Biocompatibility pre-gelatinized modified starch and preparation thereof

A technology of biocompatibility and modified starch, applied in application, medical science, absorbent pads, etc., can solve the problems of poor water absorption, difficult to achieve hemostasis, small starch, etc., achieve non-toxic side effects, avoid residues, and be safe to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

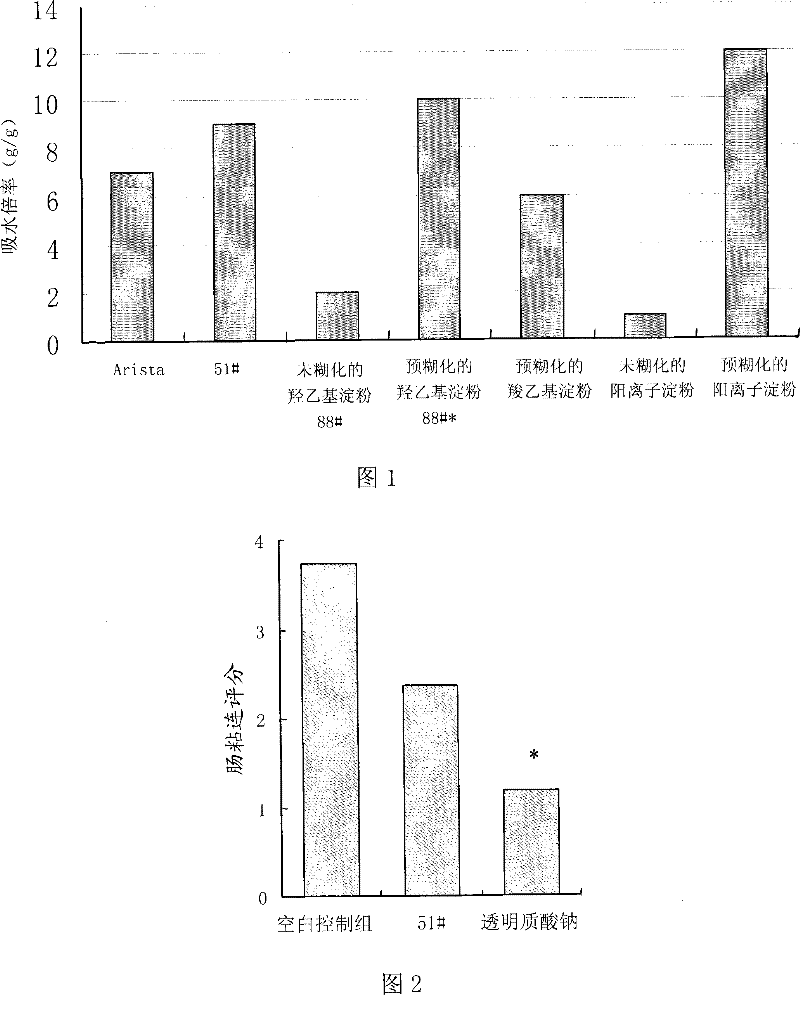

[0096] A biocompatible pregelatinized modified starch is pregelatinized hydroxypropyl distarch phosphate, and the original starch (tapioca starch) is etherified, crosslinked, and esterified with chemical reagents such as propylene oxide and phosphoric acid. After multiple times of denaturation, it is made into hydroxypropyl distarch phosphate, and then pregelatinized and denatured by spray drying method to make pregelatinized hydroxypropyl distarch phosphate. Then put the pre-gelatinized hydroxypropyl distarch phosphate raw material in the boiling machine at 40-50°C, add distilled water, undergo coagulation, pelletizing, and sieve to make modified starch 51# (manufacturer Starch Medical Inc. batch number 071025), the molecular weight is 10,000-2,000,000 Daltons, the particle size is 10-1000 μm, and the starch granules with a particle size of 30-500 μm account for not less than 95% of the total starch granules, and the particle size is preferably 50-500 μm.

[0097] The viscosi...

Embodiment 2

[0106]A biocompatible pregelatinized modified starch is pregelatinized hydroxyethyl starch. After the original starch (tapioca starch) is etherified and denatured to make hydroxyethyl starch, the hydroxyethyl starch is processed by roller drying method. Starch pre-gelatinization and denaturation to make pre-gelatinized hydroxyethyl starch, and then put the pre-gelatinized hydroxyethyl starch raw material in a boiling machine at 40-50°C, add distilled water, and undergo coagulation, pelleting, and sieving. Pregelatinized hydroxyethyl starch 88#*, molecular weight 10,000-500,000, particle size 10-1000 μm, and starch granules with a particle size of 30-500 μm account for not less than 95% of the total starch granules, particle size Preferably, it is 50 to 500 μm.

Embodiment 3

[0108] A biocompatible pregelatinized modified starch, which is pregelatinized carboxyethyl starch. After the original starch (potato starch) is etherified and denatured to make carboxyethyl starch, it is pregelatinized and denatured by roller drying method Pre-gelatinized carboxyethyl starch is made, and then the pre-gelatinized carboxyethyl starch raw material is placed in a boiling machine at 40-50°C, distilled water is added, and pre-gelatinized starch is made through coagulation, pelletizing and sieving. Carboxyethyl starch, the molecular weight is 15,000-2,000,000, the particle size is 10-1000 μm, and the starch granules with a particle size of 30-500 μm account for not less than 95% of the total starch granules, and the particle size is preferably 50-500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com