Denture forming machine for dental use

A technology for molding devices and dentures, applied in dental prosthesis, dentistry, dentures, etc., can solve the problems of expanding size, energy consumption, installation and moving difficulties, etc., to reduce the quantity, reduce the waste of resources, and overcome the trouble of maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] [55] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings, in which exemplary embodiments thereof are shown.

[0056] [56] First embodiment

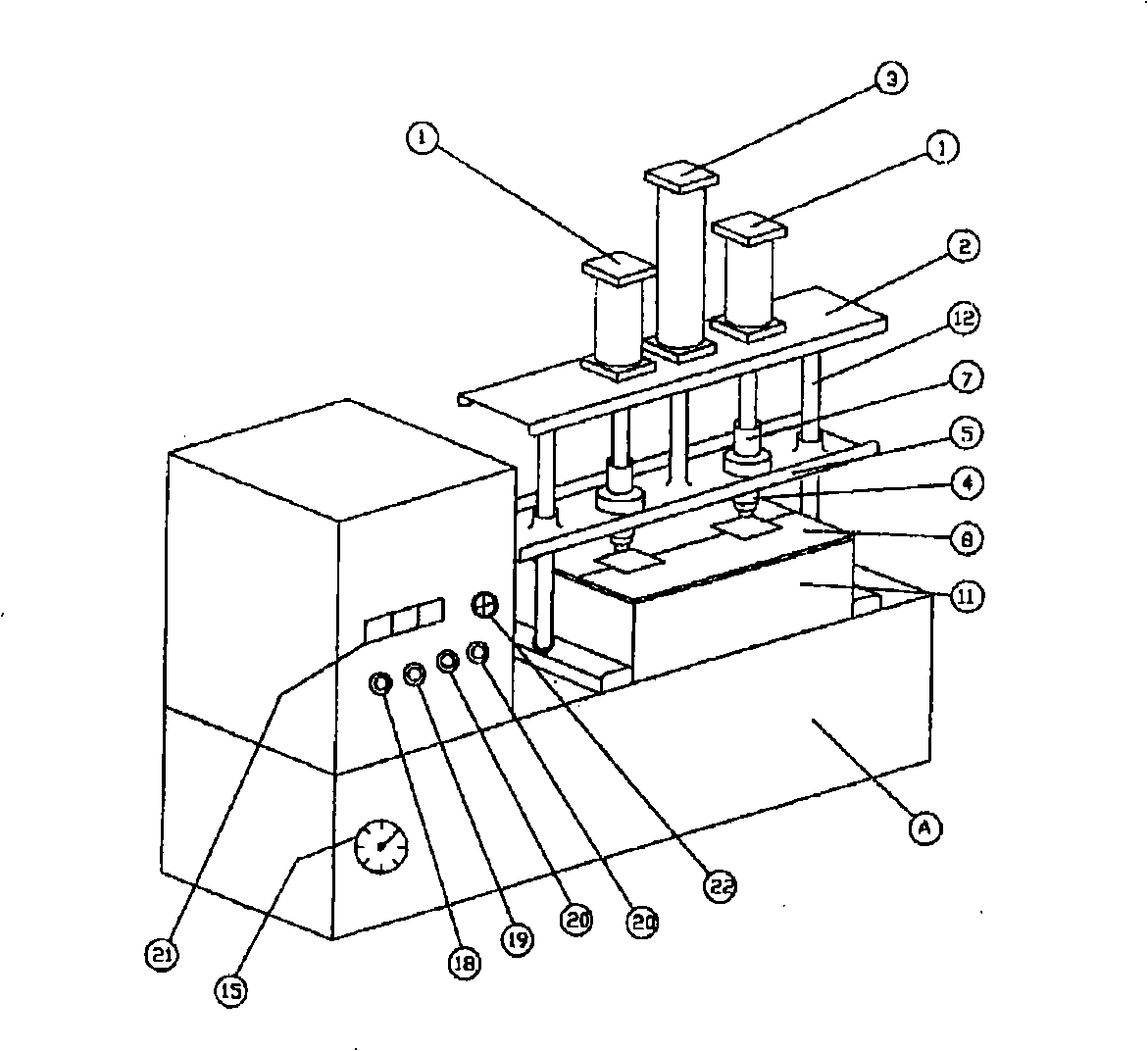

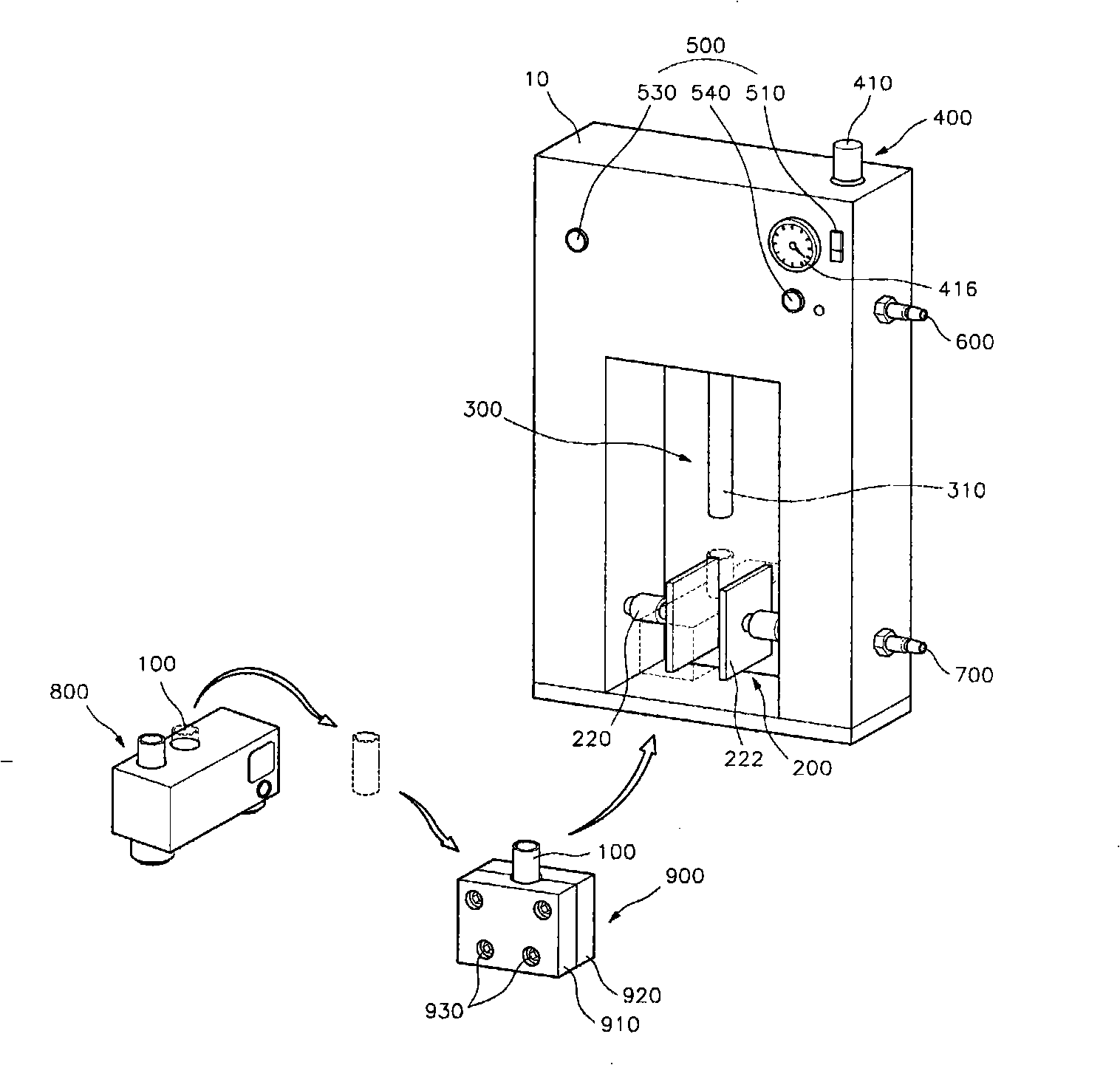

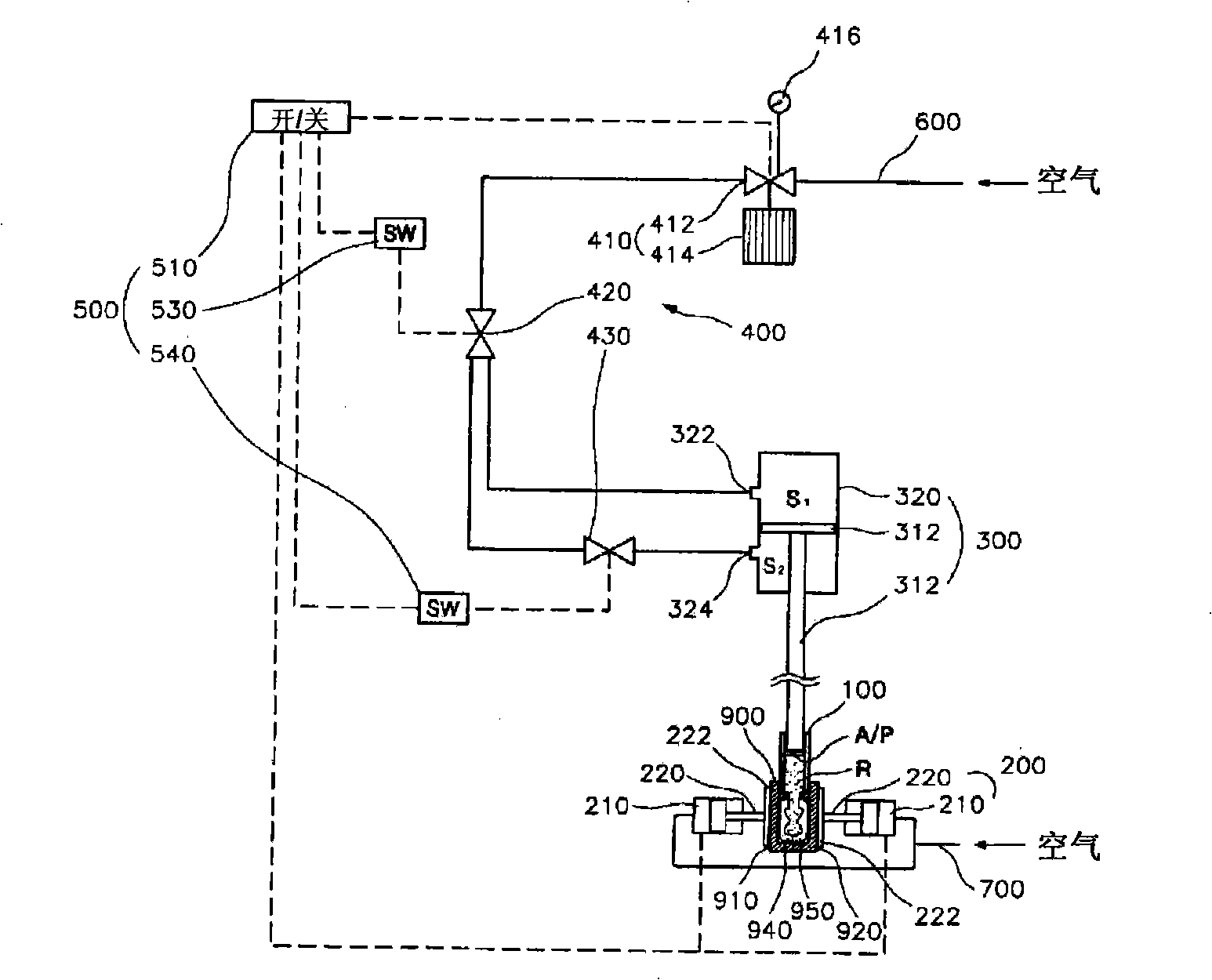

[0057] [57] figure 2 is a perspective view showing the overall external structure of a denture forming device for dental use according to the present invention, image 3 is a schematic view showing an air tube connection structure in a denture molding device for dental use according to the present invention.

[0058] [58] If figure 2 and image 3 As shown in , the denture forming device for dental use of the present invention generally includes a jig 200 , a pressing unit 300 , an air pressure adjusting unit 400 and a control unit 500 . These members 200, 300, and 500 are provided inside the casing 10, wherein the air pressure adjusting unit 400 is connected to the upper air pipe 600, and the clamp 200 is connected to the lower air pipe 700, so that the air pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com