Ultra-pure water membrane electrolyser

A membrane electrolysis and ultrapure water technology, applied in the field of electrolysis cells, can solve the problems of short service life of membrane electrodes, complex device structure, etc., and achieve the effects of low electrode polarization overpotential, small size and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

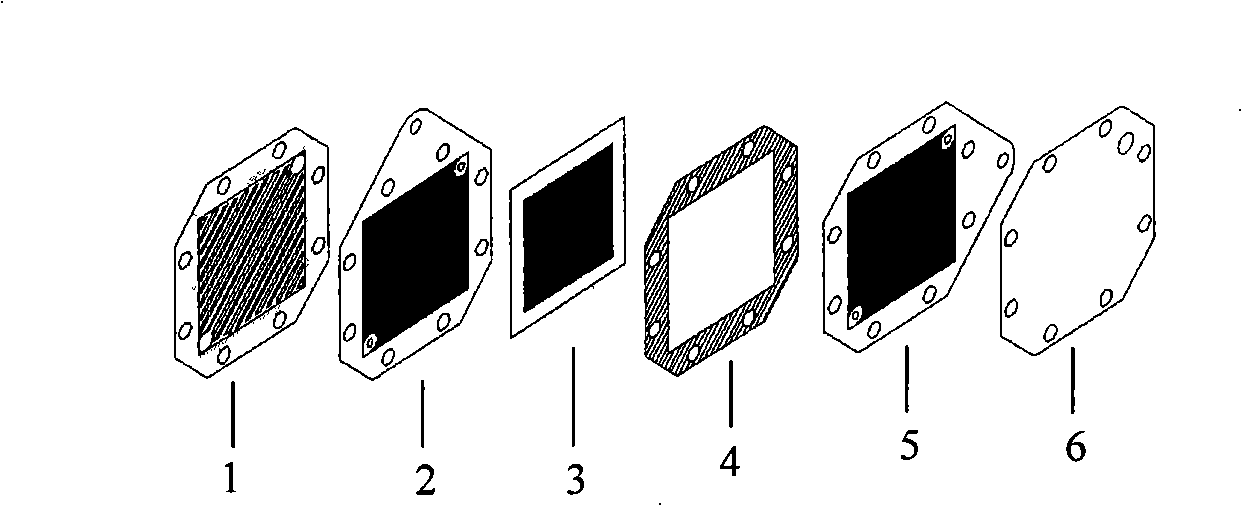

[0020] attached Figure 1-8 An embodiment of the present invention is collectively described. figure 1 It is a schematic diagram of the assembly of the components of the ultrapure water membrane electrolytic cell, in which, the anode splint 1, the anode current collector 2, the membrane electrode 3, the gasket 4, the cathode current collector 5, and the cathode splint 6 are stacked in the above order, Then tighten it with metal screws and nuts to form an ultrapure water membrane electrolytic cell.

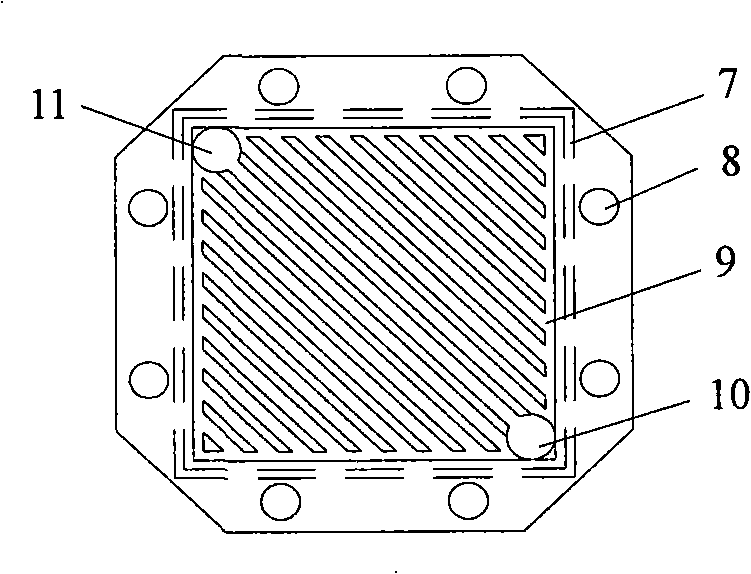

[0021] figure 2 It is the front structure diagram of the anode splint 1, there is a silicone rubber sealing ring in the sealing groove 7, which plays a role in preventing water and oxygen leakage; the fastening screw hole 8 plays the role of positioning and fixing; the parallel groove flow field 9 The flow channel is 1-1.5mm deep and 1-2mm wide, which can evenly distribute water to the reaction surface of the membrane electrode, where electrochemical anodic oxidation occurs, oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com