Double-open ring control device and method applied to self-regulating technology

An autoleveling and control device technology, applied in the field of cotton textile devices and double open-loop control devices, can solve problems such as advance leveling, high requirements for testing equipment, and system malfunctions, so as to ensure uniformity, improve anti-interference performance, The effect of eliminating blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

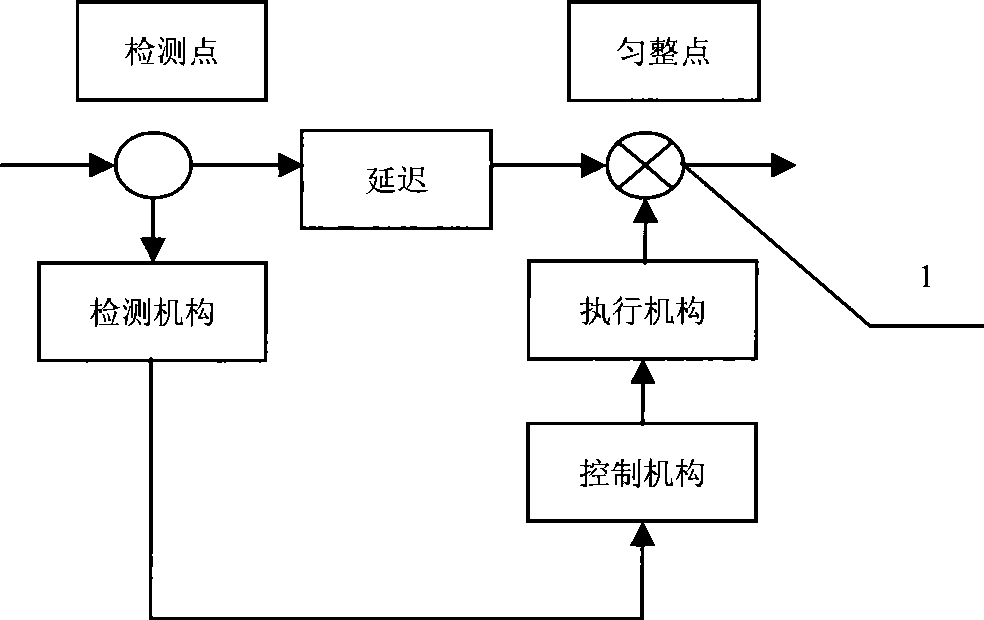

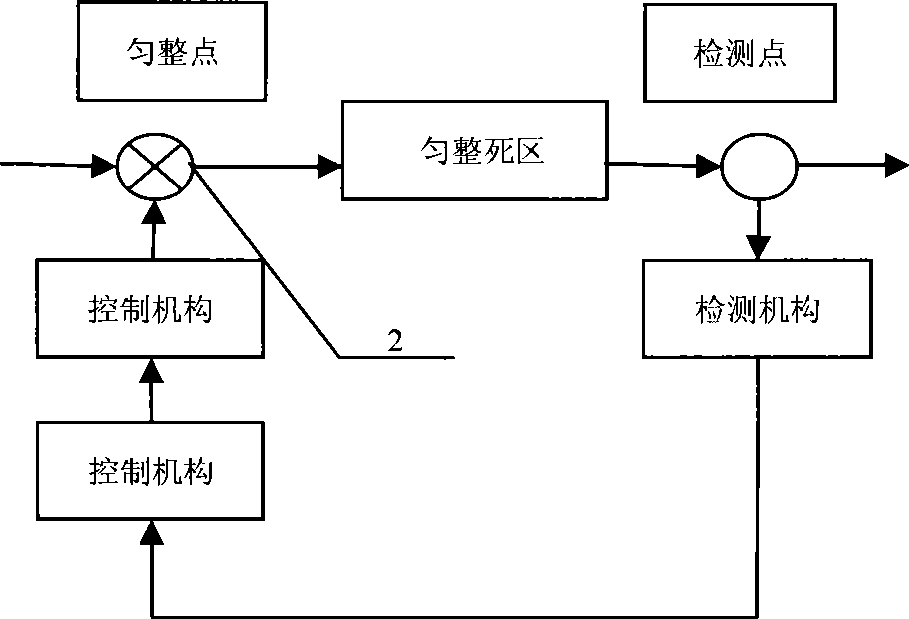

[0040] Such as Figure 4 As shown, it is a structural block diagram of a double open-loop control device applied to autoleveling technology provided by the present invention, including a rear roller 4, a middle roller group 5 is arranged in front of the rear roller 4, and a middle roller group 5 is arranged in front of the middle roller group 5. There is a front roller 6, a first detection mechanism is arranged behind the rear roller 4, the rear roller 4 and the front roller 6 are respectively connected with the first actuator and the second actuator, and a second detection mechanism is arranged between the middle roller group 5 mechanism, the output ends of the first detection mechanism and the second detection mechanism are connected to the input end of the control mechanism, and the output ends of the control mechanism are respectively connected to the input ends of the first actuator and the second actuator. The middle roller group 5 is composed of two pairs of rollers 7, ...

Embodiment 2

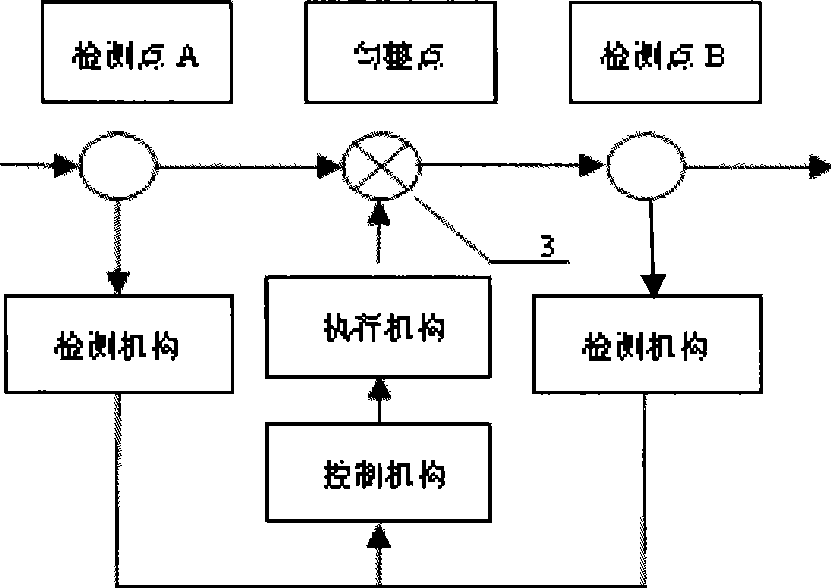

[0061] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the control mechanism is divided into a first control mechanism and a second control mechanism, the output end of the first detection mechanism is connected to the input end of the first control mechanism, and the first control mechanism The output end of the second detection mechanism is connected to the input end of the first actuator, the output end of the second detection mechanism is respectively connected to the input ends of the first control mechanism and the second control mechanism, and the output end of the second control mechanism is connected to the input of the second actuator end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com