Method for refining acetylacetone

A technology of acetylacetone and refining method, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., which can solve the problems of not being able to obtain high-purity products, and achieve the effects of easy control, high product purity, and stable quality content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

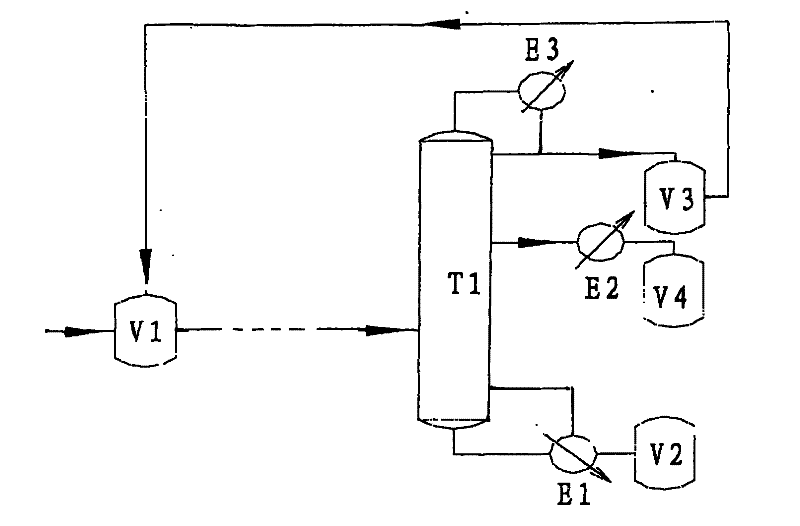

Image

Examples

Embodiment 1

[0024] The feed position is the 30th theoretical plate from the top of the tower, and the content of the crude acetylacetone component in the feed is the same as in Comparative Example 1.

[0025] Operating conditions of the refining tower: the pressure at the top of the tower is gauge pressure -63kPa, the reflux ratio is 5, the temperature at the top of the tower is 108°C, the temperature at the bottom of the tower is 125°C, and the temperature of the side line of acetylacetone is 110°C.

[0026] Rectification result: the extraction position of acetylacetone is the 10th theoretical plate counted from the top of the column from the side line of the refining column T1, and the product purity is 99.9%.

Embodiment 2

[0028] Due to fluctuations in the working conditions of the previous section, the isopropenyl acetate in the feed enters the refining tower T1, and the feed position is the 35th theoretical plate from the top of the tower. The composition of the crude acetylacetone of the feed is: 97.7% acetylacetone, 0.3% acetone, 1% isopropenyl acetate, 1% high boiling components.

[0029] The operating conditions of the refining tower T1 are: the pressure at the top of the tower is gauge pressure -86kPa, the reflux ratio is 5, the temperature at the top of the tower is 75°C, the temperature at the bottom of the tower is 104°C, and the temperature of the side line of acetylacetone is 86°C.

[0030] Acetylacetone is withdrawn from the side line of the refining tower T1, and its position is the 15th theoretical plate from the top of the tower. The rectification result: the product purity is 99.9%.

Embodiment 3

[0032] The feed position is the 32nd theoretical plate from the top of the tower. Since acetylacetone decomposes into acetone and other low-boiling components and enters the refining tower T1, the composition of the feed crude acetylacetone is: 97.7% acetylacetone, 1% acetone , 0.3% isopropenyl acetate, 1% high boiling components.

[0033] The operating conditions of the refining tower T1 are: the pressure at the top of the tower is -45kPa, the reflux ratio is 8, the temperature at the top of the tower is 113°C, the temperature at the bottom of the tower is 129°C, and the temperature of the side line of acetylacetone is 117°C.

[0034] Acetylacetone is withdrawn from the side line of the refining tower T1, and its position is the ninth theoretical plate from the top of the tower. The rectification result: the product has a purity of 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com