Oxygen functionalized carbon material and use thereof

A technology of functional grouping and carbon materials, applied in the direction of catalyst carriers, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor repeatability of carbon material products, differences in performance of adsorbents and catalysts, etc., and achieve short preparation cycle, Increased adsorption capacity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

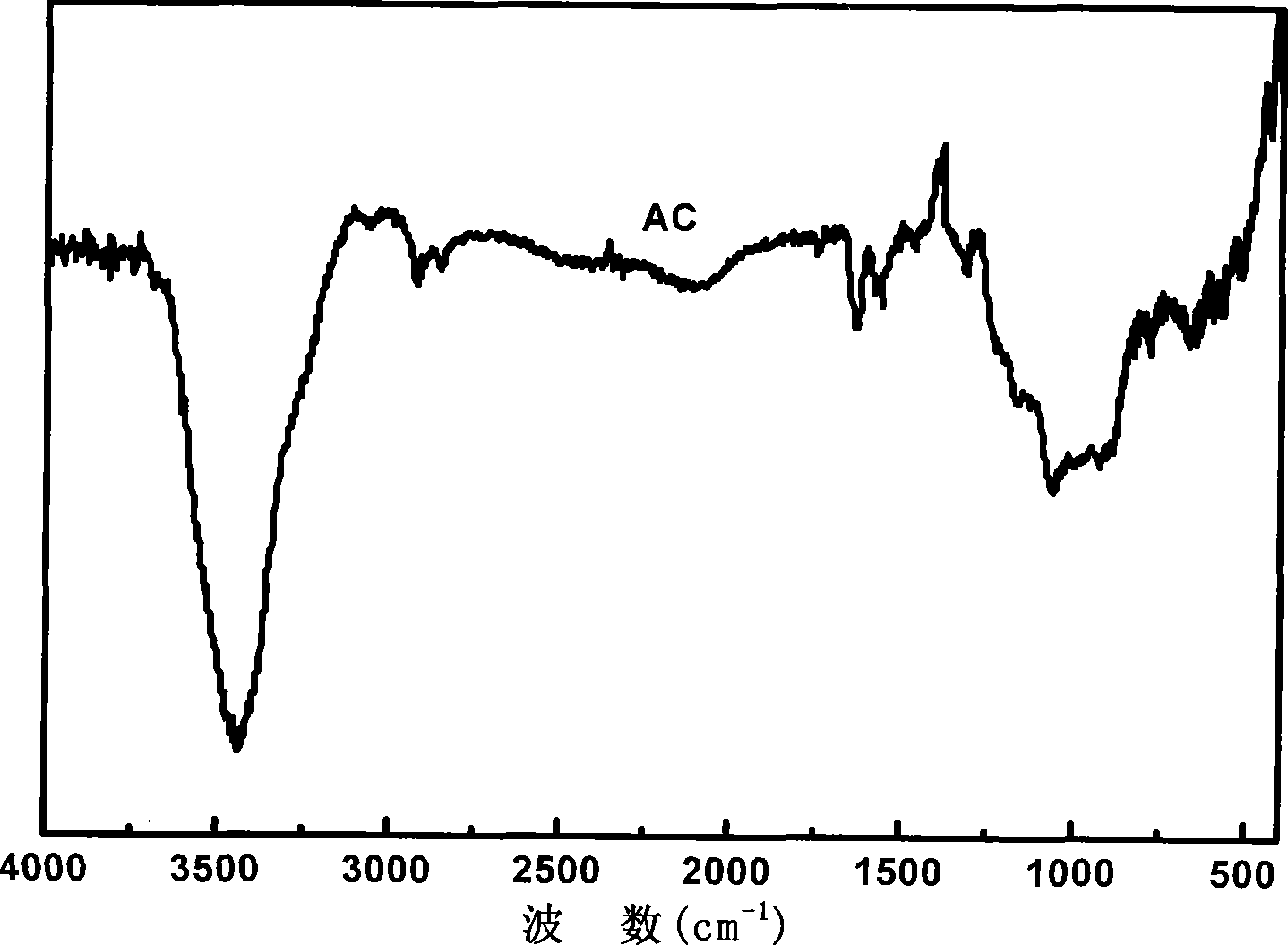

[0017] Weigh 200 grams of carbon material and put it into the reactor, then add 1000 grams of 5%, 10%, 15% and 30% hydrogen peroxide solution, place it in a constant temperature water bath at 80 ° C for 5 hours, then filter and wash , and dried to obtain a surface-modified carbon material. Depend on figure 1 It can be seen that in the infrared spectrogram of the raw material activated carbon, except at 3450cm -1 The left and right can be attributed to the surface phenolic hydroxyl group or outside the peaks of adsorbed water, at 2955 and 2885cm -1 The spectrum peaks can be attributed to the C-H vibration peaks, there is no or very weak carboxyl peak near 1700, and the 1660cm -1 Spectrum peak greater than 1550cm -1 Spectral peaks, implying its poor hydrophilicity and lack of basic sites. figure 2 The infrared spectra of activated carbon after oxidative modification with different concentrations of hydrogen peroxide for 5 hours are given. It can be seen from the figure tha...

Embodiment 2

[0020] Weigh 200 grams of raw carbon material and put it into a reactor, then add 5% hydrogen peroxide solution with a concentration of 1000 grams, place it in a constant temperature water bath at 80 ° C for reflux treatment for 2, 3.5 and 5 hours, then filter, wash, and dry to obtain Surface-modified carbon materials. Depend on image 3 It can be seen that with the prolongation of hydrogen peroxide treatment time, at 2955 and 2885cm -1 The peak of the spectrum is attributed to the disappearance of the peak of the C-H vibration, and at the same time at 1275cm -1 The C-O stretching vibration peak is more obvious. The results showed that the structure of oxygen-containing functional groups on the surface increased significantly after oxidation treatment.

[0021] The texture parameters of modified samples and raw carbon materials treated with hydrogen peroxide for different times were characterized by nitrogen adsorption, and the results are shown in Table 1. It can be seen ...

Embodiment 3

[0026] Weigh 10 grams of raw carbon material and put it into a reactor, then add 5% hydrogen peroxide solution with a concentration of 100 grams, place it in an ultrasonic generator (60W, 20KHz) for 0.5h, filter, wash, and dry to obtain a surface-modified The carbon material is detected by infrared spectroscopy, and it is found that the oxygen-containing functional groups on the surface of the carbon material increase. And the results of X-ray diffraction showed that the amorphous structure of activated carbon was basically unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com