Bottom assembling electromagnetic agitator for direct current excitation smelting furnace

An electromagnetic stirrer, direct current technology, applied in stirring devices, furnaces, furnace components, etc., can solve the problems of high cost, high cost of permanent magnetic stirrers, volatile magnetic force, etc., and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

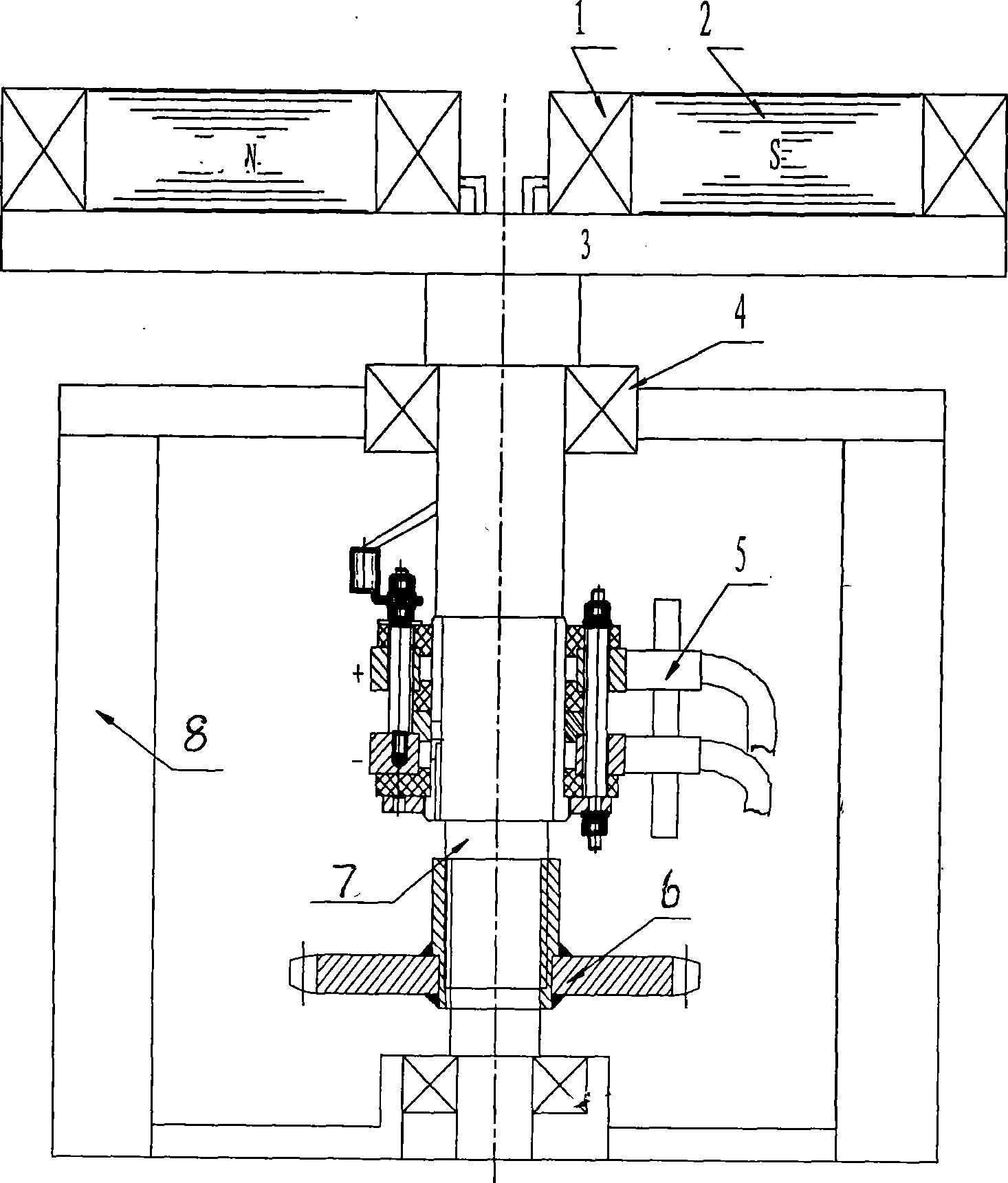

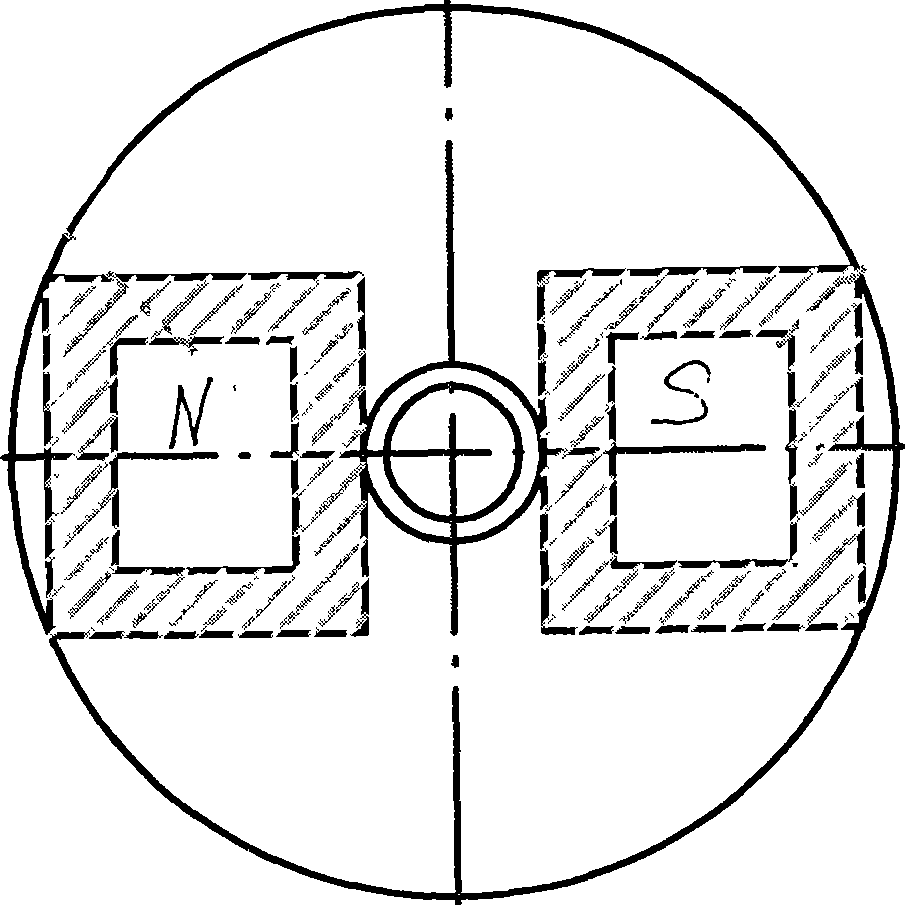

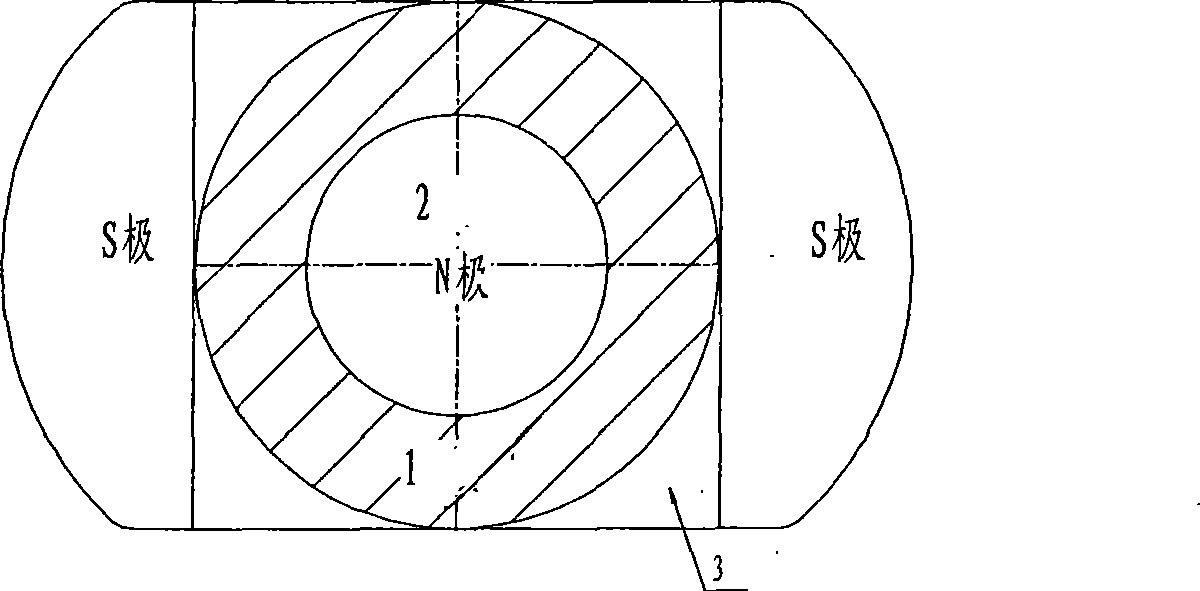

[0041] Such as figure 1 , figure 2 As shown, the present invention is composed of a coil 1, an iron core 2, a yoke 3, a bearing 4, a slip ring 5, a transmission wheel 6, a main shaft 7, a bracket 8, a rectification system and a drag system, wherein the rectification system is connected to the slip ring , the drag system is connected to the transmission wheel, which is not shown in the figure.

[0042] The coil and the iron core are two groups, which are installed on the plane of the circular mounting plate, that is, the yoke iron 3 . The plane of the yoke and the main shaft are installed perpendicular to each other. The main shaft is installed on the bracket 8 through a set of bearings, the collector ring is installed in the middle of the main shaft, the positive and negative poles of the rectified power supply of the rectification system are connected to the collector ring 5, and the two excitation coils of the agitator are connected to the collector ring through wires. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com