Stable adhesives from urea-denatured soy flour

A technology of soybean flour and adhesives, which is applied in adhesive types, protein adhesives, adhesives, etc., can solve the problems of lack of hydrolytic stability of the polymer skeleton, and achieve high tolerance, excellent biological resistance, Effects that are easy to transfer and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

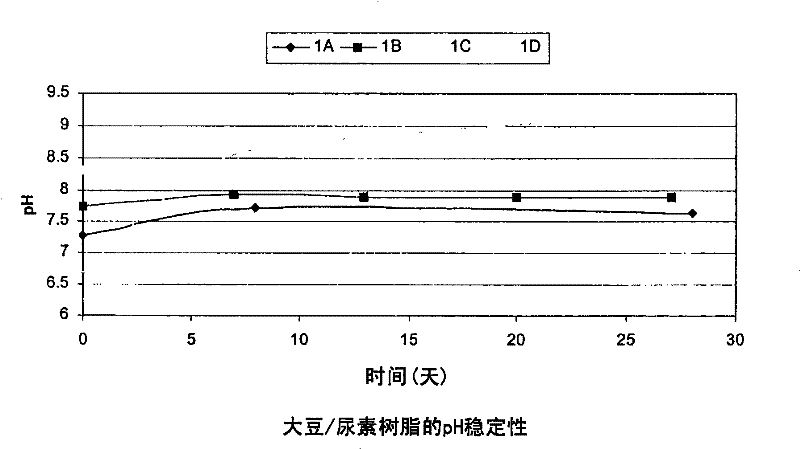

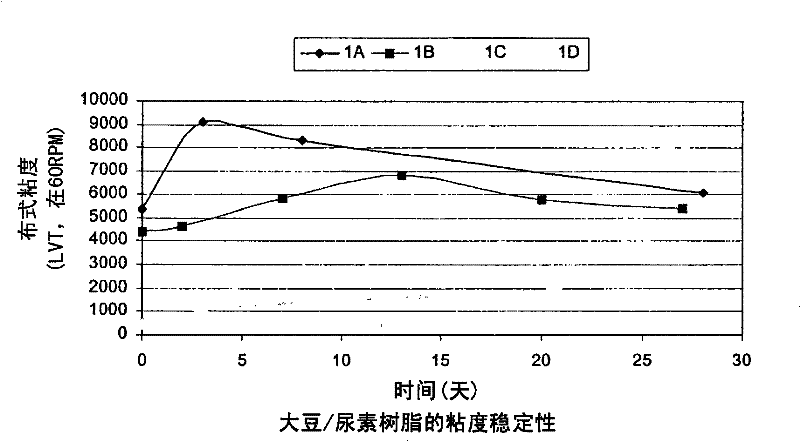

[0090] Soy flour is heat denatured and then reacted with urea to produce a stable soy / urea aqueous product (SUP). The method of embodiment 1A and 1C is identical, and difference is only the consumption of various raw materials. Example 1D is similar to 1B except that the temperature used is different (D-50°C, B-90°C), and Example D also uses low urease roasted soybeans (CG4).

[0091] Preparation method: Add water to a three-neck round bottom flask equipped with a heating mantle, temperature controller, reflux condenser and mechanical stirrer. Soy flour was added to the water over a period of 2-5 minutes at room temperature. The mixture was stirred for 5 minutes until homogeneous and then heated to 90° C. over 5-30 minutes. While stirring, the reaction was held at 90°C ± 2°C for 1 hour at which time urea was added to the urease-free soybeans and the reaction was reheated to 90°C and held at 90°C ± 2°C for 1 hour while stirring. The reaction was cooled to 25°C on an ice / wate...

Embodiment 2

[0107] Embodiment 2: comparative example

[0108] Some recent work has demonstrated the known dry and wet adhesive strengths of non-crosslinked soy protein isolates. A comparison of these binders with the binders of the present invention shows that improvements can be achieved with low cost, high sugar content soy flour.

[0109] Example 2A is a low temperature urea-denatured product prepared as described by Sun, except using 23.9% solids instead of 14.0%. In addition, Sun's product was lyophilized and the product of the present invention was used directly.

[0110] Preparation method: Add water and urea to a three-neck round bottom flask equipped with a heating mantle, temperature controller, reflux condenser and mechanical stirrer. The solution was heated to 25°C, at which point SPI was added over a period of 15 minutes. While stirring, the mixture was maintained at 25°C ± 2°C for 1 hour. The reaction product was then stored at room temperature until use.

[0111] t...

Embodiment 3

[0129] Preparation method: The product prepared according to the method shown in 1B was added to a three-neck round bottom flask equipped with a mechanical stirrer. Add 50% H at room temperature while stirring 2 SO 4 to lower the pH. After the acid addition, the solution was stirred for 15 minutes and then stored at room temperature until use.

[0130] Example 3A was placed in a beaker and the required amount of PAE was added while stirring. Examples 3B and 3C were prepared using the same method. These samples were stirred vigorously for 1 minute until homogeneous and then stored at room temperature until use.

[0131] Table 8

[0132] Formulation of Example 3A (pH 4.5, 0% PAE)

[0133] order

Element

amount (g)

Soy / urea

percentage of

01

similar to example

1B

200.0

60.0

02

50%H 2 SO 4

2.8

1.4

2.3

Total

202.8

61.4

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com