Highly-permanent connection mode for prefabricated pier body and cushion cap of cross-sea bridge

A technology of sea-crossing bridges and connection methods, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as affecting the appearance quality and reducing the service life of structures, and achieve the effect of prolonging the service life and improving the durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

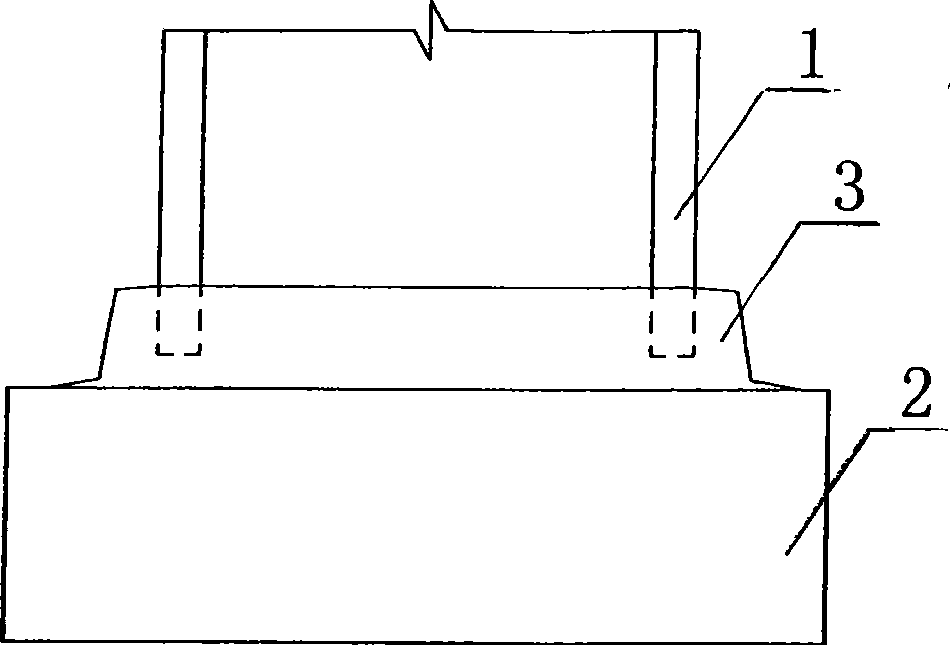

[0014] refer to figure 1 , the prefabricated pier body 1 and cap 2 of the present invention are connected with the wet joint concrete 3 in the middle. Wet joint concrete 3 adopts high durability marine concrete,

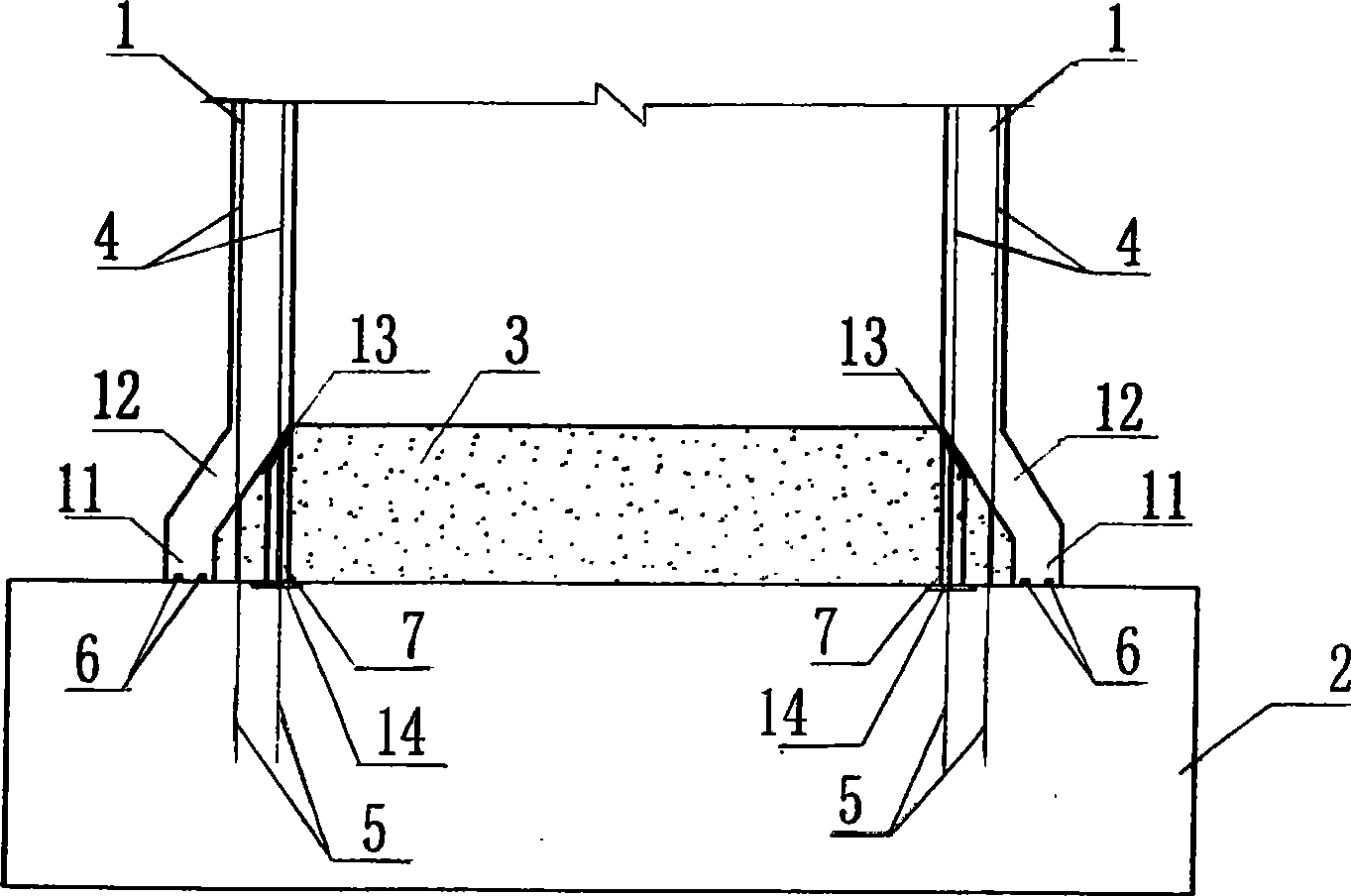

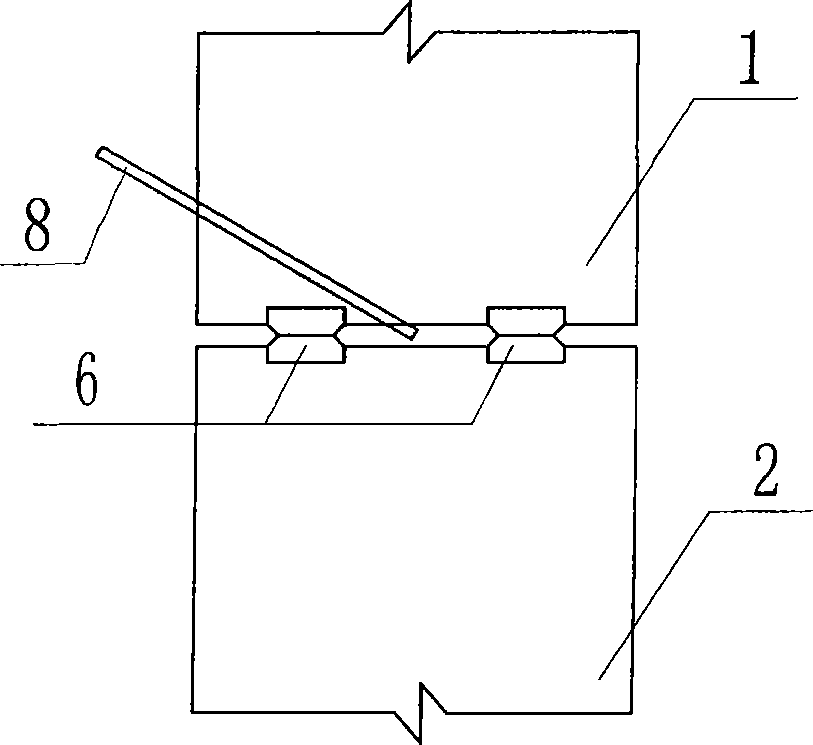

[0015] refer to figure 2 , the lower part of the prefabricated pier body 1 is the flared transition section 12+straight section 11. The height of the flared gradient section 12 at the lower part of the prefabricated pier body 1 is ≥75cm, and the height of the straight section 11 is ≥50cm; the reserved steel bars 4 of the prefabricated pier body 1 and the reserved steel bars 5 of the cap 2 are connected by double-sided welding; the prefabricated pier body Two water-stop rubber strips 6 are buried between 1 and cap 2, and epoxy mortar is poured between the two water-stop rubber strips.

[0016] During the construction of the present invention, the inner side of the flared transition section at the lower part of the prefabricated pier body is provided with profiled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com