Special A type rack type air spring rear suspension for large-scale bus

An air spring and rear suspension technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problem of the lack of independent development of bus air suspension, the inability to adapt to the production process of full-load bus, and the dynamic capacity of multi-axle axles. Large and other problems, to achieve the effect of light weight, simple structure, reduction of vertical pitch and lateral swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

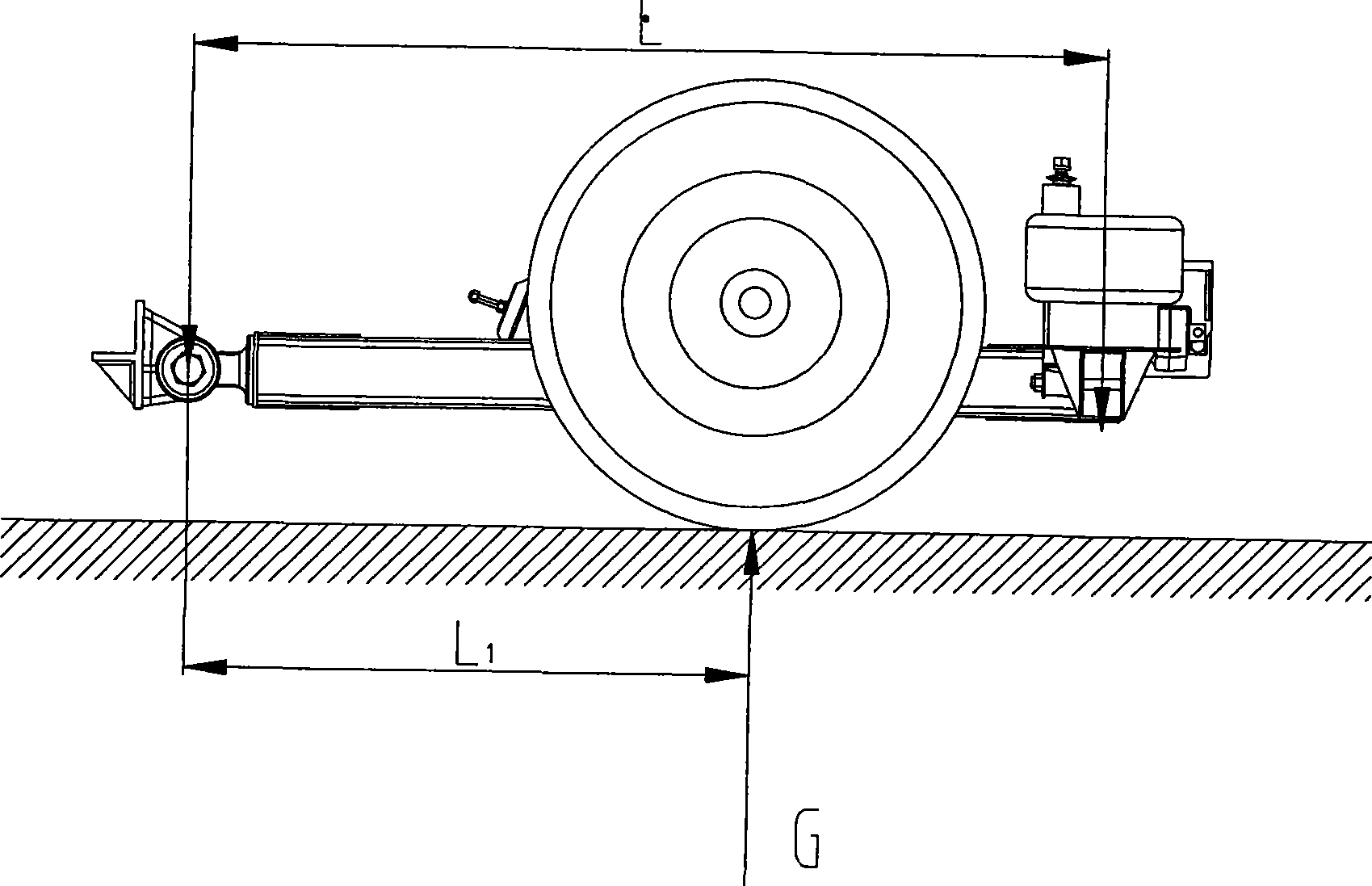

[0041] Below in conjunction with accompanying drawing, the present invention will be described in further detail with 12 meters of two-step bus prototype examples.

[0042] Such as figure 1 As shown, the A-frame 1 is connected with the driving rear axle 13 through the axle fastener 3, the front end of the A-frame 1 is connected with the coupling assembly 2, and the rear end of the A-frame 1 is provided with an air spring airbag assembly 4 in turn. And the shock absorber 5, the A-frame 1 is provided with a flexible connection end support of the height control valve, and the rear end of the A-frame 1 is connected with a horizontal stabilizer bar 6.

[0043] Such as figure 2 , Figure 5 As shown, the A-frame 1 includes an A-frame body 7, the front end of the A-frame body 7 is provided with a front connecting plate 23, the rear end is connected with a rear beam 24, and the front end and the rear end of the A-frame body 7 are connected with the rear beam 24 The upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com