Method for sealing sample room of mercury porosimeter

A technology of sample chamber and mercury porosimeter, which is applied to the sealing field of sample chamber of mercury porosimeter, can solve the problems of large difference in thickness, position and quality, sample cell rupture, affecting mercury quality, etc., and achieves improved accuracy and precision, extended Service life, reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

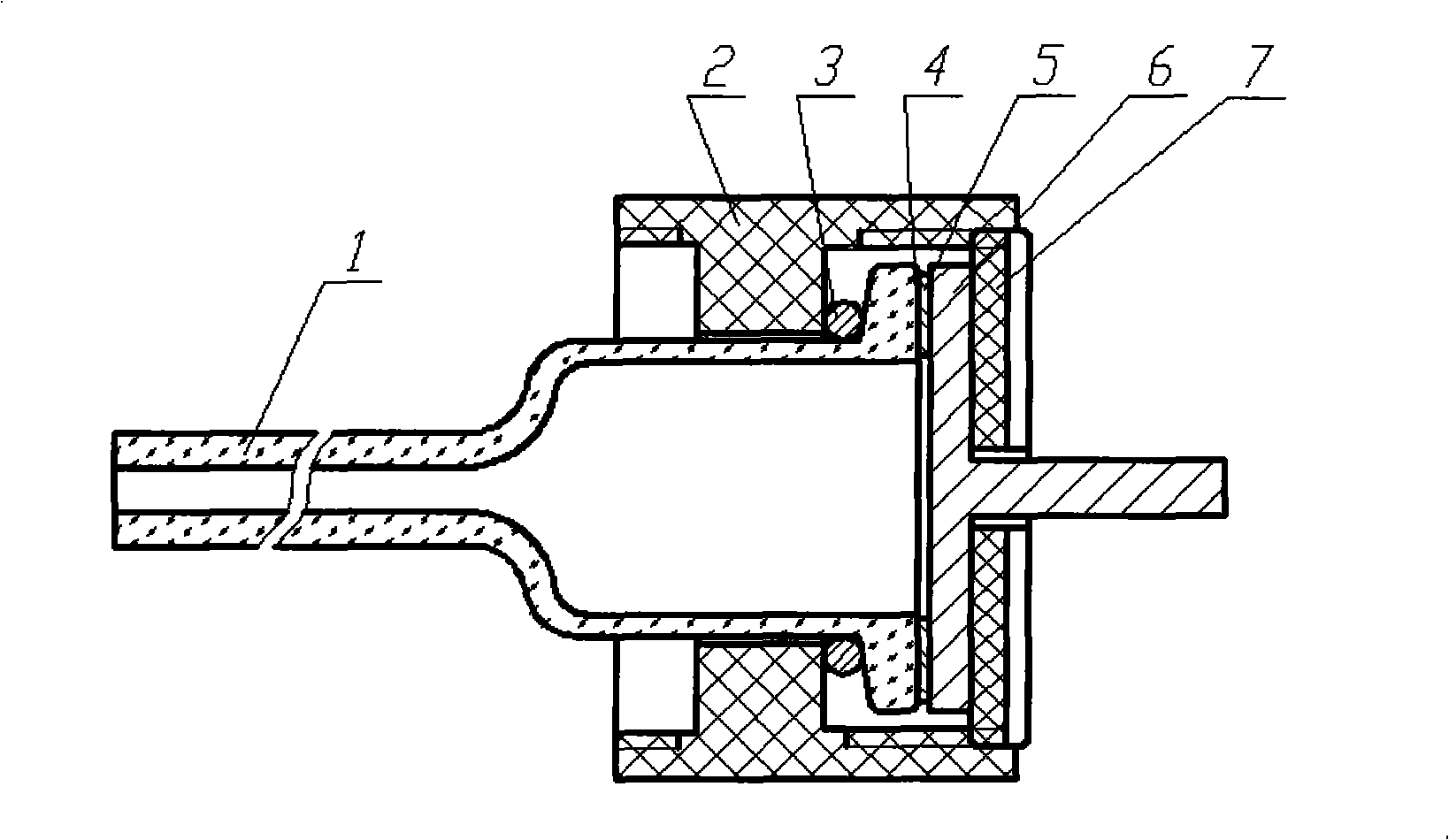

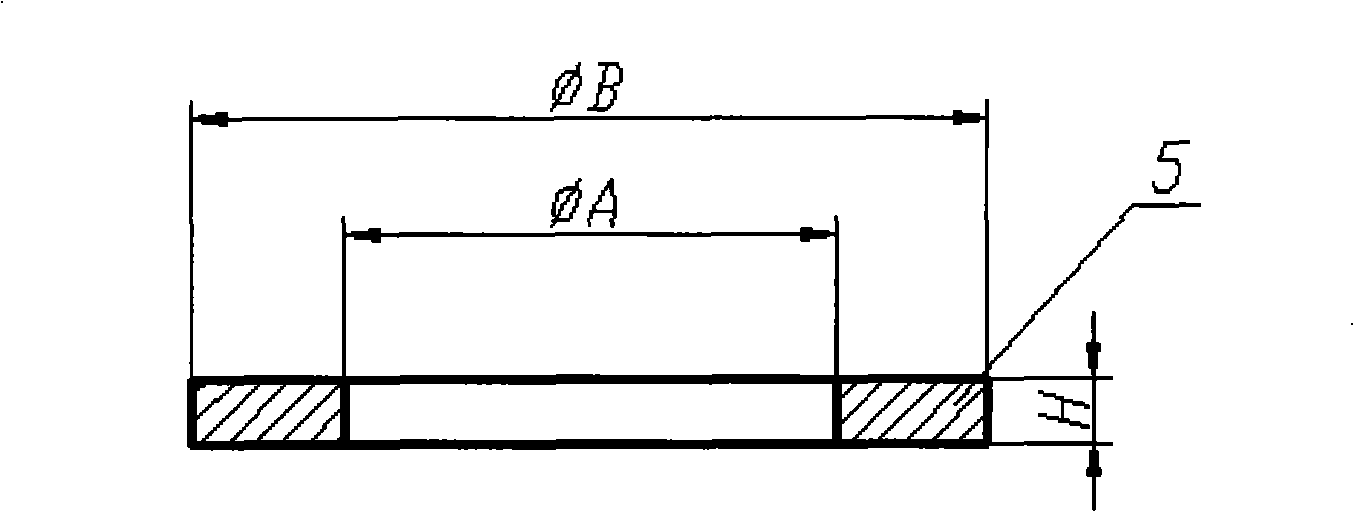

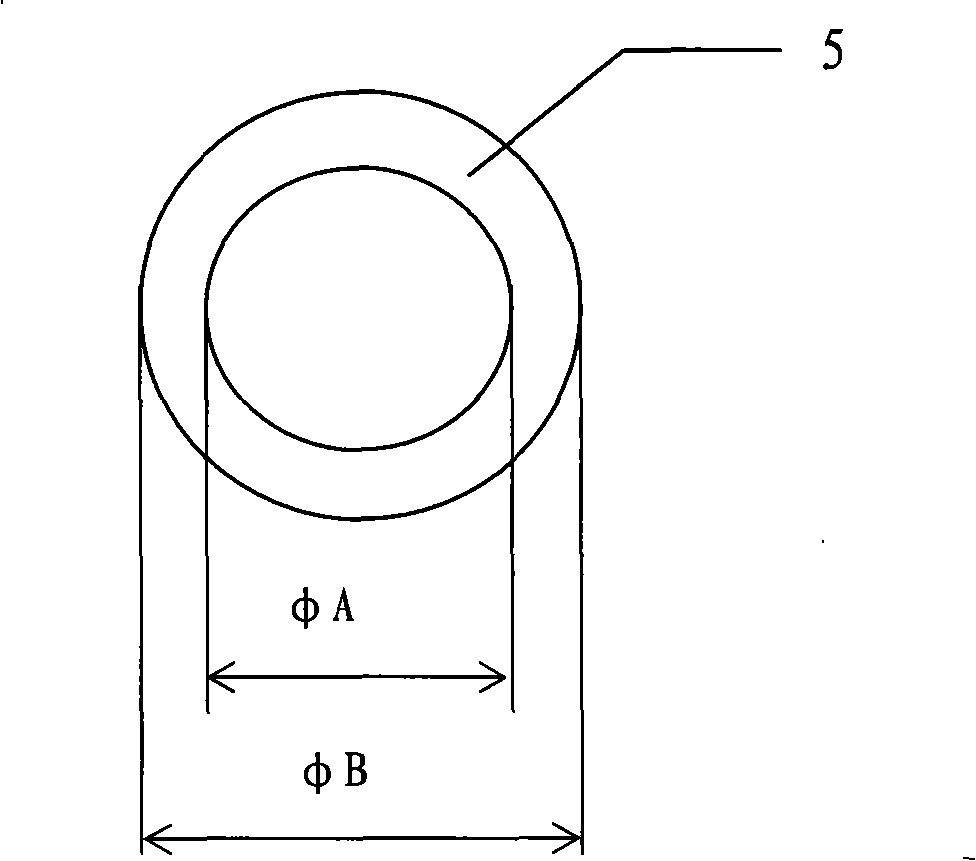

[0014] Embodiment 1: adopt the U.S. Quan-tachrome company mercury porosimeter, the composition of its sample chamber sees figure 1 , Corresponding to each label are: quartz glass sample cell 1, upper sample cell cover 2, O-ring 3, sample cell grinding port 4, gasket 5, stainless steel electrode contact assembly 6 and lower sample cell cover 7. figure 2 is a cross-sectional view of gasket 5, image 3 is a schematic plan view of the gasket 5, the inner diameter is A, the outer diameter is B, and the thickness is H. Among them, A and B are respectively consistent with the inner and outer diameters of the grinding port of the sample cell. A silicone rubber gasket 5 with a thickness H of 0.5 mm is placed between the ground port 4 of the sample cell and the stainless steel electrode contact assembly 6 to seal the sample chamber. For porous SiO with a pore diameter of 7.3±0.5nm 2 The standard sample was tested, and the vacuum time of the low-pressure mercury injection with a vacu...

Embodiment 2

[0015] Example 2: The test method is the same as in Example 1. A nylon gasket with a thickness of 0.1 mm is used for sealing. The time for vacuuming under low pressure is 13 minutes. The pore diameter obtained by the test is 7.48 nm.

Embodiment 3

[0016] Example 3: The test method is as in Example 1, a rubber gasket with a thickness of 1.0 mm is used for sealing, the time of vacuuming under low pressure is 10 minutes, and the pore diameter obtained by the test is 7.38 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com