An automobile drive disc assembly

A driving disc and assembly technology, which is applied in transmission devices, fluid transmission devices, rigid shaft couplings, etc., can solve problems such as high precision requirements for parts matching, adverse effects of crankshaft design, special parts and mold costs, etc. Achieve the effects of reducing processing procedures, improving collection accuracy and reliability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

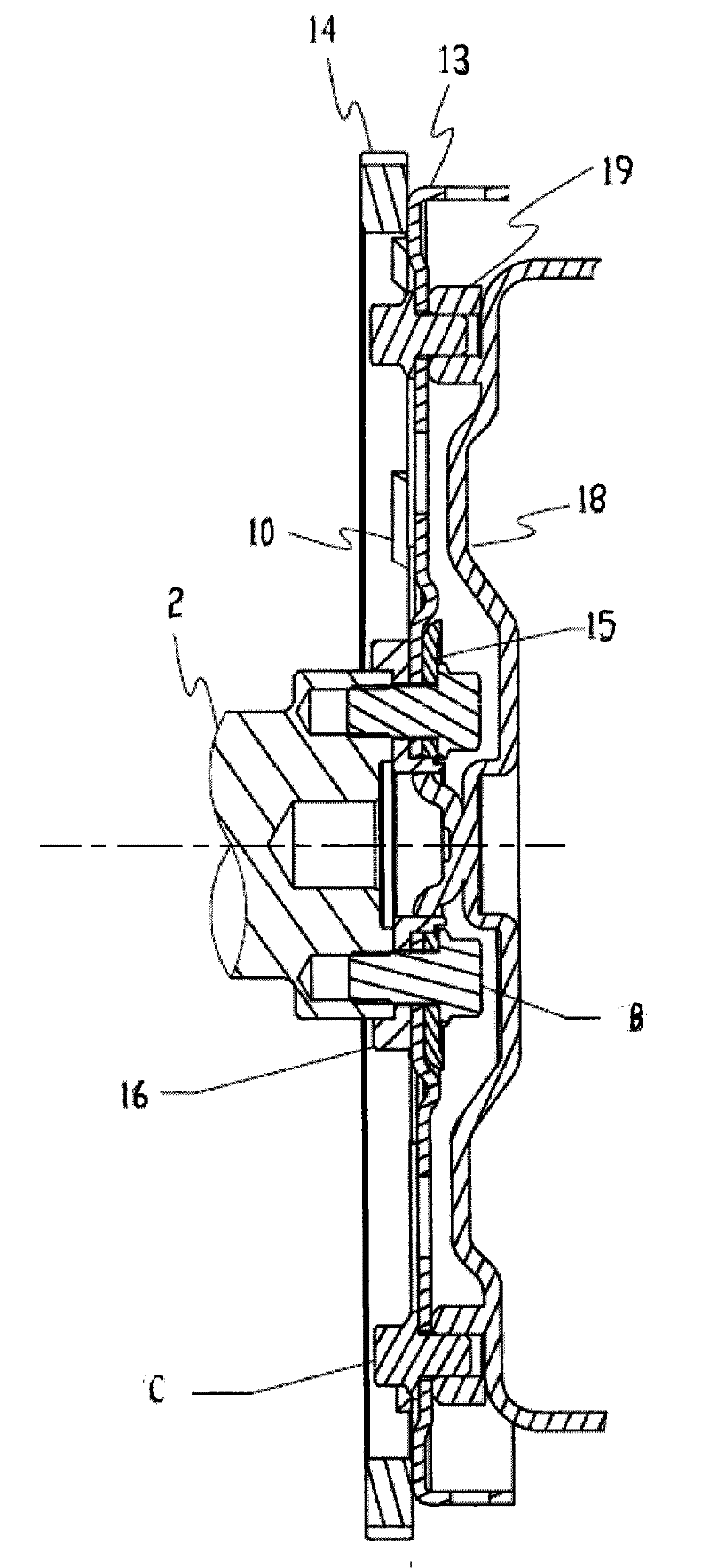

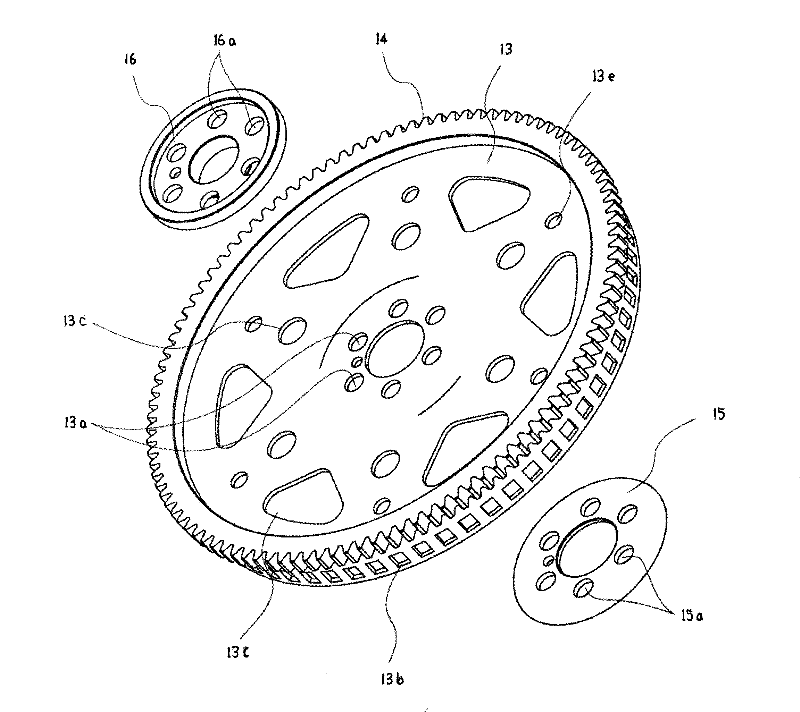

[0012] The driving disc assembly is used to connect the automatic transmission and the engine, transmit torque, and provide the position signal of the crankshaft.

[0013] Such as figure 2 As shown, the driving disc assembly includes a driving disc body 13, a starting ring gear 14 and a signal tooth 13b. The driving disc body 13 is disc-shaped and has a central hole. The signal teeth 13b are directly stamped on the outer peripheral wall of the drive disc body, and the number is 60 teeth, which are evenly distributed on the circumference of the disc body and are perpendicular to the main disc body at 90 degrees. To determine crankshaft phasing, 2 teeth are culled consecutively at a specific angle. The signal tooth 13b must be processed according to the specification requirements of the sensor for the signal tooth, so as to ensure the continuity and validity of the signal. The runout of the outer circumference of the signal tooth 13b must meet the clearance tolerance require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com