Intelligent monitoring system for boiler and heat exchange station

An intelligent monitoring system and heat exchange station technology, applied in heating systems, household heating, household heating and other directions, can solve the problems of energy waste, difficult heat demand changes in boilers and heat exchange stations, large equipment loss, etc. Improve operational reliability and safety, ensure reliability and safety, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Boiler and heating network intelligent monitoring system and method thereof proposed by the present invention are described as follows in conjunction with accompanying drawings and embodiments:

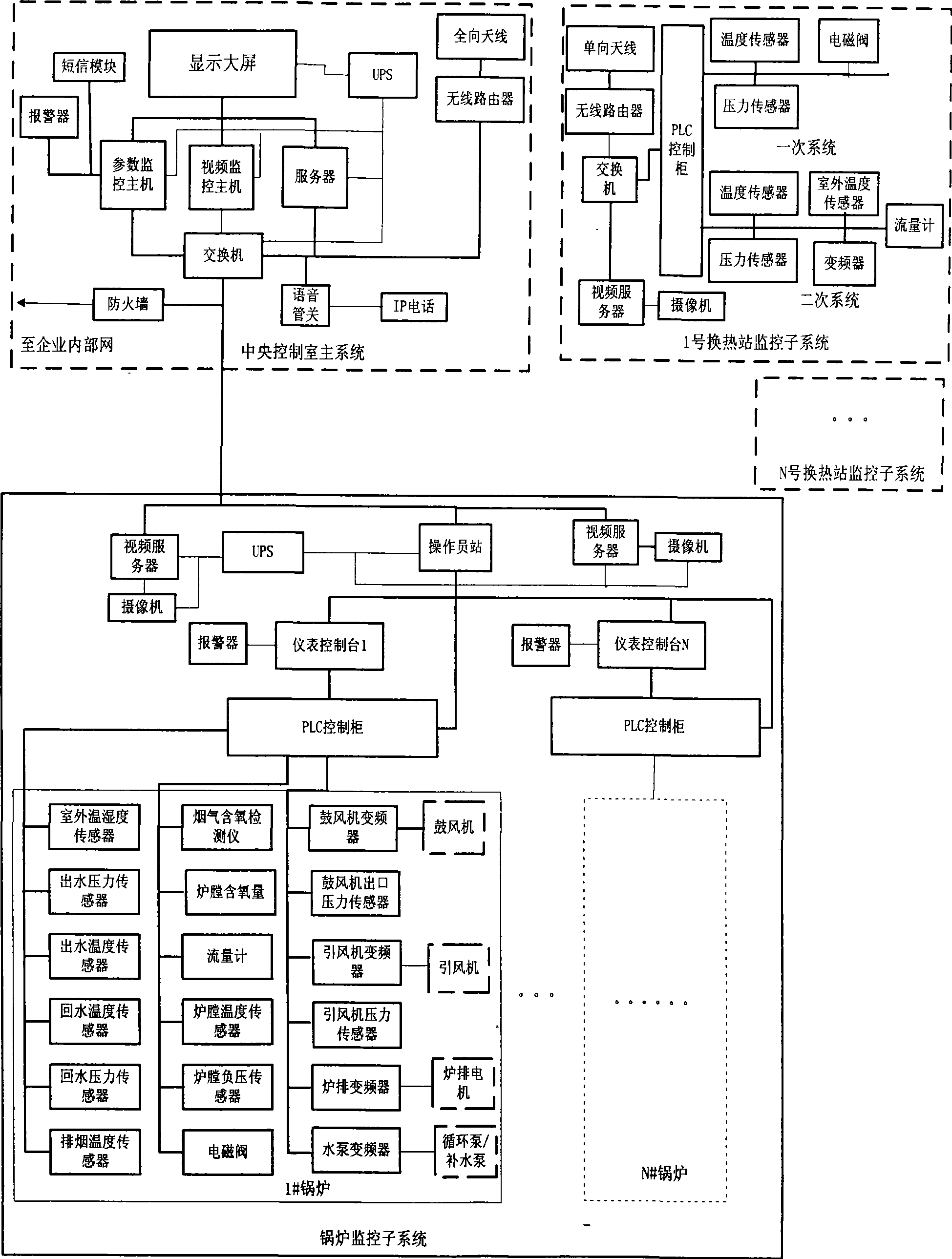

[0021] The overall structure of the boiler and heating network intelligent monitoring system of the present invention is as follows: figure 1 As shown, the system consists of the main system of the central control room, the boiler monitoring subsystem connected to the main system of the central control room and multiple heat exchange station subsystems (each heat exchange station is provided with a heat exchange station subsystem);

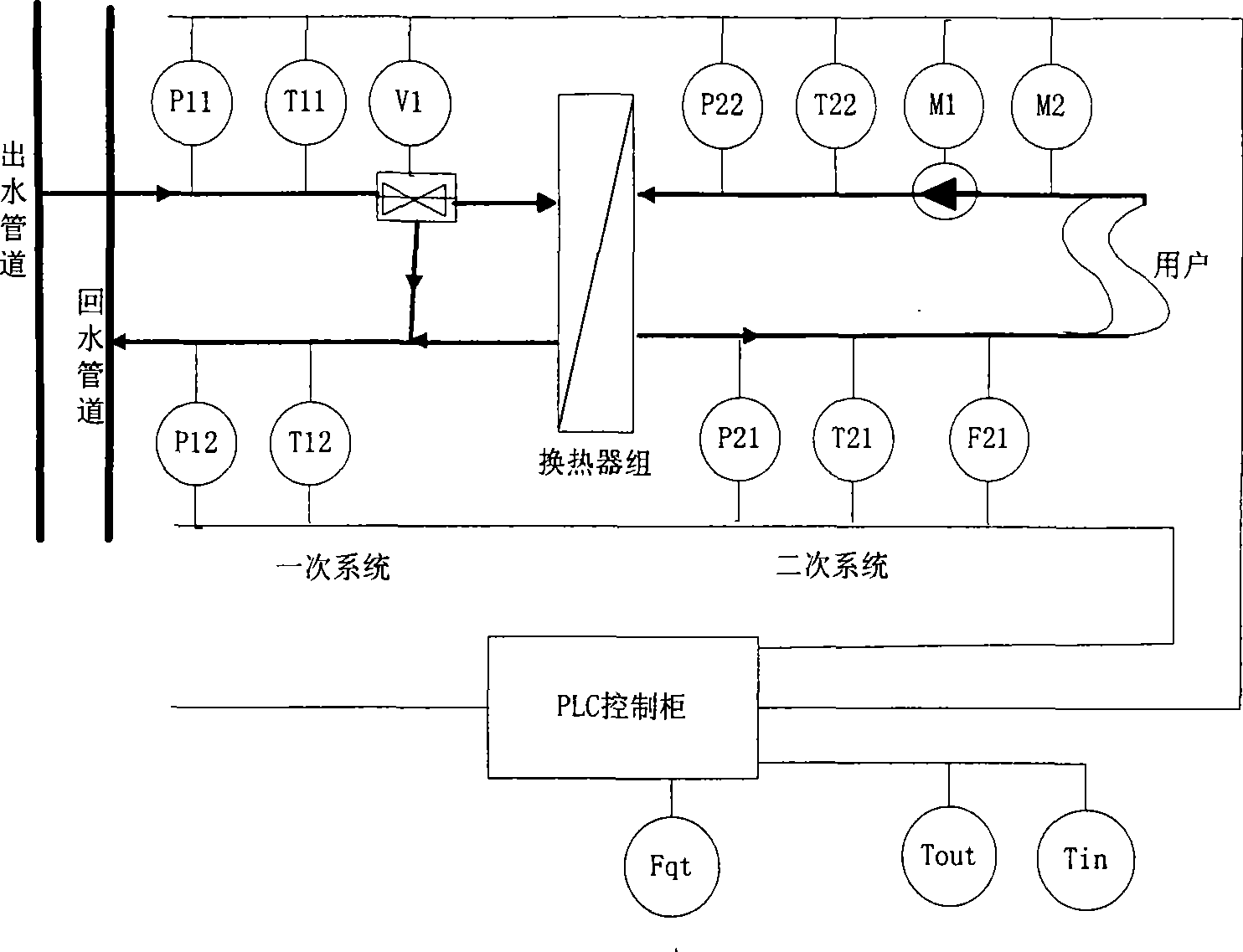

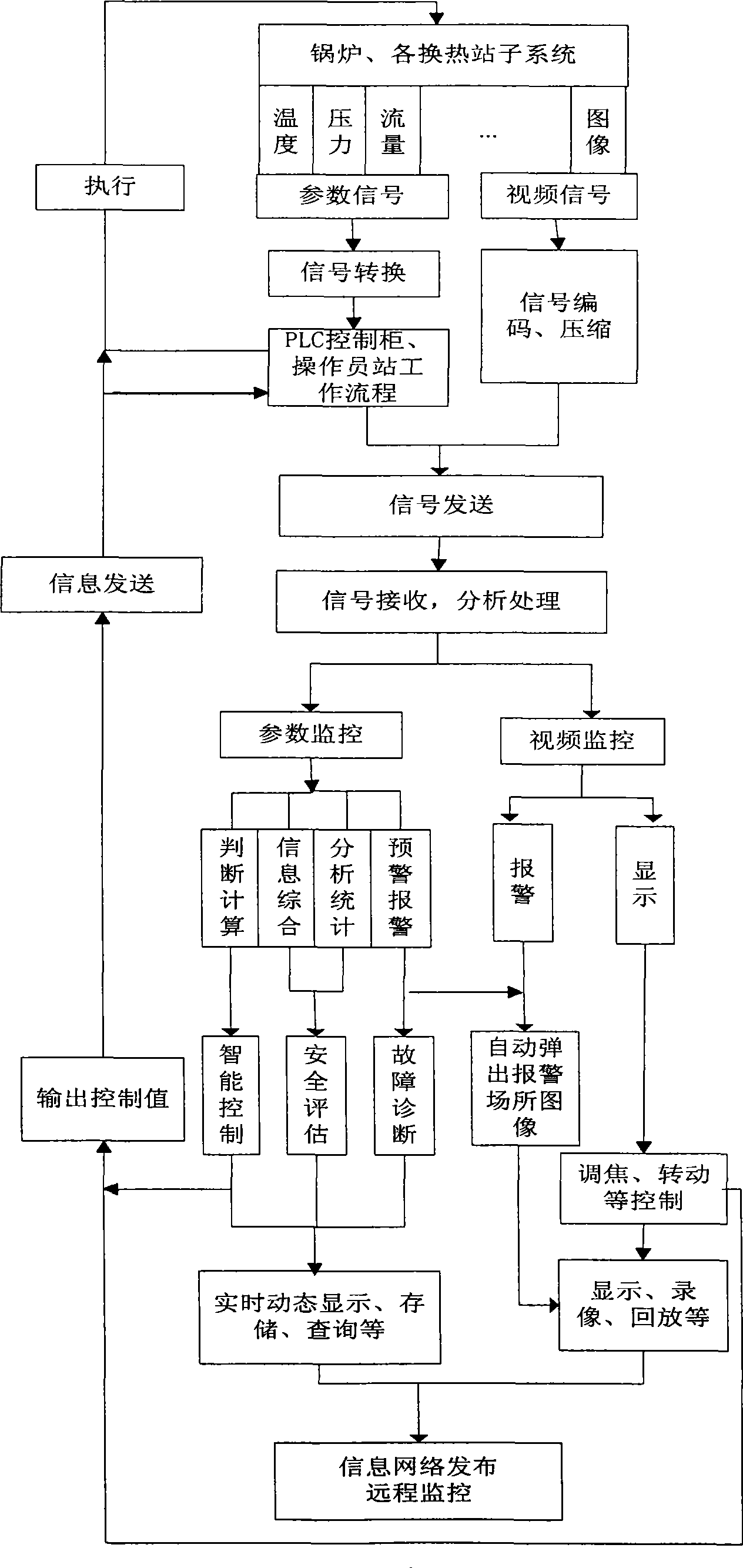

[0022] The main system of the central control room is used to process and analyze various data received from the boiler monitoring subsystem and the monitoring subsystem of each heat exchange station, and calculate the water circulation time period of the monitored primary system and secondary system , Atmospheric temperature, user type, heat load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com