Overlap beams downstriker movable mould frame bridging machine

A technology of moving formwork and bridge building machine, which is applied in bridges, bridge construction, building construction, etc., can solve the problems of difficult connection between comb-shaped beams and movable doors, high force requirements for movable doors, and long construction assistance time. , to achieve the effect of reducing equipment weight and equipment cost, improving beam-making efficiency and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

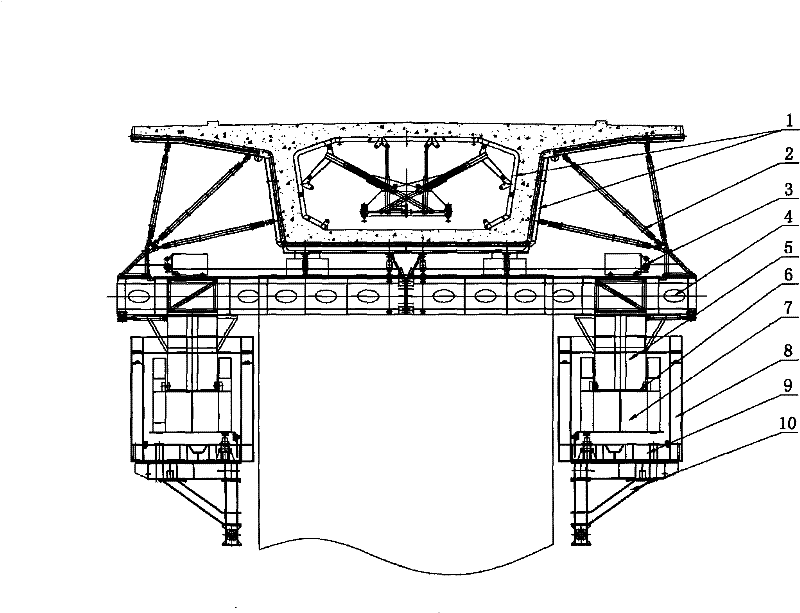

[0020] The bridge building machine of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] see Attachment

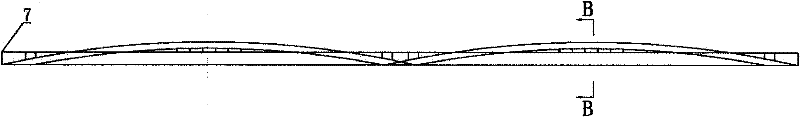

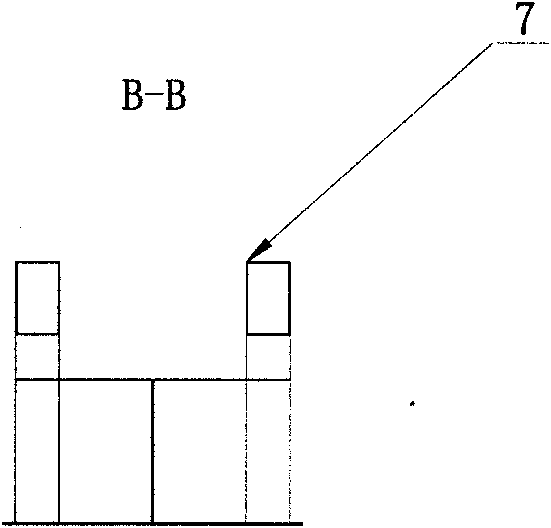

[0022] The bridge building machine is composed of main girder 5, guide beam 7, comb-shaped formwork beam 4, pier side bracket 10, trolley 9, counterweight trolley 3, hydraulic system, formwork system, etc. The bridge building machine has a symmetrical structure. There are four cars 9, two main girders 5 and two guide beams 7, eight pairs of comb-shaped beams 4, trolley 9 is arranged on the top of the bracket 10 next to the pier, and the guide beam 7 is arranged on the top of the trolley 9. 9 and the guide beam 7 is provided with a hydraulic cylinder 8, the lower end of the hydraulic cylinder 8 is fixed on the trolley 9, and the upper end is located below the load-bearing ears 12 arranged on both sides of the main beam 5, and the hydraulic cylinder 8 serves to adjust the position of the guide beam 7 , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com