Construction method for internal cooling wall and furnace liner of blast furnace

A construction method and stave technology, applied in the direction of cooling devices, internal forms, etc., can solve the problems of not meeting the requirements of engineering practice, not being able to effectively use transportation channels, and increasing costs, so as to shorten the construction period, shorten the comprehensive construction period, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

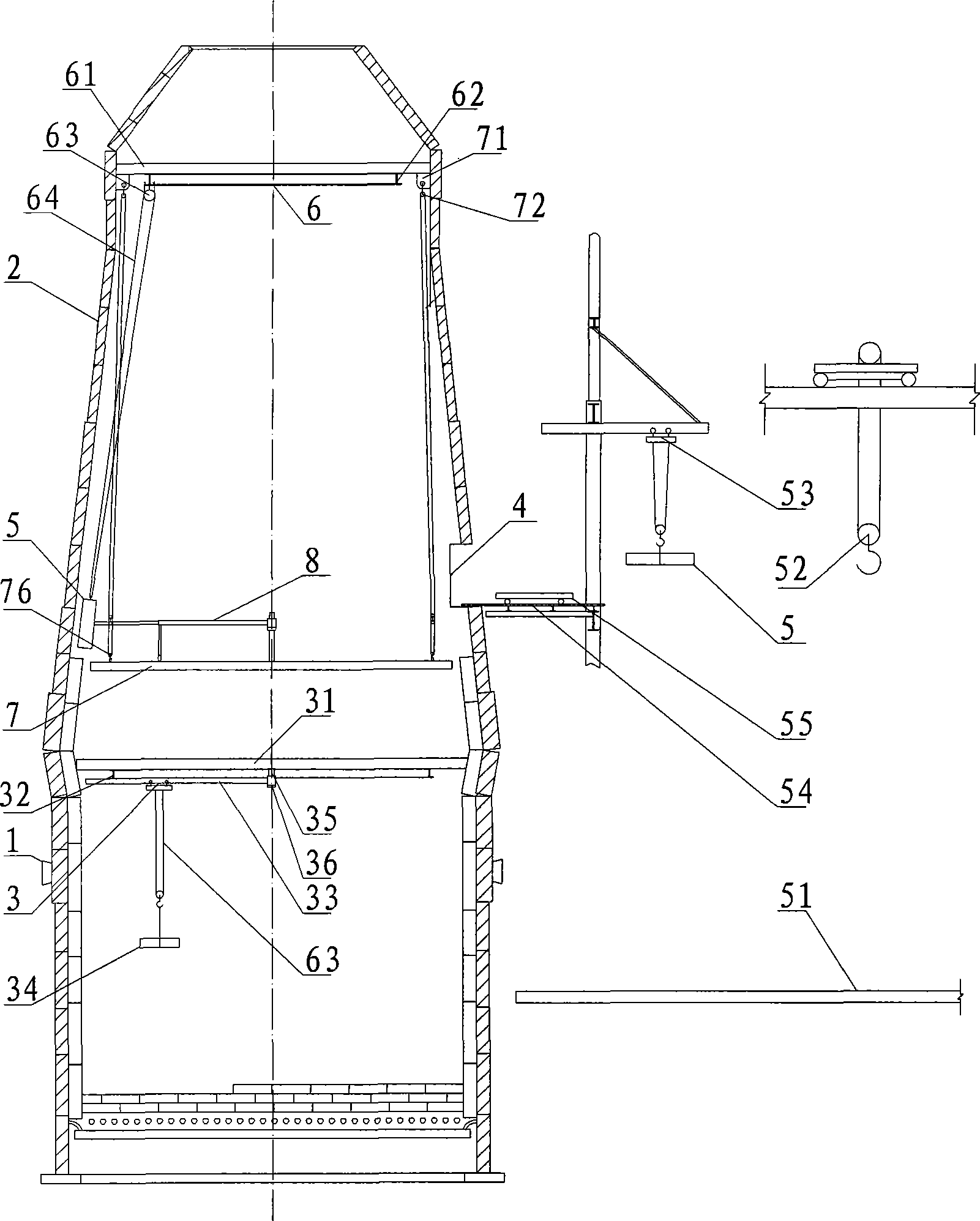

[0046] Such as Figure 1 to Figure 7 As shown, a blast furnace has a height of 40.4m (the furnace shell is a self-supporting variable-section rotating steel shell), and the on-line intermediate repair project for the blast furnace body is carried out. This project requires that the blast furnace shell 2 above the tuyere 1 be removed and updated. Stave 5 and furnace lining 34 are all dismantled and replaced, and stave 5 in the furnace altogether 16 bands (about 980t), adopt construction method of the present invention to install its stave 5 and furnace lining 34, its technological process is as follows figure 1 As shown, it specifically includes the following steps:

[0047] (1) Install furnace shell and cooling stave hoisting device: first, use a tower crane to hoist the blast furnace shell 2 from the tuyere 1 from bottom to top, and after hoisting the blast furnace straight section furnace shell 2, place the lining lifting device 3, Bosh protection shed 31 (furnace lining li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com