Thread take-up lever structure of sewing machine

A thread take-up lever and sewing machine technology, applied in the field of sewing machine parts, can solve the problems of suture detachment, inconvenient thread entry, and detachment of sutures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

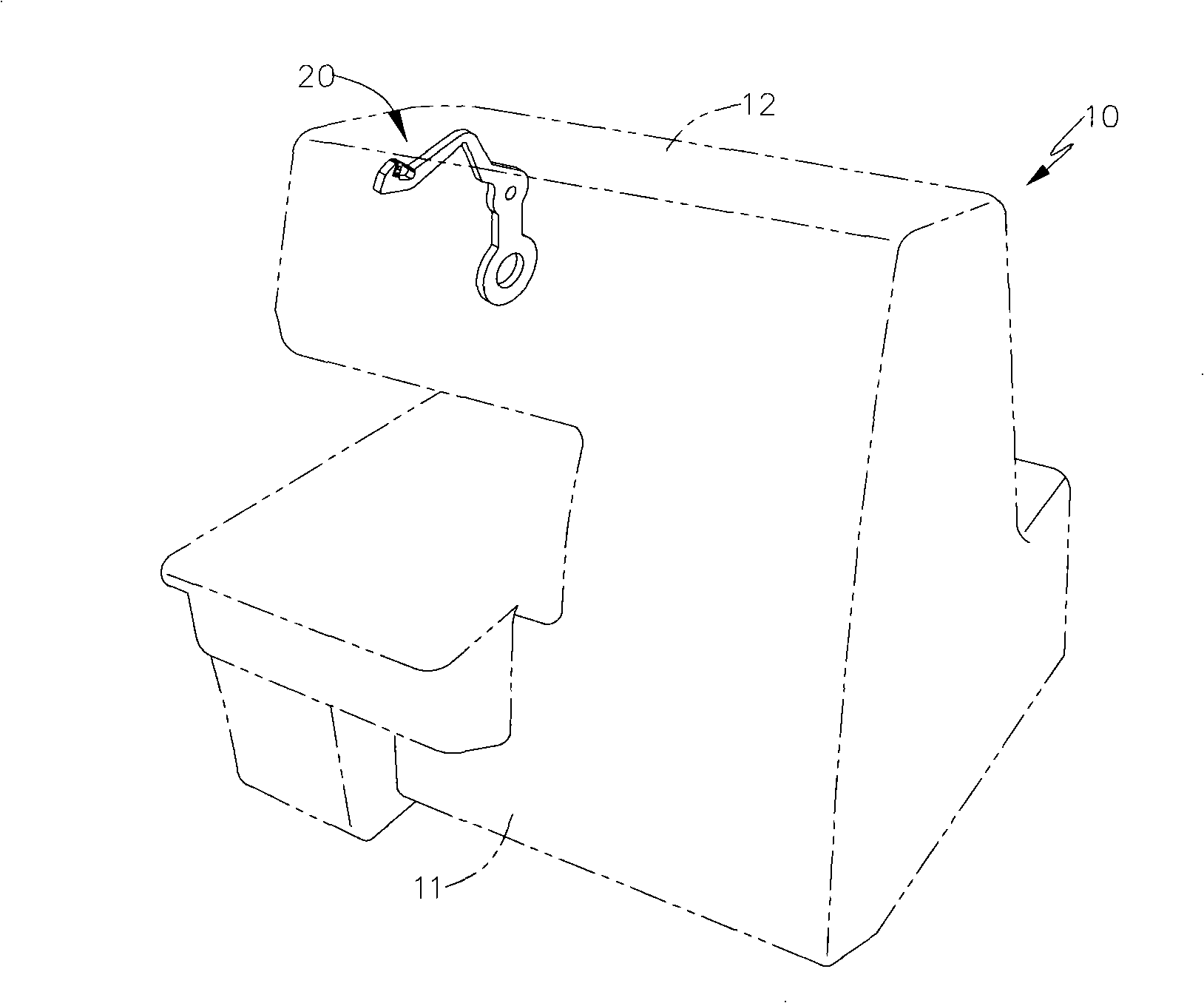

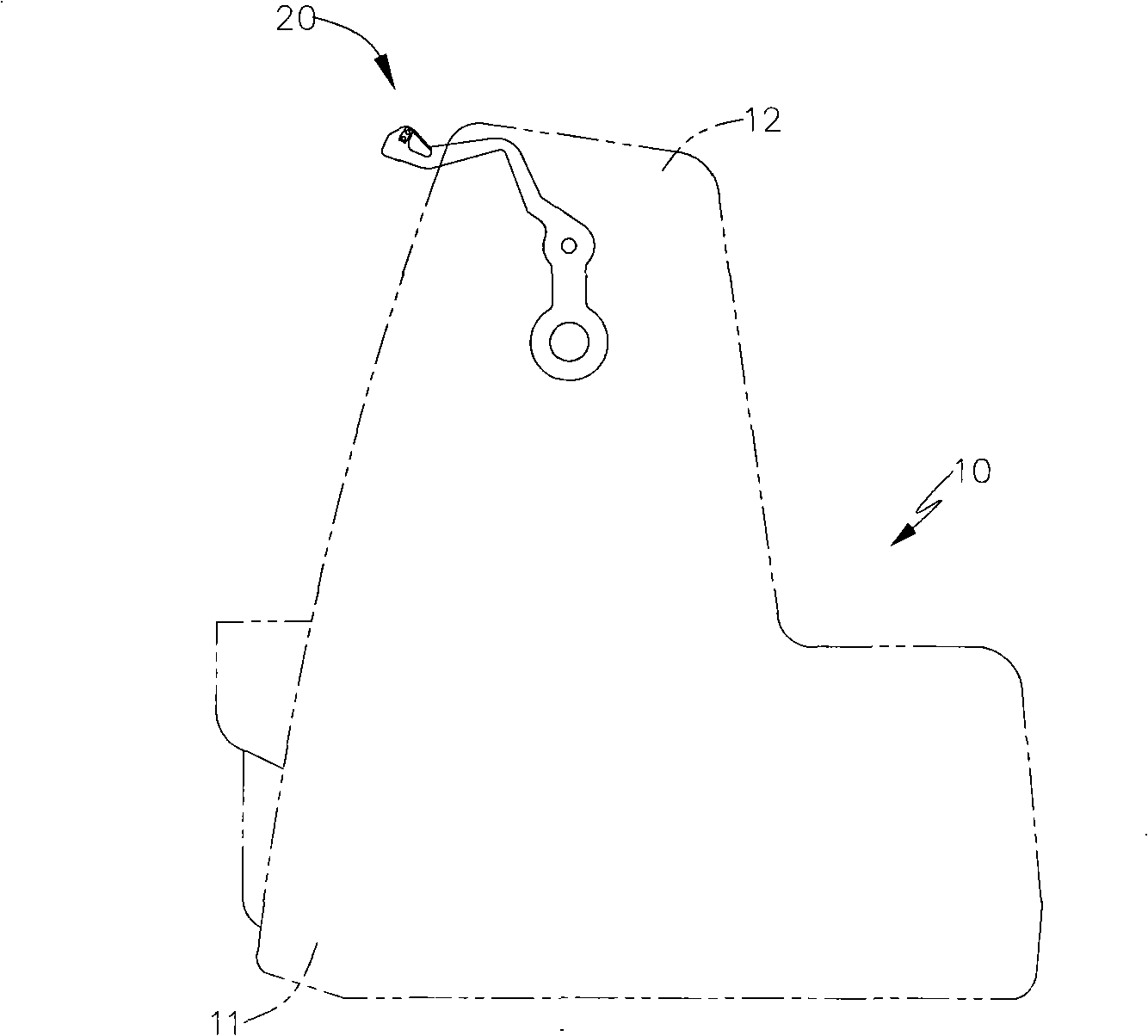

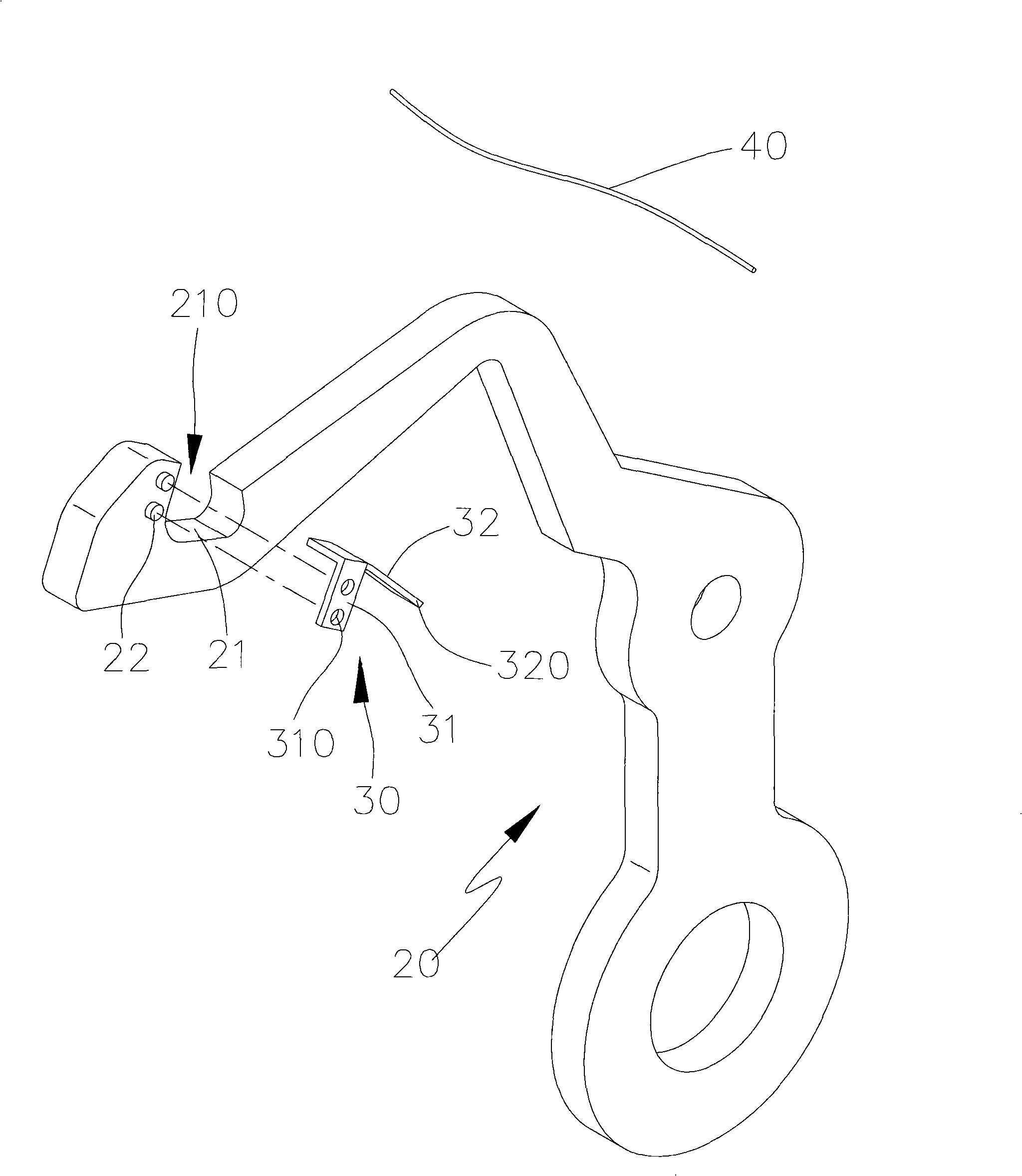

[0020] Such as figure 1 , 2 , 3, the sewing machine 10 has a machine base 11 and a cantilever 12, and a thread take-up lever 20 is additionally provided on the cantilever 12. The thread part 21 forms an open end 210 laterally, and the thread take-up lever 20 is provided with at least one positioning part 22 near the open end 210. One end of the member 30 is fixed, and the other end is bent to stop against the front of the opening end 210 of the wire holding portion 21, forming a one-way sealing structure.

[0021] The wire retaining member 30 mainly has a fixed end 31 flatly attached to the side of the thread take-up lever 20. The fixed end 31 is provided with a perforated fixed portion 310 relative to the positioning portion 22, and the fixed portion 310 is riveted through the positioning portion 22. In one body; and in the embodiment shown in the present invention, the number of the positioning part 22 and the fixing part 310 is a structural form that cooperates with each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com