Technique for processing poly-angle part blade supporting seat

A processing technology and support seat technology, which is applied to the processing technology field of the multi-angle part blade support seat, can solve the problems of complex processing technology, low processing quality and low processing efficiency, and achieve simple tooling structure, good usability and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

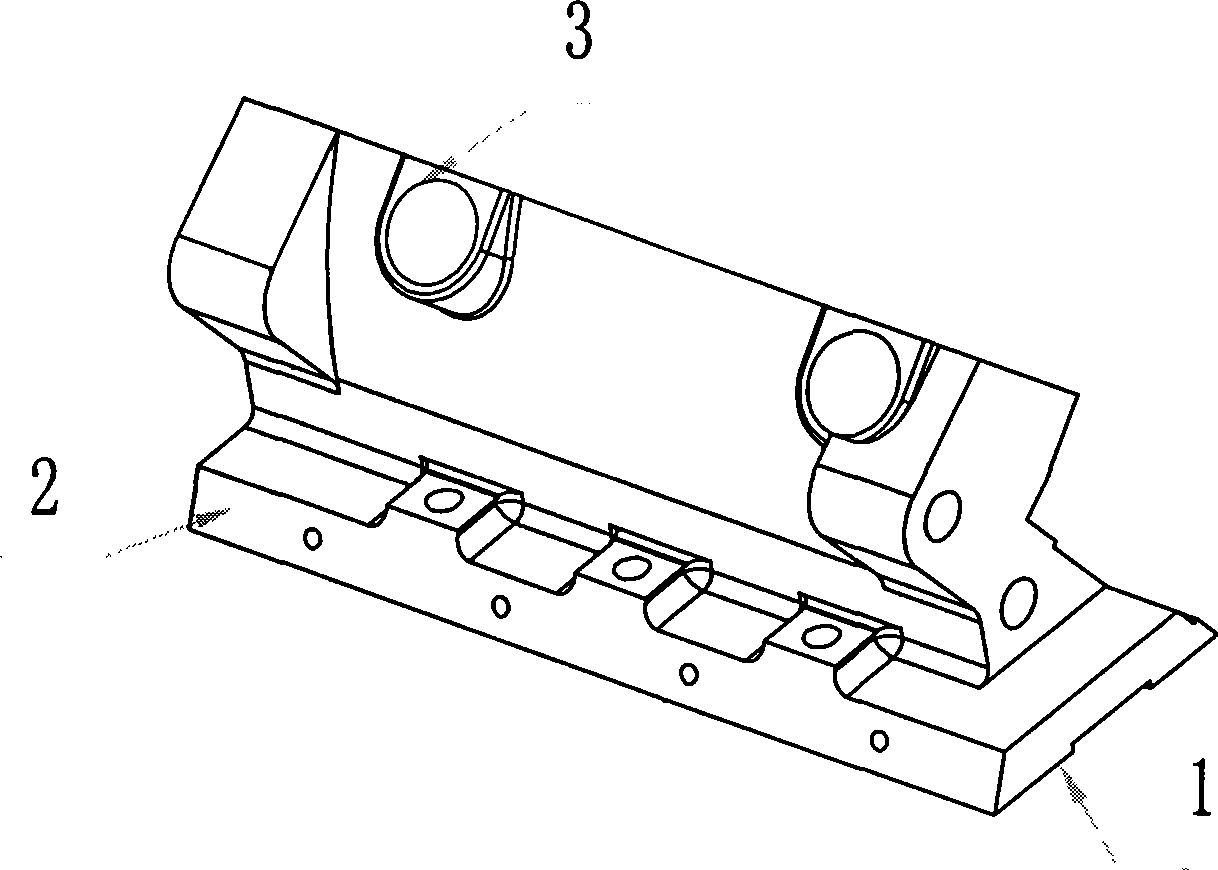

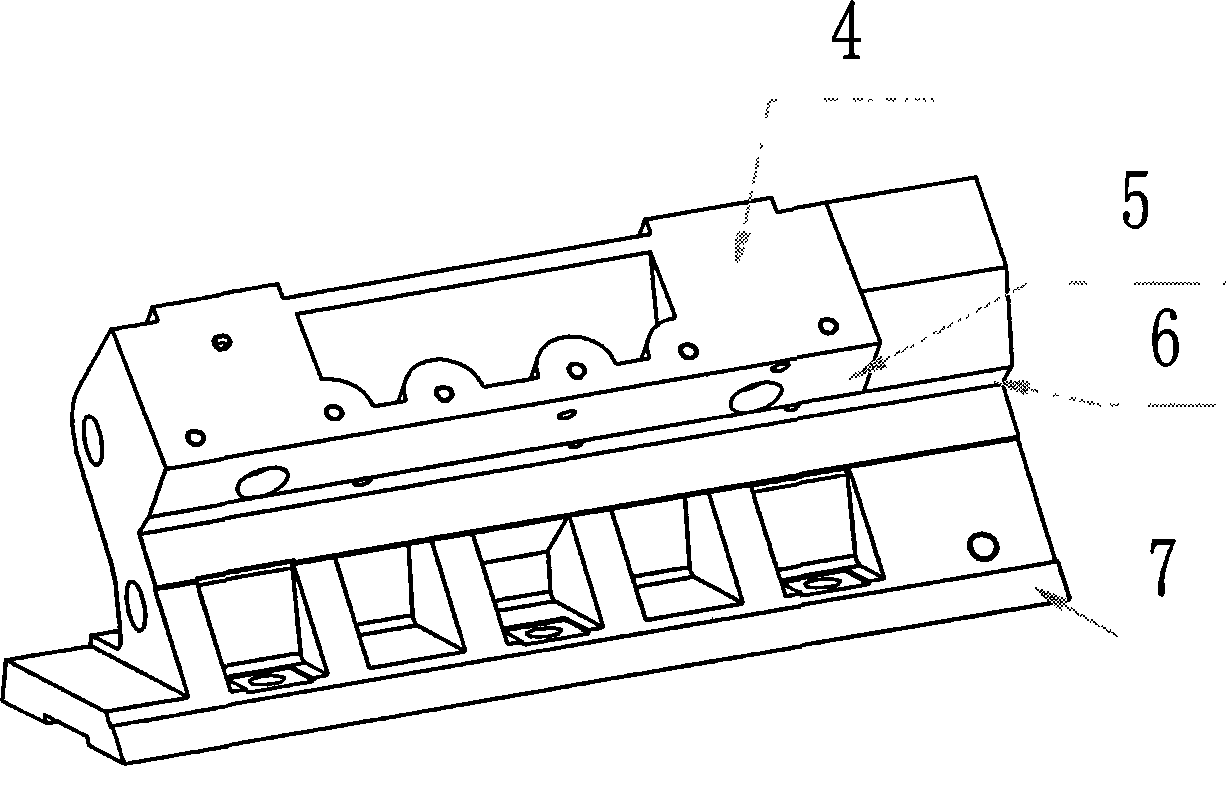

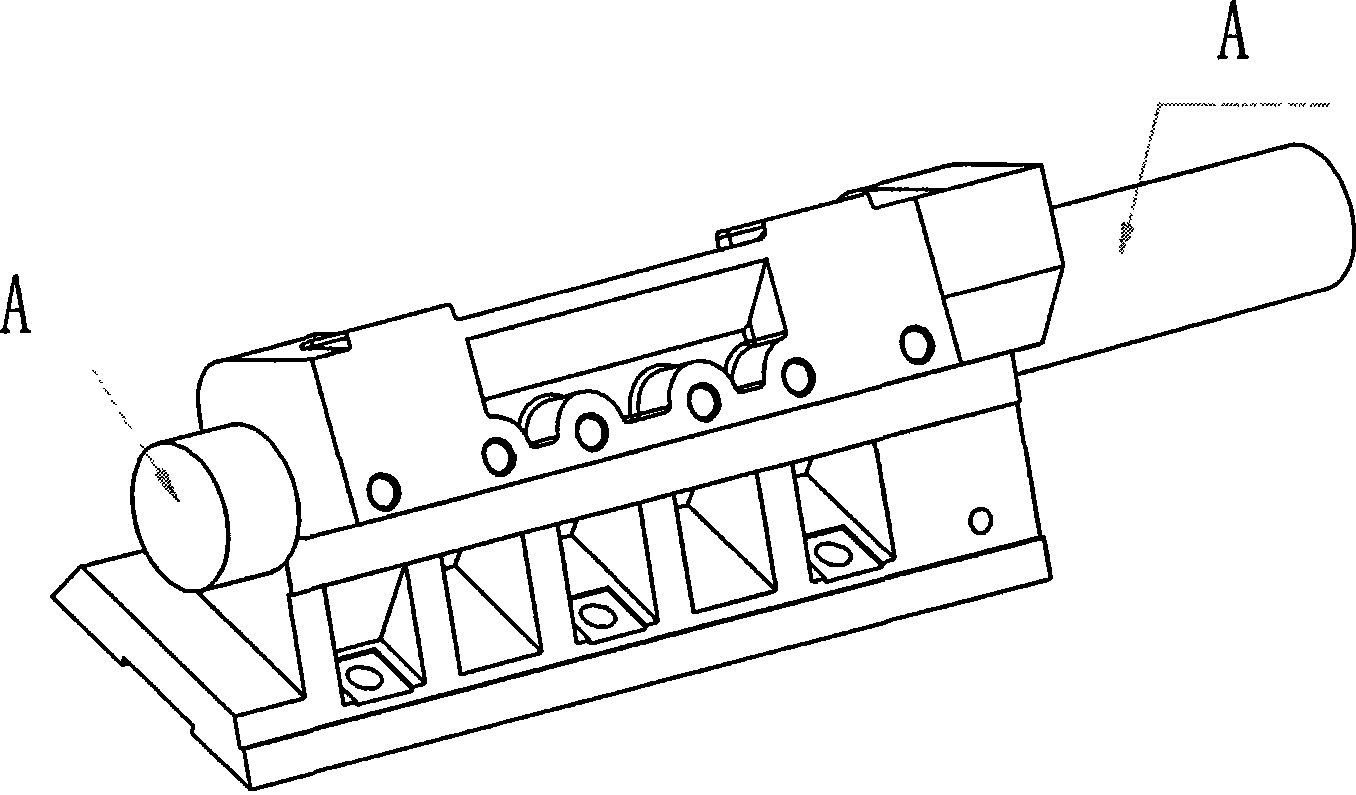

[0019] Such as Figure 1~3 , The blade support seat of multi-angle parts is processed on a four-axis linkage horizontal machining center. First, determine that the equipment required for processing is a four-axis linkage machining center. According to the equipment used for processing, design the positioning fixture and the tools used. A circular hole is milled on both ends of the blade support seat, and a coaxial process support A is welded at the position of the circular hole, so that the two process supports A reach the required size. Take the process support A as the rotary axis and install it on the positioning fixture, take the 40mm wide groove of the blade support seat and the large surface 1 of the 6-φ12 hole as the 0° surface for processing, and use the 3D software to obtain other surfaces 2, 3, and 3. 4. The angles between the vertical lines passing through the center of revolution of face 5, face 6 and face 7 and the perpendicular line of face 1 are α1, a2, α3, α4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com