Garbage pyrolysis furnace

A pyrolysis furnace and waste technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems that the treatment process cannot meet expectations, the design has not been given sufficient attention, and can meet the stability requirements and design. Simple and effective sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

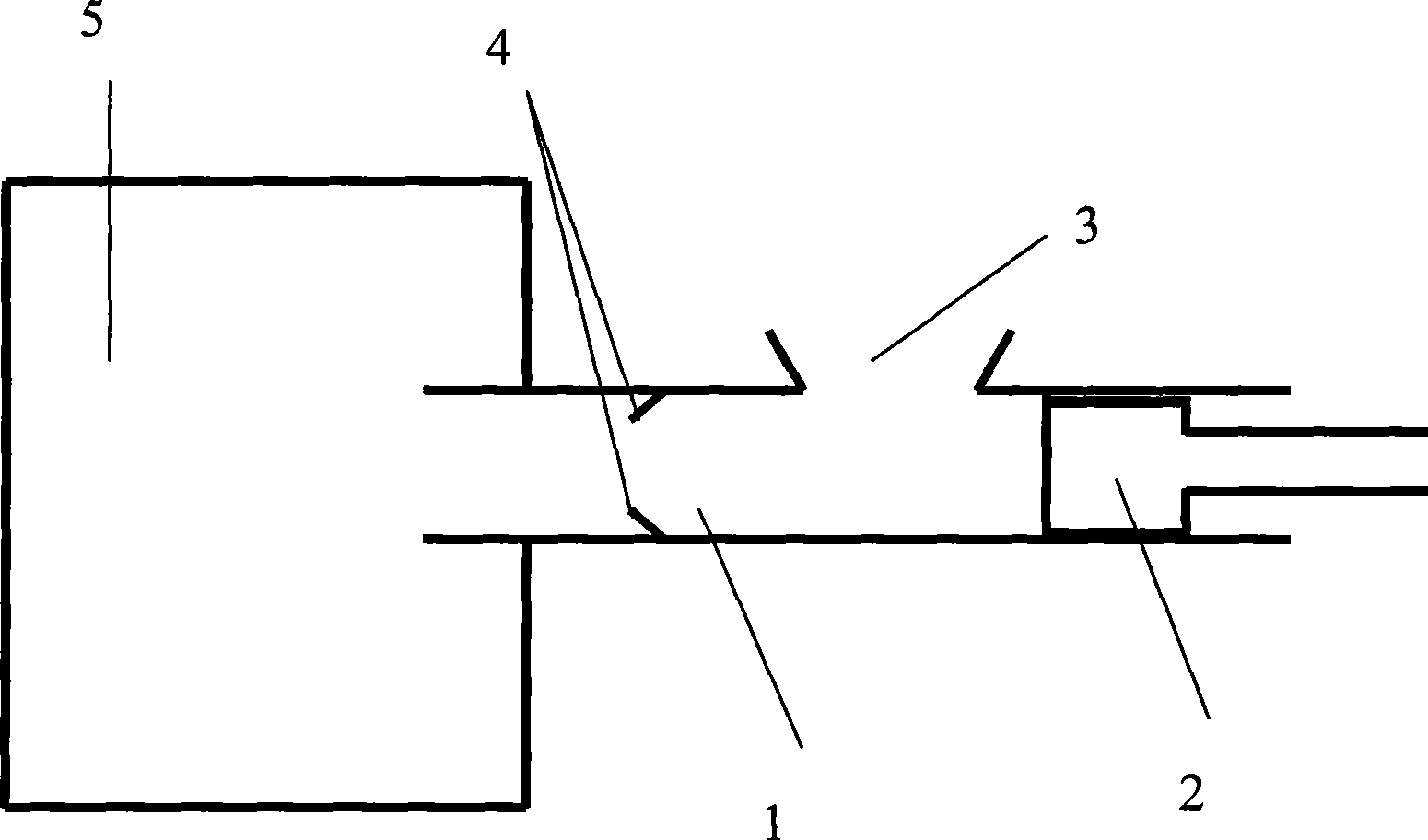

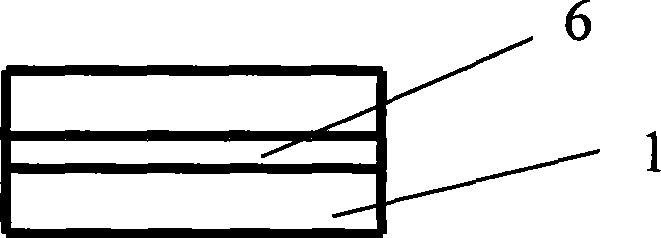

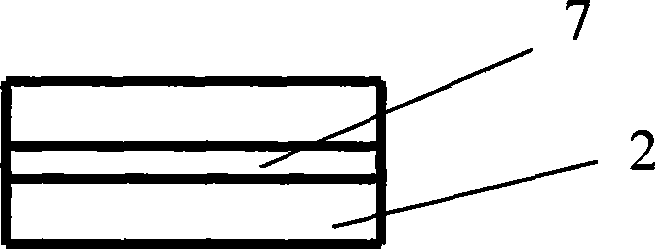

[0019] This feed device is made up of feed pipe 1 and piston 2. The upper end of the feed pipe 1 has a feed inlet 3, and the diameter of the opening in the furnace becomes larger or unchanged, and the feed pipe is located between the outer end of the furnace wall and the feed inlet 3, and an inwardly shrinking shrink ring 4 is provided. The garbage is poured into the feeding pipe 1 from the feeding port 3, and the piston 2 pushes the garbage into the pyrolysis furnace 5 under the action of an external force. Meet the requirements of insulating gas. A small groove 7 is processed on the bottom surface of the piston 2. During the feeding process, the moisture and air contained in the garbage can be discharged from the groove 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com