Coal quality on-line detecting analytical method based on regression analysis

A regression analysis and analysis method technology, applied in material excitation analysis, fluorescence/phosphorescence, etc., can solve problems such as insufficient precision, large investment, and inability to achieve full element analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

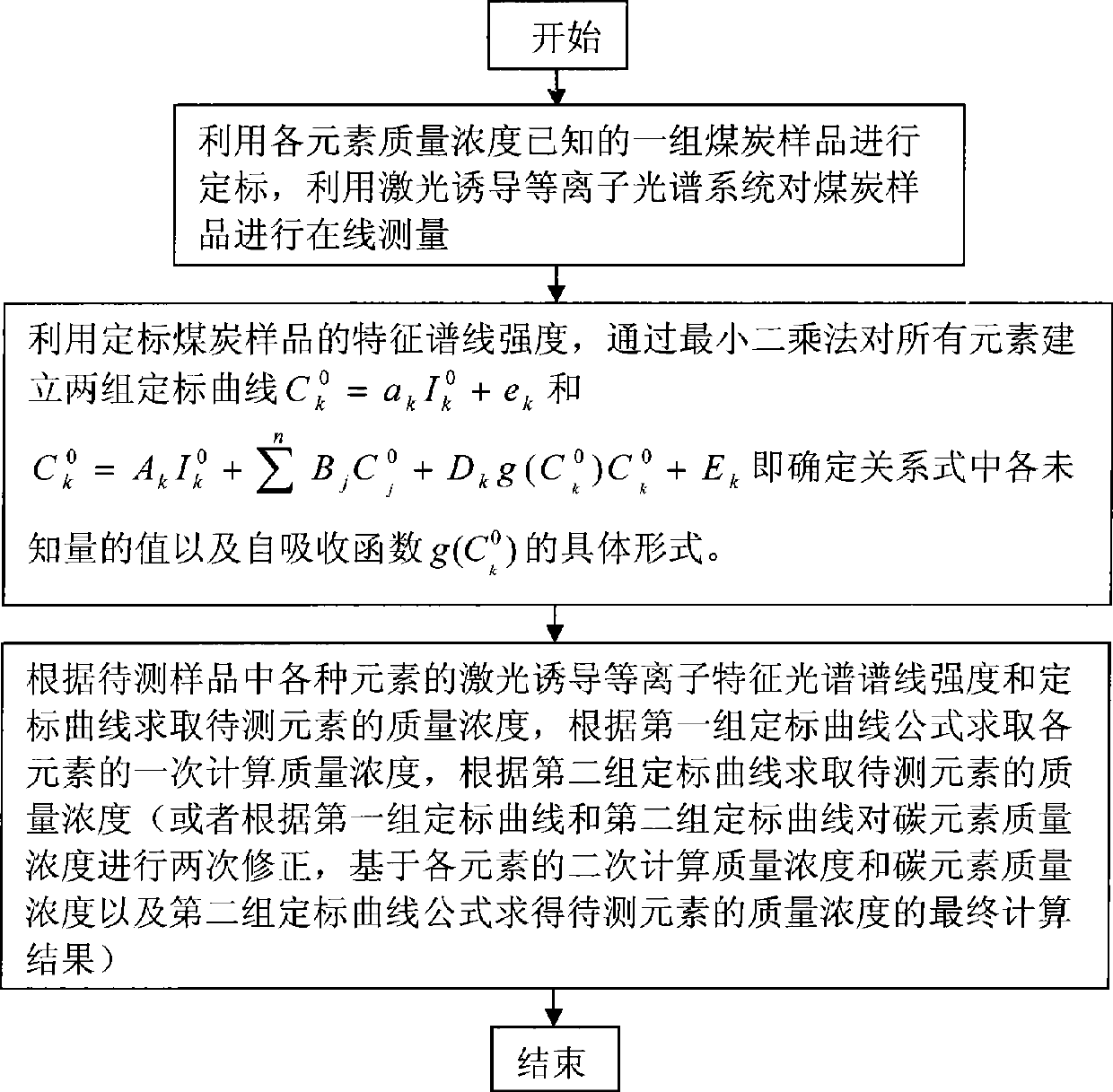

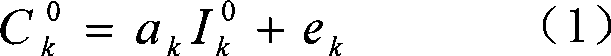

[0076] A method for online detection and analysis of coal quality based on regression analysis, characterized in that

[0077] 1) First, a group of anthracite coal samples with known mass concentrations of each element are used for calibration. The mass concentrations of the main elements of the coal samples are sample 1 containing 92.27% of C, 1.14% of H, 4.72% of O, and 0.88% of N. S 0.54%; Sample 2 contains C 95.76%, H 1.16%, O 2.37%, N 0.88%, S 0.32%; Sample 3 contains C 94.90%, H 1.18%, O 2.55%, N 0.72%, S 0.65% ;Sample 4: C 91.59%, H 4.04%, O 2.59%, N 1.46%, S 0.32%, because the mass concentration of trace elements is very small, for the convenience of explanation, the influence of trace elements on the signals of the measured elements is not considered here , of course, trace elements can also be considered according to actual measurement needs. Put five kinds of coal samples on the coal conveyor belt in turn, and use the laser-induced plasma spectroscopy system instal...

Embodiment 2

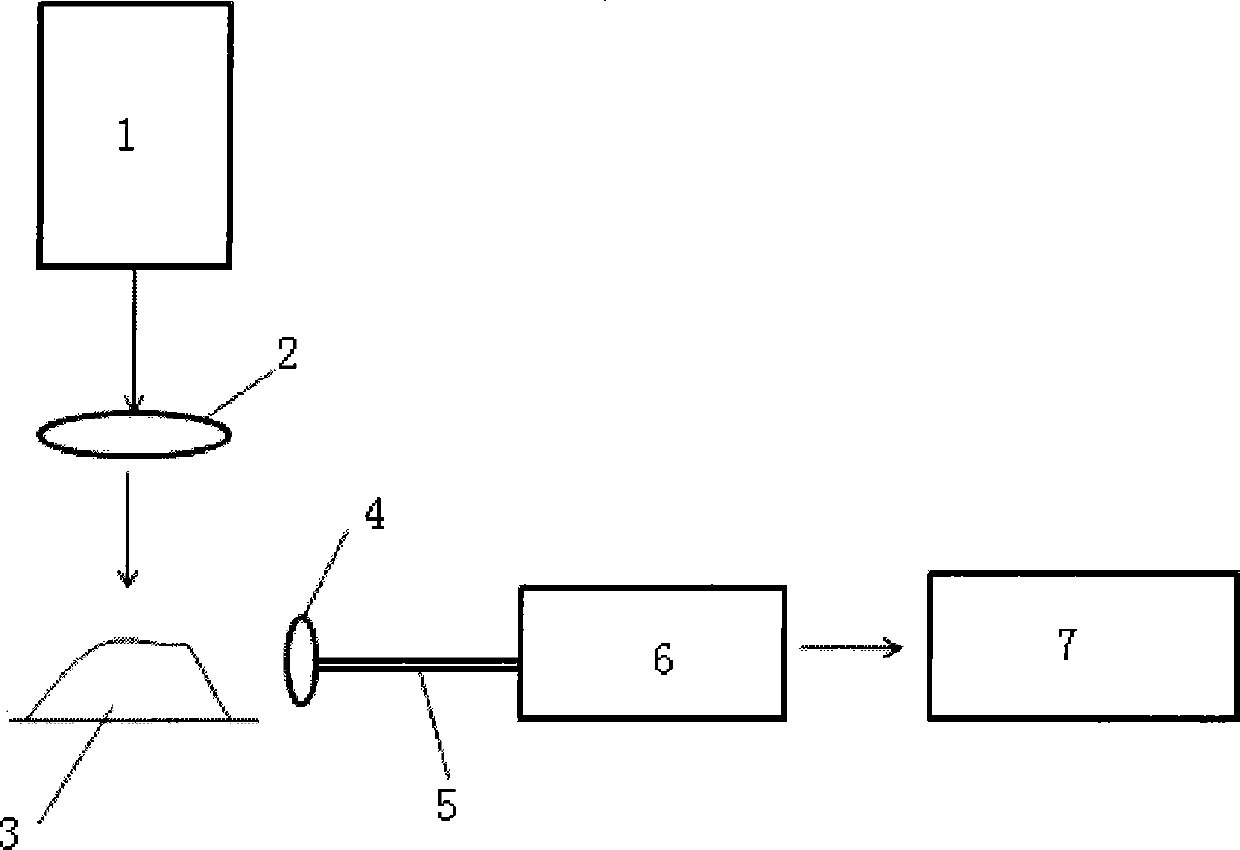

[0099] 1) First, a group of anthracite coal samples with known mass concentrations of each element are used for calibration. The mass concentrations of the main elements of the coal samples are sample 1 containing 92.27% of C, 1.14% of H, 4.72% of O, and 0.88% of N. S 0.54%; Sample 2 contains C 95.76%, H 1.16%, O 2.37%, N 0.88%, S 0.32%; Sample 3 contains C 94.90%, H 1.18%, O 2.55%, N 0.72%, S 0.65% ;Sample 4: C 91.59%, H 4.04%, O 2.59%, N 1.46%, S 0.32%, because the mass concentration of trace elements is very small, for the convenience of explanation, the influence of trace elements on the signals of the measured elements is not considered here , of course, trace elements can also be considered according to actual measurement needs. Put five kinds of coal samples on the coal conveyor belt in turn, and use the laser-induced plasma spectroscopy system installed on the coal conveyor belt to detect the coal samples online, such as figure 1 As shown: the pulsed laser 1 is used a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com