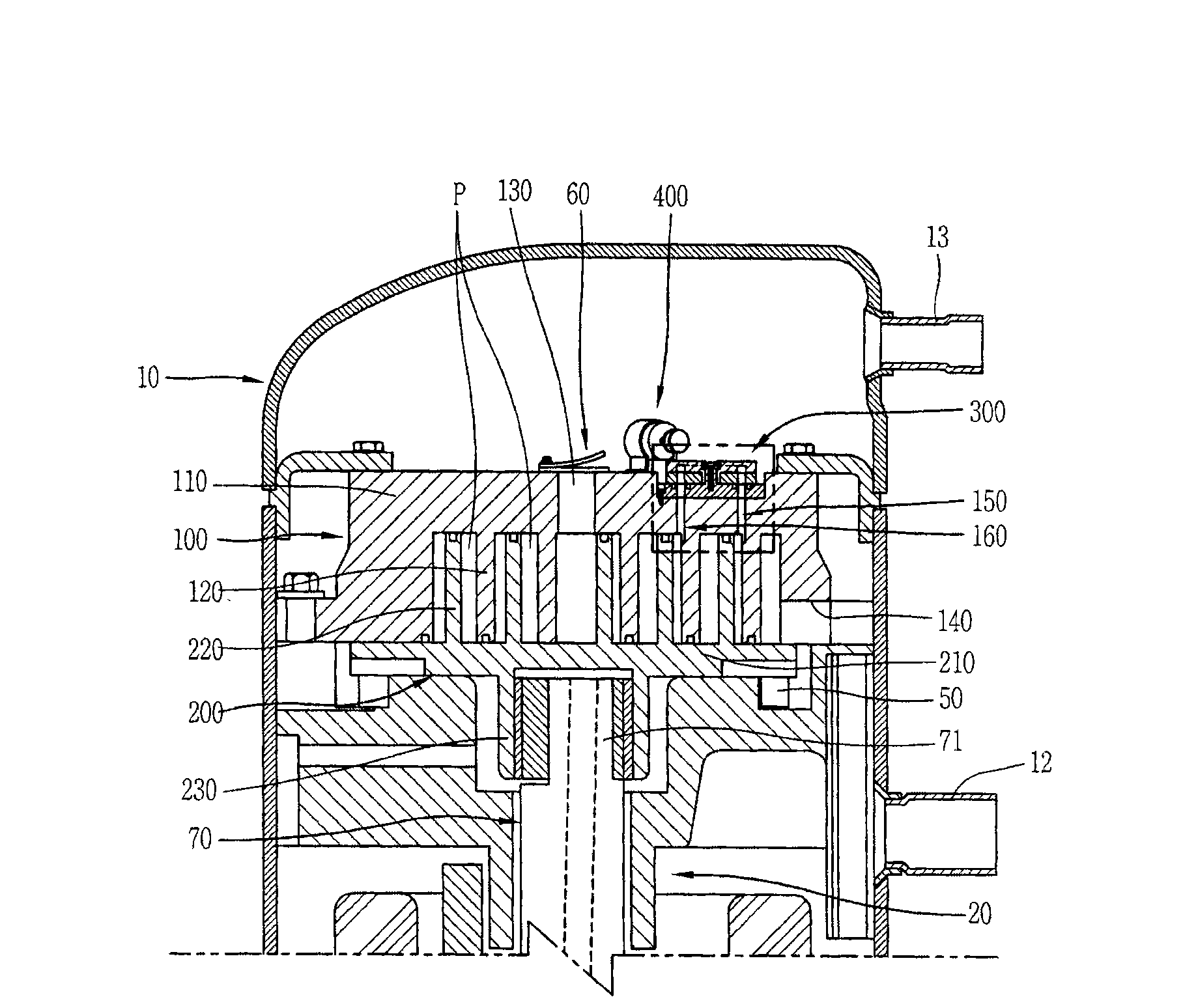

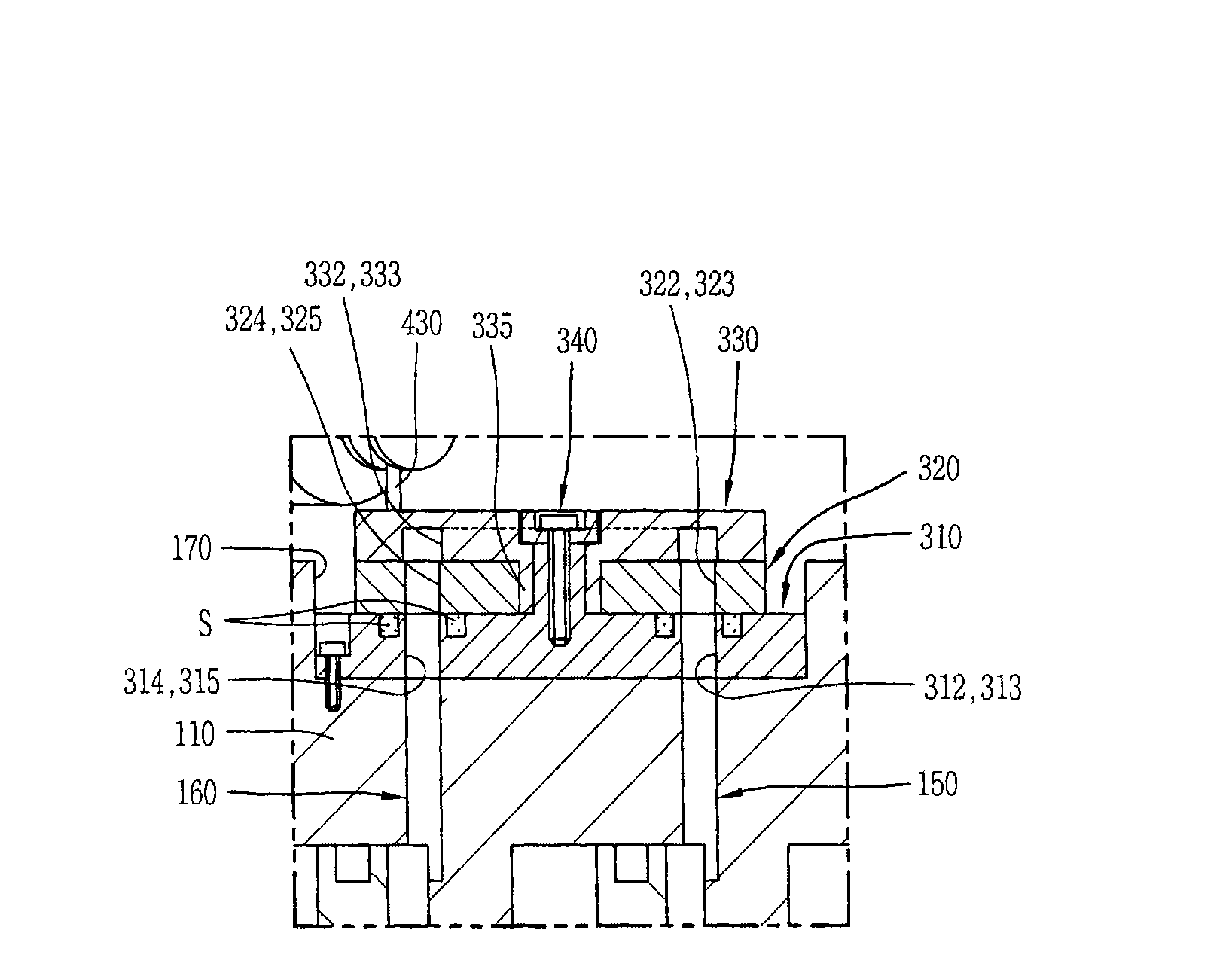

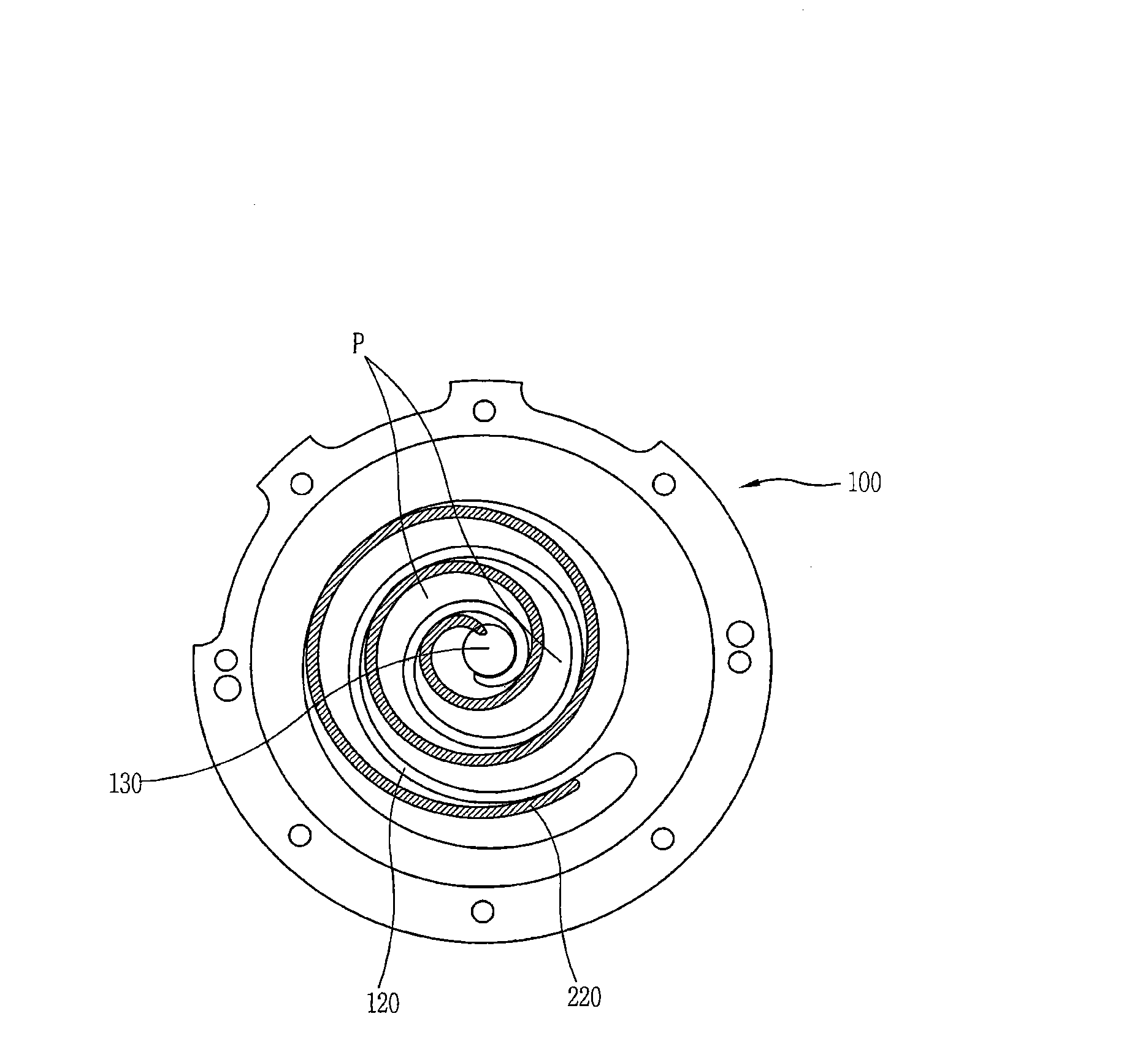

[0031] A capacity changing device for a scroll compressor according to an embodiment will now be described in detail with reference to the accompanying drawings. Where possible, the same reference numerals are used to refer to the same components.

[0032] Figure 1A to Figure 1B It is a front view showing a compression portion of a scroll compressor having a capacity changing device for a scroll compressor according to an embodiment. figure 2 yes Figure 1A to Figure 1B A plan view of the fixed scroll wrap and the orbiting scroll wrap in the compression part of the scroll compressor. image 3 is a plan view of a compression portion of a scroll compressor having a capacity changing device according to an embodiment. Figure 4 is an exploded view of a capacity changing device for a scroll compressor according to an embodiment. Figure 5 is showing Figure 4 Perspective view of the capacity changing device in assembled state.

[0033] will now refer to Figure 1A to Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com