Residential structure of multi-layer cold-formed section steel assembled house

A technology of combining houses and section steel, applied in the direction of building structure, construction, etc., can solve the problems of reducing structural rigidity and bearing capacity, unable to meet the requirements of strength and stability, structural lateral rigidity and strength, etc. The effect of self-weight, strengthening vertical continuity, and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

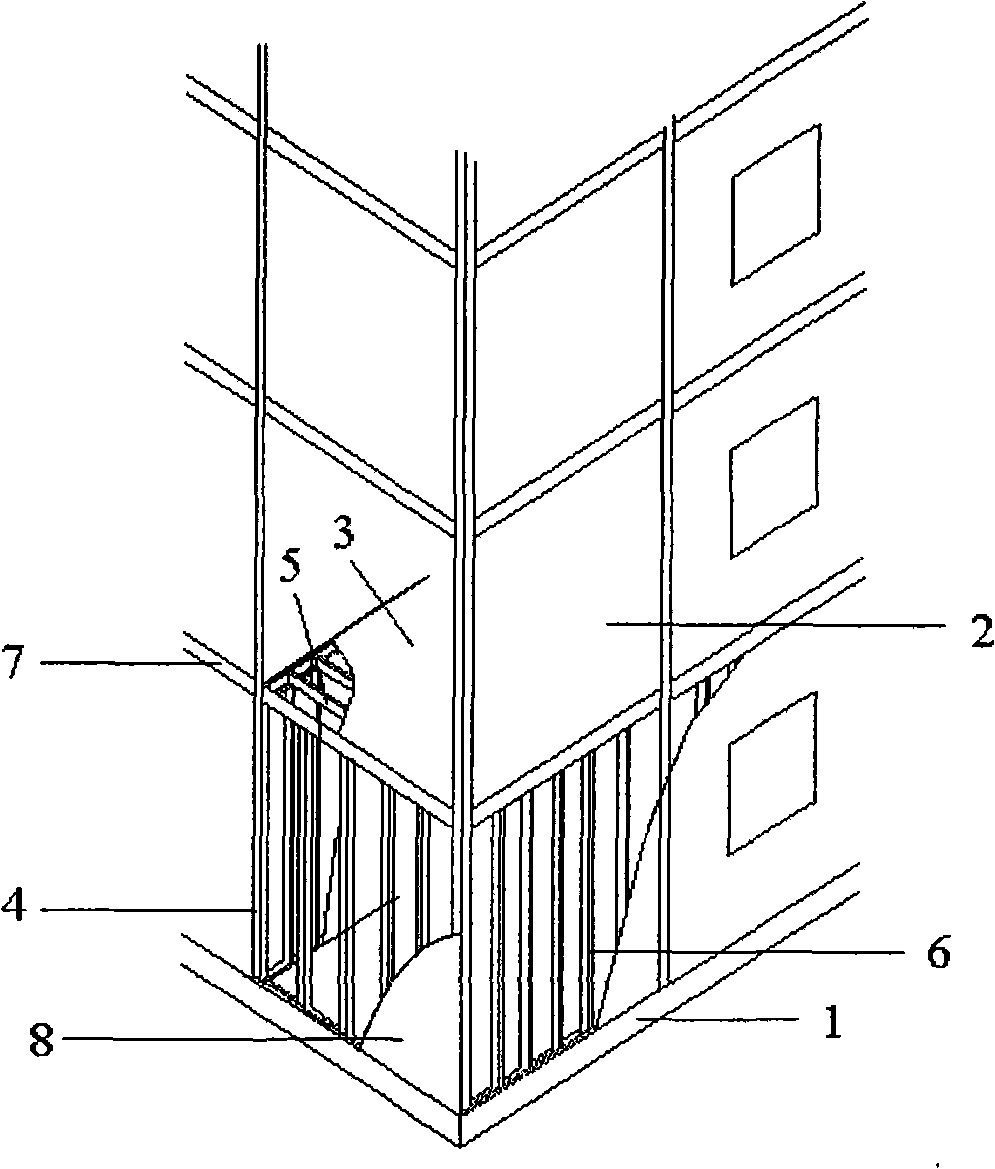

[0047] see Figure 1 to Figure 20 , a multi-storey cold-formed steel composite house residential structure, which includes a foundation 1, a number of wall units 2 on the foundation 1, a roof unit 3, square pipe columns 4 vertically fixed at both ends of the wall units and respectively connected The joist guide rail 15 of the wall unit 2 and the roof unit 3, wherein the roof unit 3 includes a flat plate portion 17 and a joist 5 embedded in the flat plate portion 17, the material of the flat plate portion 17 is a lightweight building board, and the wall The unit 2 is provided with a reinforced section column 6 that bears the load of the joist 5 of the roof unit 3, and the reinforced section column 6 can adopt reinforced section forms such as a double C-shaped section 24 or a Σ-shaped section 25 connected with self-tapping screws 11 . In addition, the residential structure of the multi-storey cold-formed steel composite house also includes outer frame beams 7 arranged around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com