Heavy-duty universal coupling device used for coupling drilling tool and drilling rod

A universal connection and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve problems affecting construction safety and progress, and damage to weak links related to rigid connections, so as to improve the stress situation and solve the problem of rigidity Connection problem, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

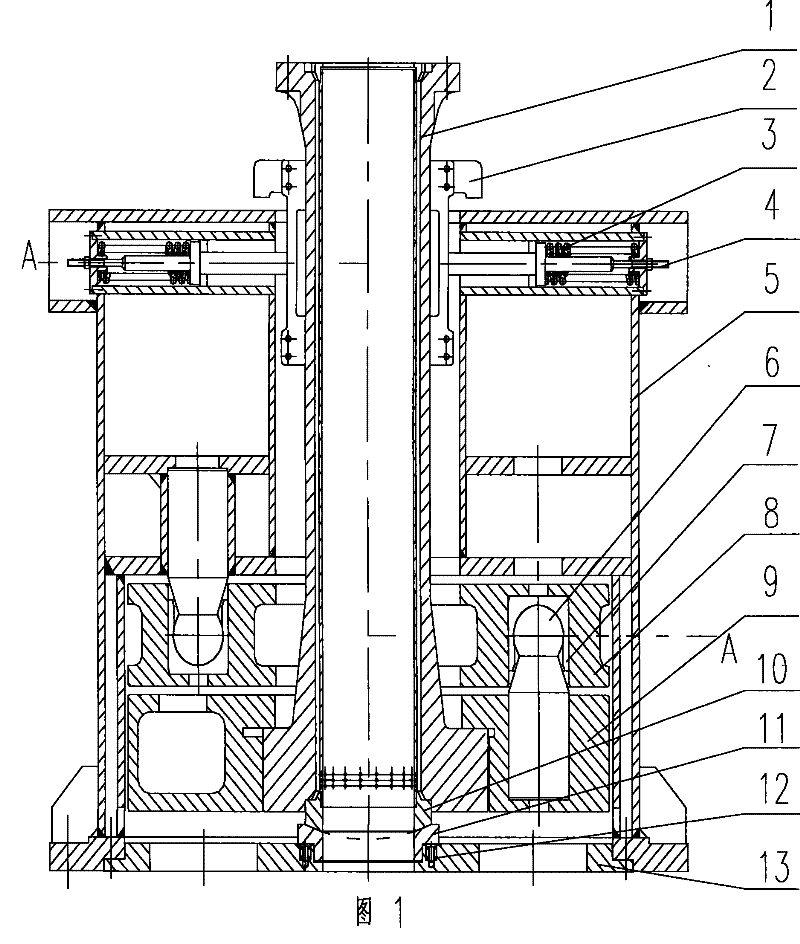

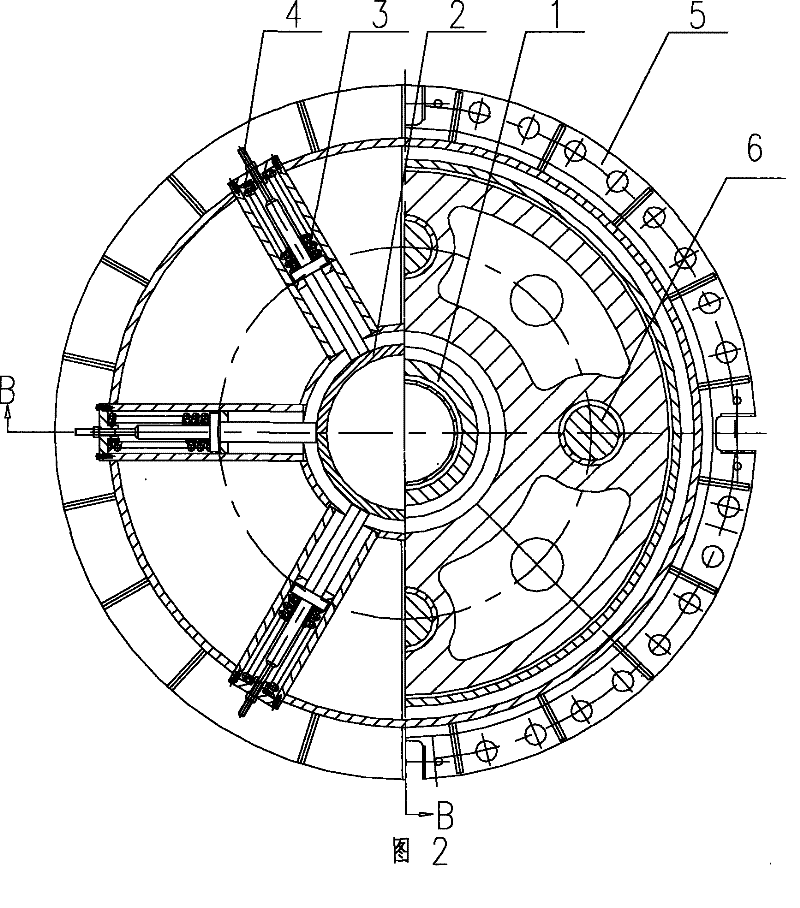

[0015] Such as figure 1 , 2 Shown: the present invention is used for the heavy-duty universal connection device that connects drilling tool and drill pipe and is mainly made up of central pipe 1, intermediate sleeve 2, spring 3, small shaft 4, housing 5, ball end cylindrical pin 6, resistant The grinding sleeve 7, the upper transition plate 8, the lower transition plate 9, the lower spherical surface 10, the upper spherical surface 11, the butterfly spring 12, and the support plate 13 are composed of the central tube 1 installed in the middle of the labyrinth shell 5, and the upper end of the central tube 1 Install the middle sleeve 2, distribute six small shafts 4 evenly along the circumference of the middle sleeve 2, each small shaft 4 is installed in the special round tube of the housing 5, and install a spring 3 at the tail of the small shaft 4; the central tube The lower end of 1 is press-fitted with a lower spherical surface 10, and correspondingly provided with an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com