Device for producing a three-dimensional object in layers

A technology of three-dimensional objects and objects, applied in the direction of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as the inability to optimize working conditions, and achieve the effect of improving surface characteristics and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

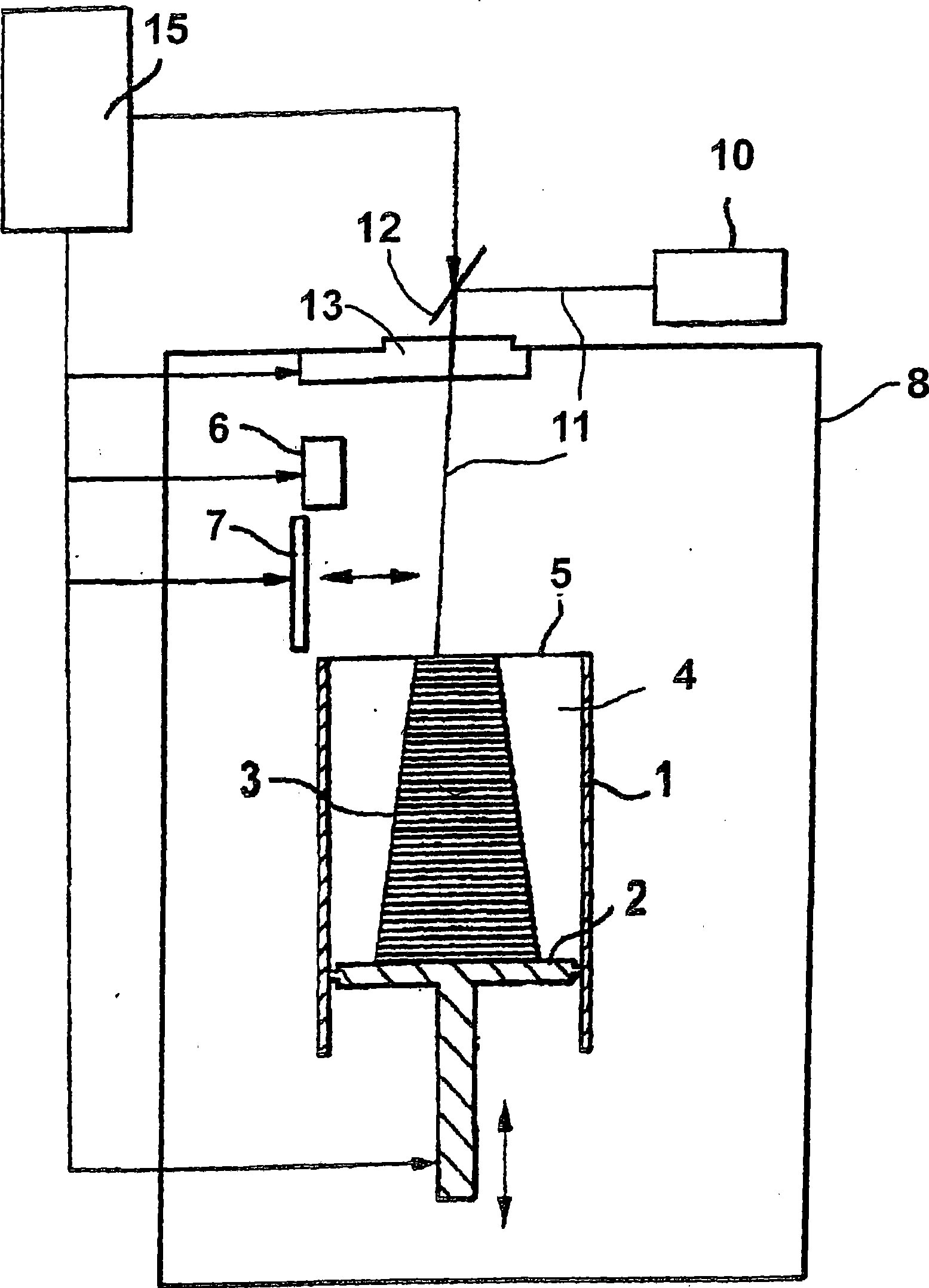

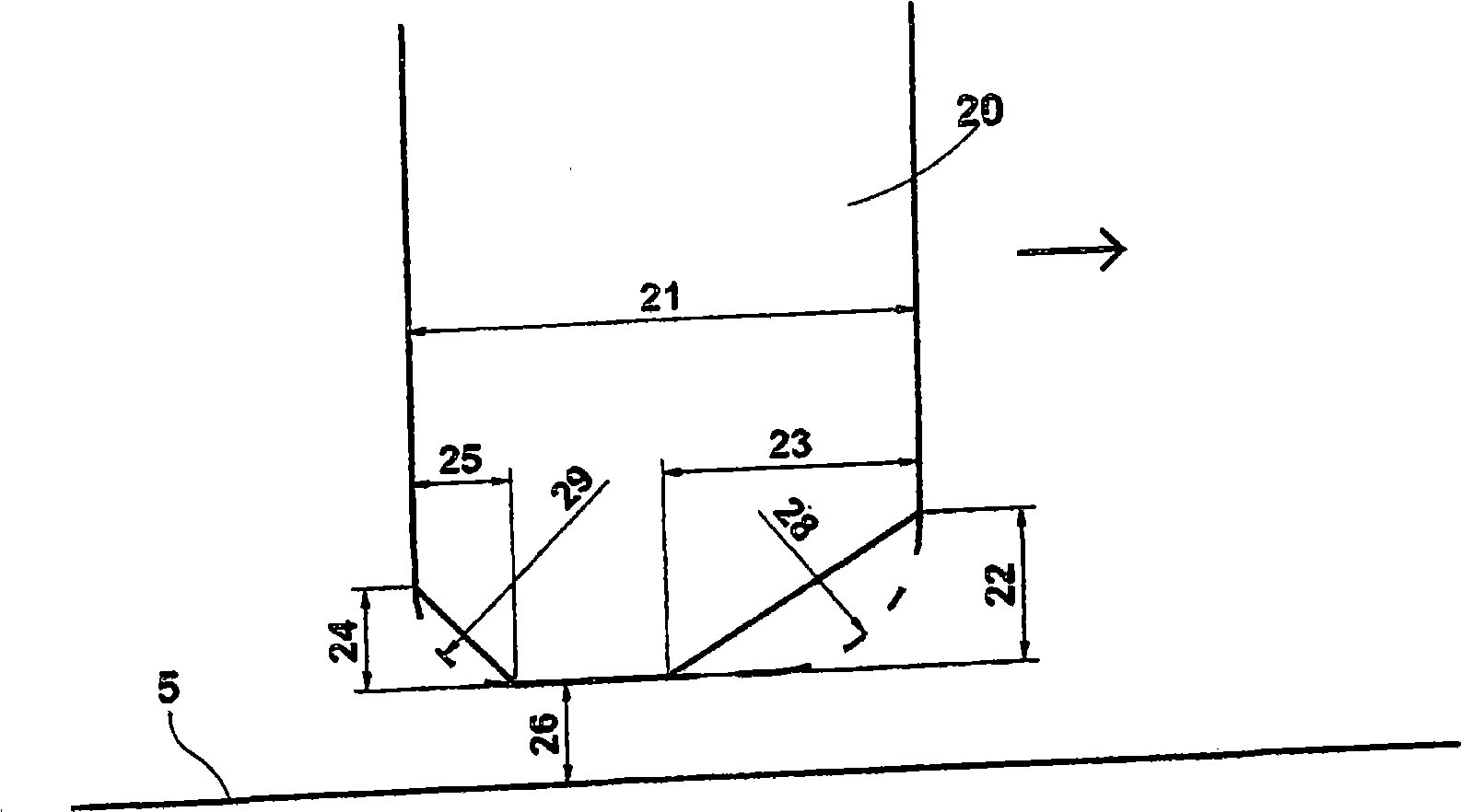

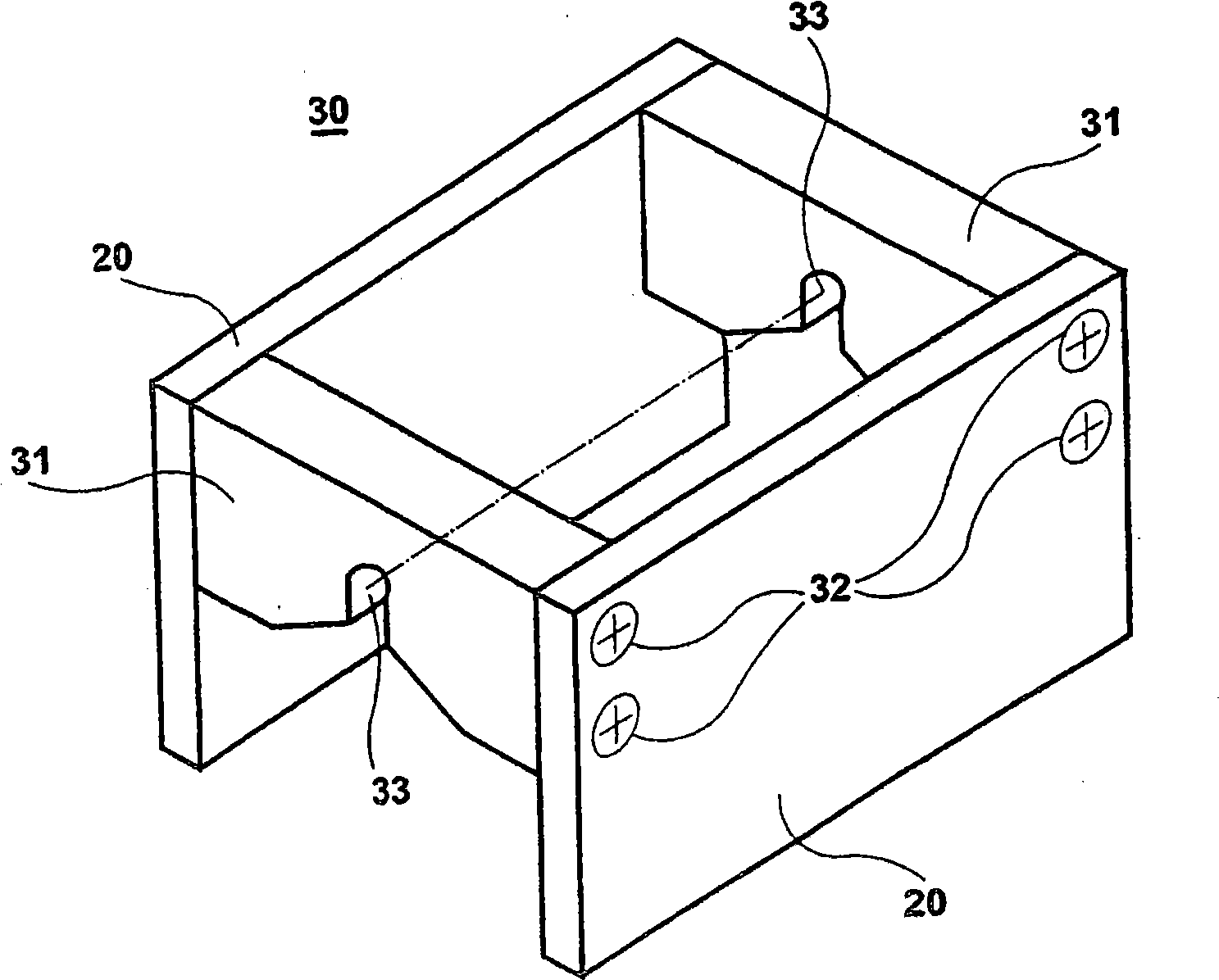

[0015] The following will refer to Figure 1 to Figure 4 An exemplary apparatus for layer-by-layer manufacturing of three-dimensional objects according to the present invention is described.

[0016] As an example of an exchangeable coating module used in coating, a doctor blade module is given here.

[0017] Such as figure 1 As shown, the device for the layered manufacture of objects has an upwardly open structural container 1 . Arranged in the container 1 is a carrier 2 with a substantially planar upper side oriented substantially parallel to the upper edge of the structural container. The support 2 is designed to support the object 3 to be formed. exist figure 1 The object 3 to be formed is shown in an intermediate state in which a plurality of layers of powdered constituent material have been selectively cured and surrounded by uncured constituent material 4 . Such as figure 1 As indicated by the vertical double arrow, the stand 2 can be moved in the vertical directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com