Spin forming mandrel with transversal inner rib component

A spinning forming and component technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult demolding, difficult design and application of core molds, and achieve easy machining, low manufacturing cost, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

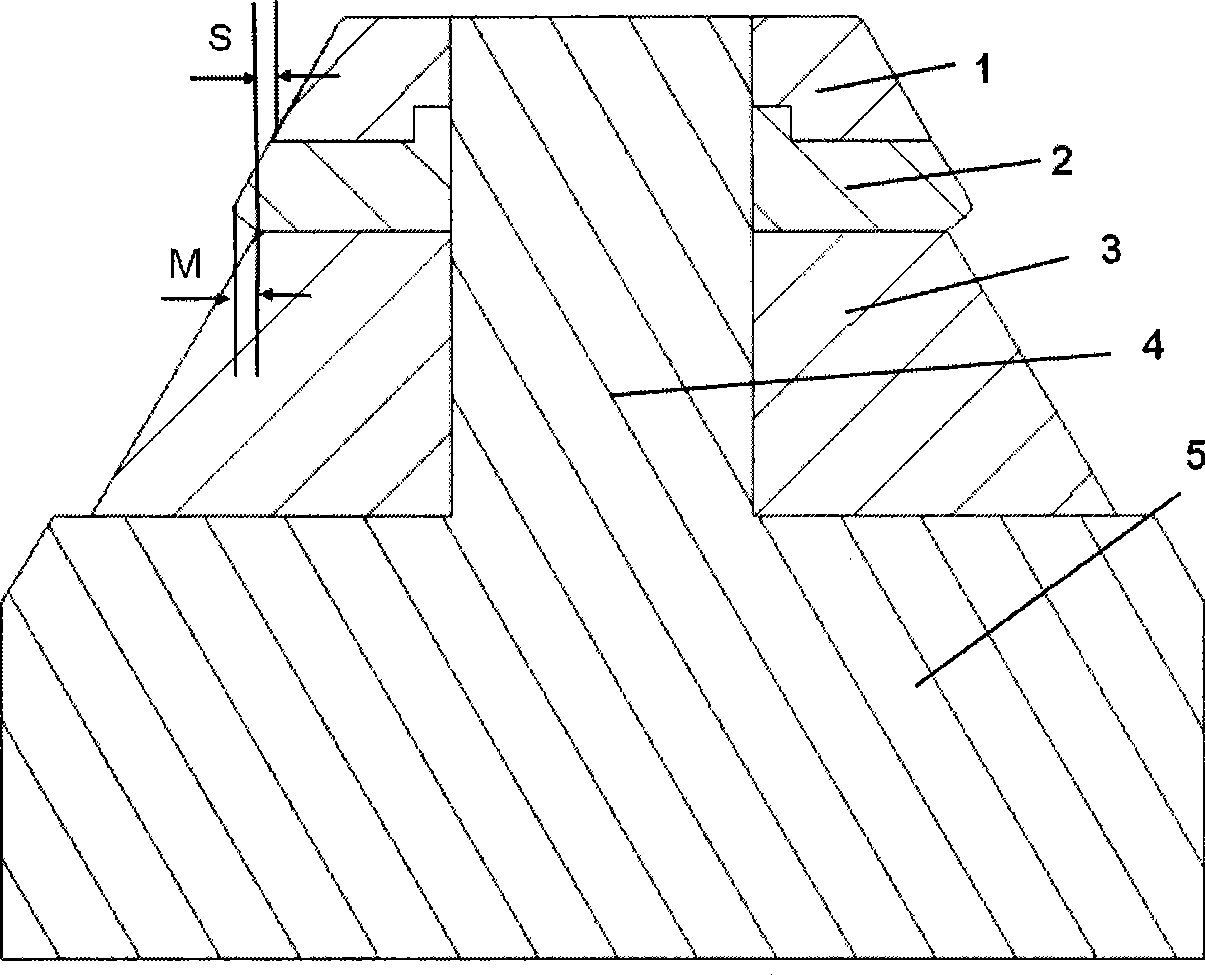

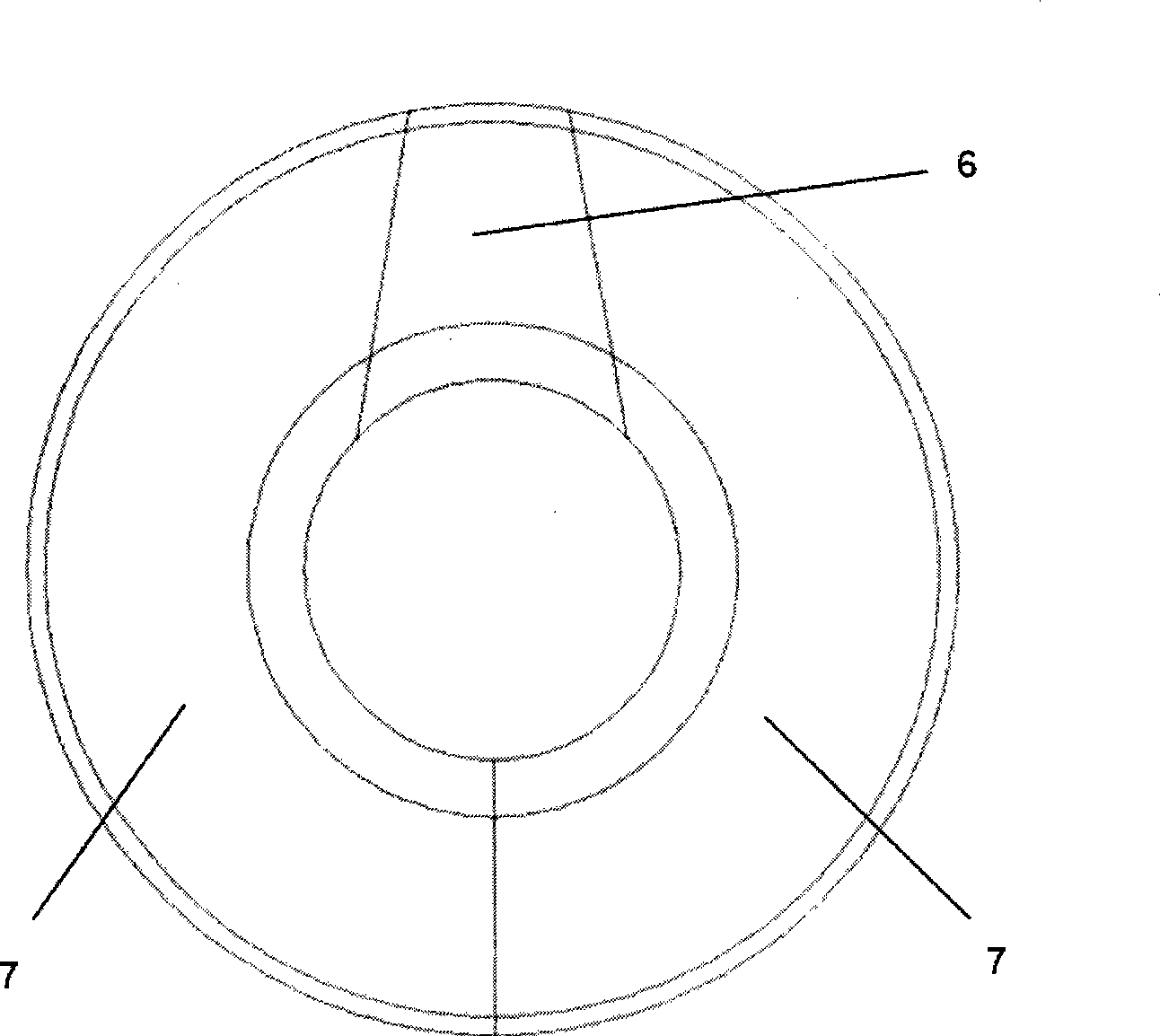

[0018] This embodiment is a horizontal and vertical combination split mold used in the spinning forming of a large thin-walled conical member with horizontal inner ribs. The initial thickness of the sheet in the test is 10mm, and the wall thickness of the conical part after forming is 2mm. The head height is 5mm, and the half cone angle of the mandrel is 30°. In the specific implementation, the whole mold consists of the top 1, splint 2, rib mold 3 and chuck 5 from top to bottom in order to form a tower (Fig. 6), and the longitudinal section of each part of the top 1, splint 2 and rib mold 3 is tapered.

[0019] This embodiment adopts the plan of combining horizontal and vertical splits, and divides the whole mold into top 1, splint 2, rib mold 3 and chuck 5, wherein the center holes of top 1, splint 2 and rib mold 3 are positioning holes; the top 1 , clamping plate 2, rib mold 3 and chuck 5 are all parts of a rotary body. There is an annular positioning groove at the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com