Self-unloading floating head isothermal reaction methanol synthesis reactor

A methanol synthesis tower and isothermal reaction technology, applied in the field of machinery, can solve the problems of unloading materials, reducing energy saving effects, and high manufacturing costs, and achieve the effects of reducing equipment diameter, reducing equipment cost, and saving precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

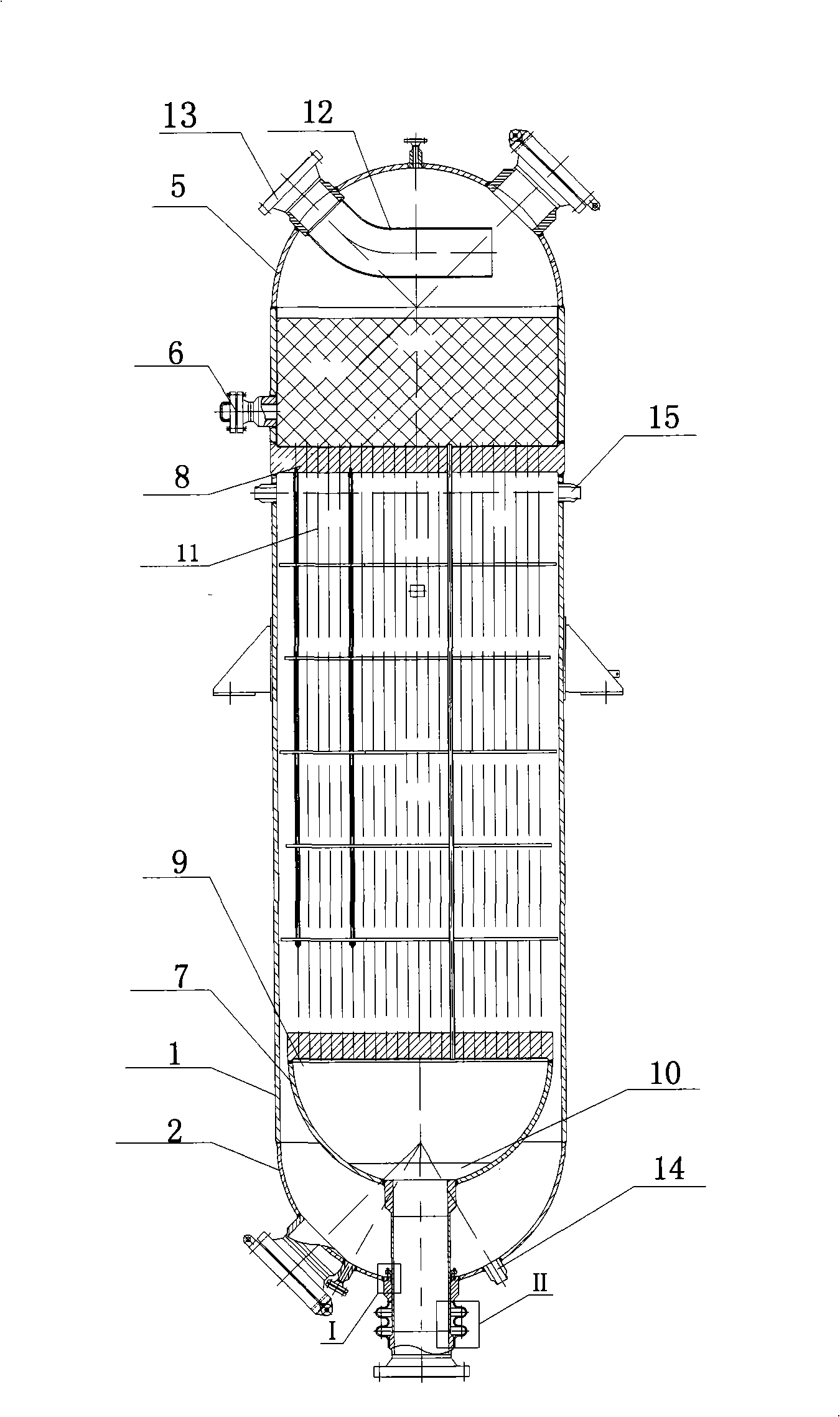

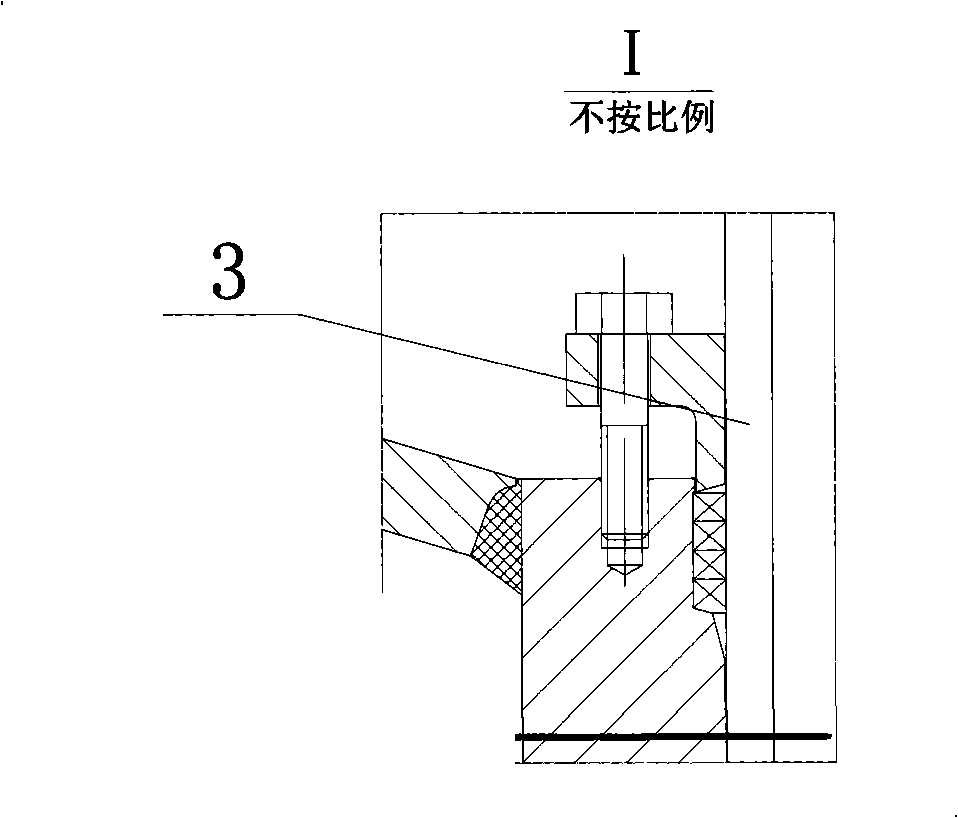

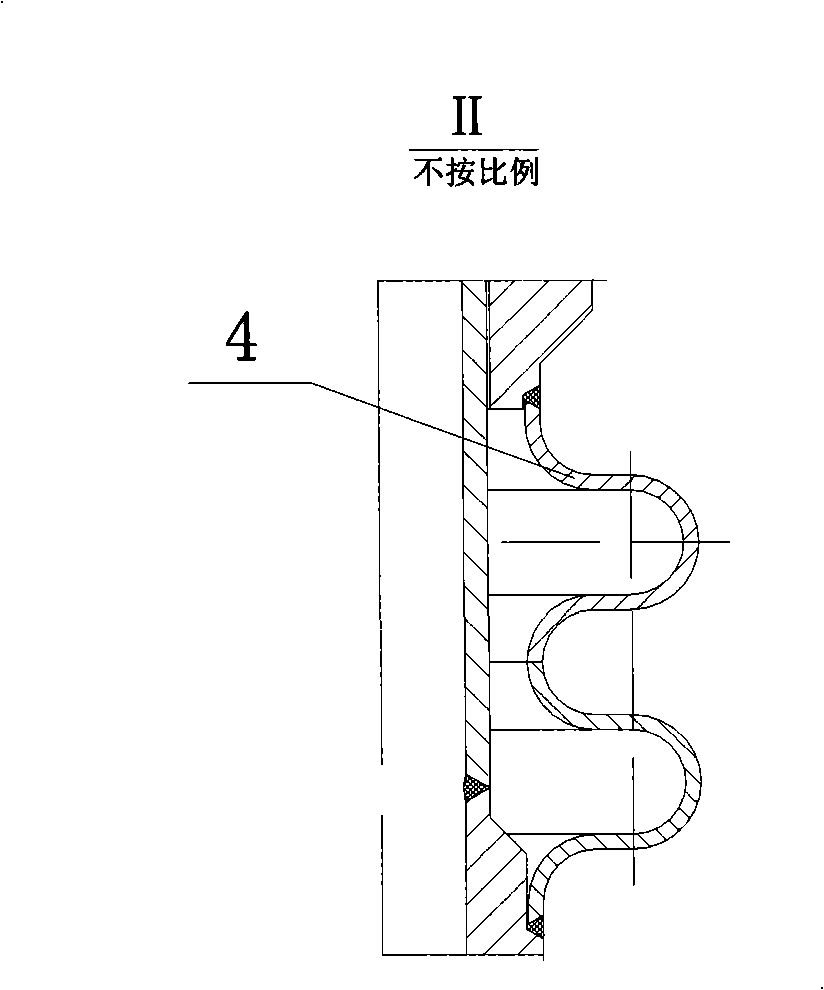

[0024] like figure 1 As shown, the self-unloading floating head isothermal reaction methanol synthesis tower of the present invention mainly includes a low-pressure outer shell 1, a lower head 2 of the outer shell, a high-temperature gas outlet pipe 3, a high-pressure upper pipe box 5, a high-pressure inner head 7, and an upper pipe Plate 8, lower tube plate 9, reaction tube 11 with catalyst inside, gas distributor 12 and gas inlet pipe 13, wherein high pressure upper tube box 5, low pressure outer shell 1 and outer shell lower head 2 are welded as a whole, The gas inlet pipe 13 passes through the high-pressure upper pipe box 5 and enters its interior, and a gas distributor 12 is installed at the end of the gas inlet pipe 13. The tube plate 8 is fixedly connected with the low-pressure outer shell 1 , and the lower tube plate 9 and the low-pressure outer shell 1 are in clearance fit. A plurality of reaction tubes 11 are installed between the upper tube sheet 8 and the lower tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com