Temperature calibration system and method

A technology of calibration system and calibration method, which is applied in the direction of temperature control, radiation pyrometry, control/regulation system, etc., can solve the problem of consistent machine temperature and achieve the effect of eliminating the influence of part parameter errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

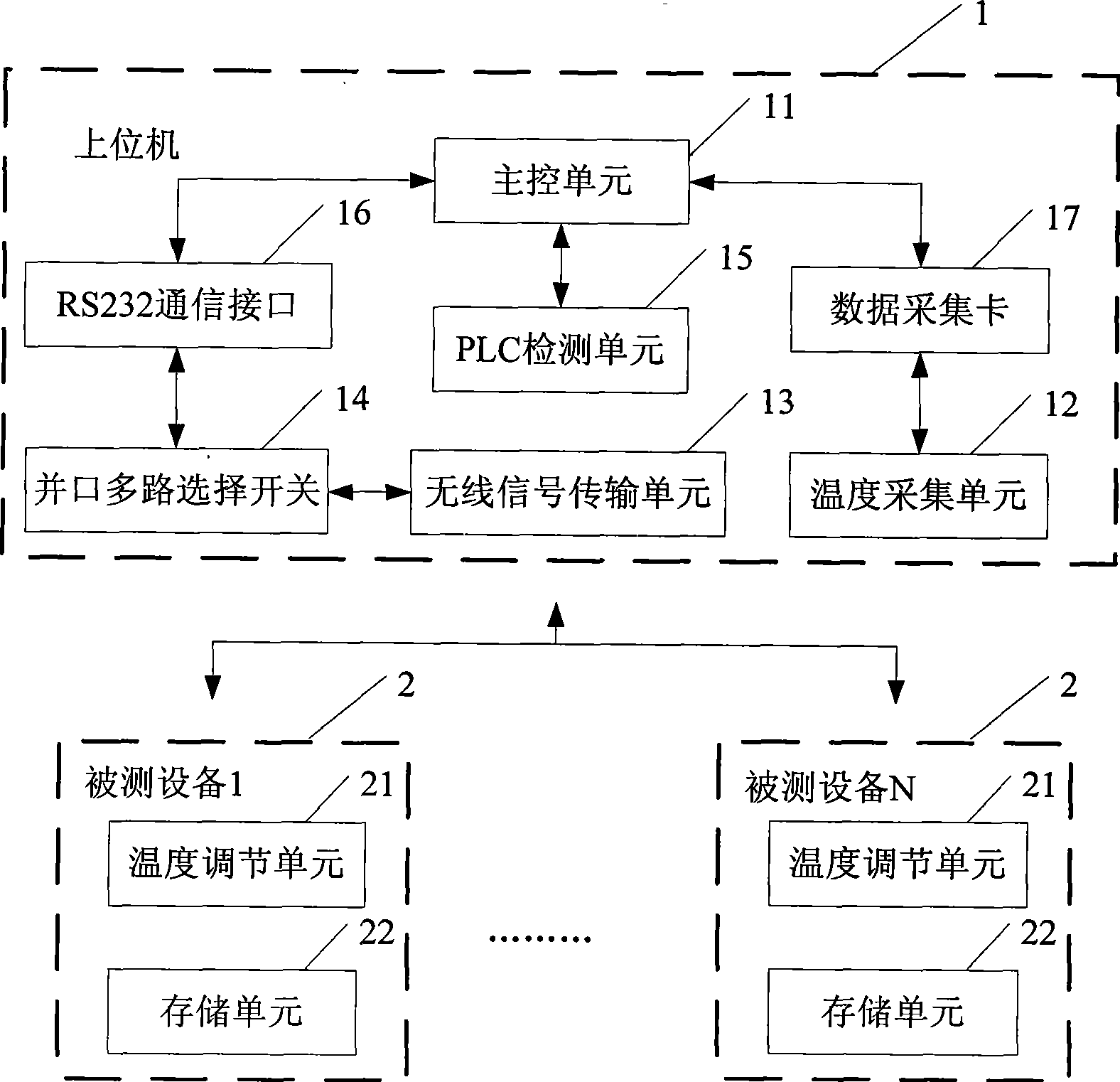

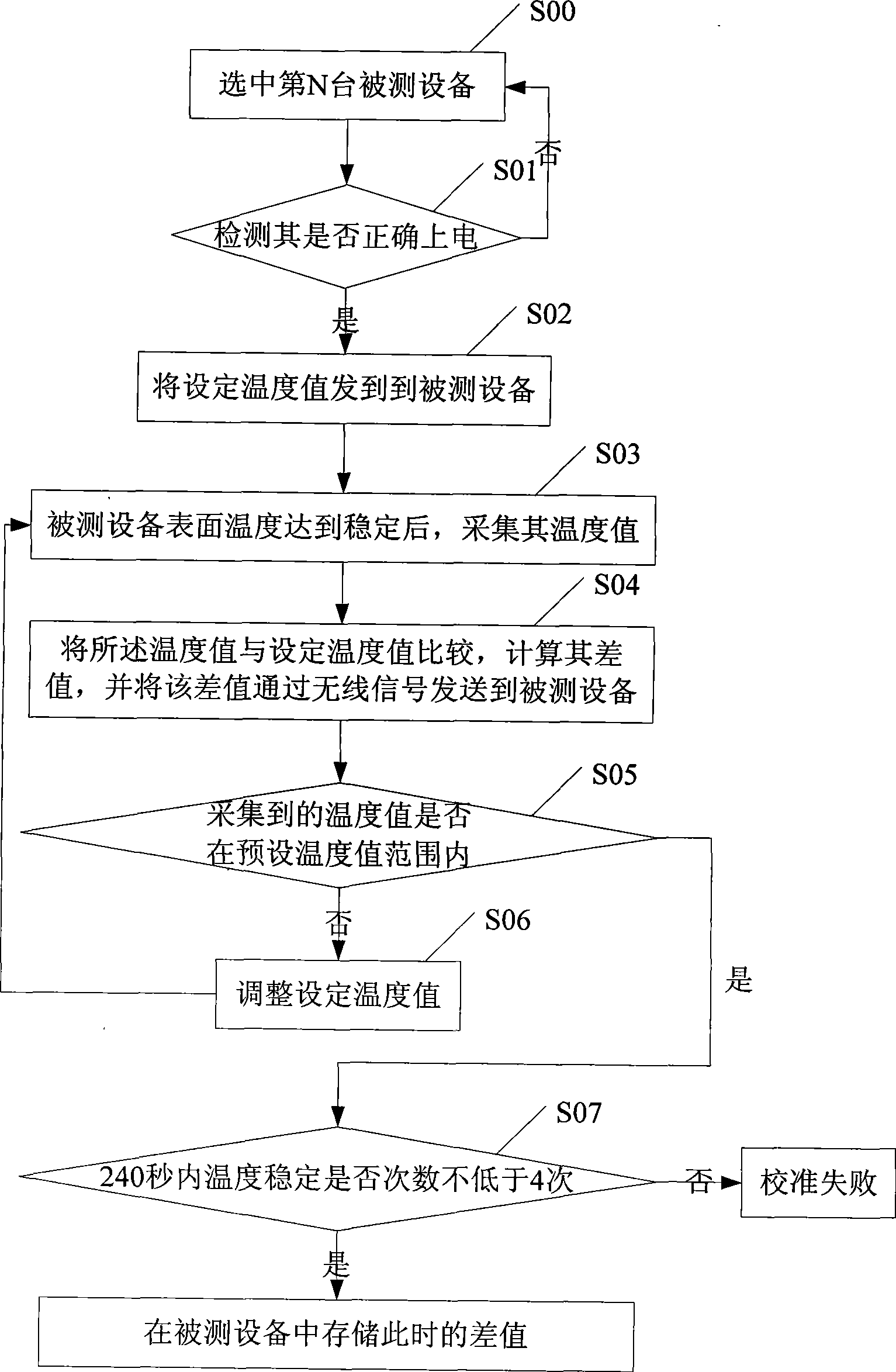

[0025] refer to figure 1 , this figure is a composition structure diagram of an embodiment of the temperature calibration system provided by the present invention; When, the host computer can be a host computer or a machine with a function similar to a host computer; the device under test is a hair straightener. Among them, the upper computer 1 is set with:

[0026] The main control unit 11 is used to send the set temperature value to the device under test, and calculate the difference between the actual temperature value of the surface of the device under test and the set temperature value, and send the difference to the device under test;

[0027] The temperature acquisition unit 12 is connected with the main control unit 11, and is used to collect the temperature value of the device under test after the surface temperature reaches a stable value, and transmit the temperature value to the main control unit 11. During specific implementation, it can pass Link to the main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com