Ambient temperature thermal energy and constant pressure cryogenic engine

A surrounding environment and engine technology, applied in variable displacement engines, machine/engines, reciprocating piston engines, etc., can solve problems such as harmful output of machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

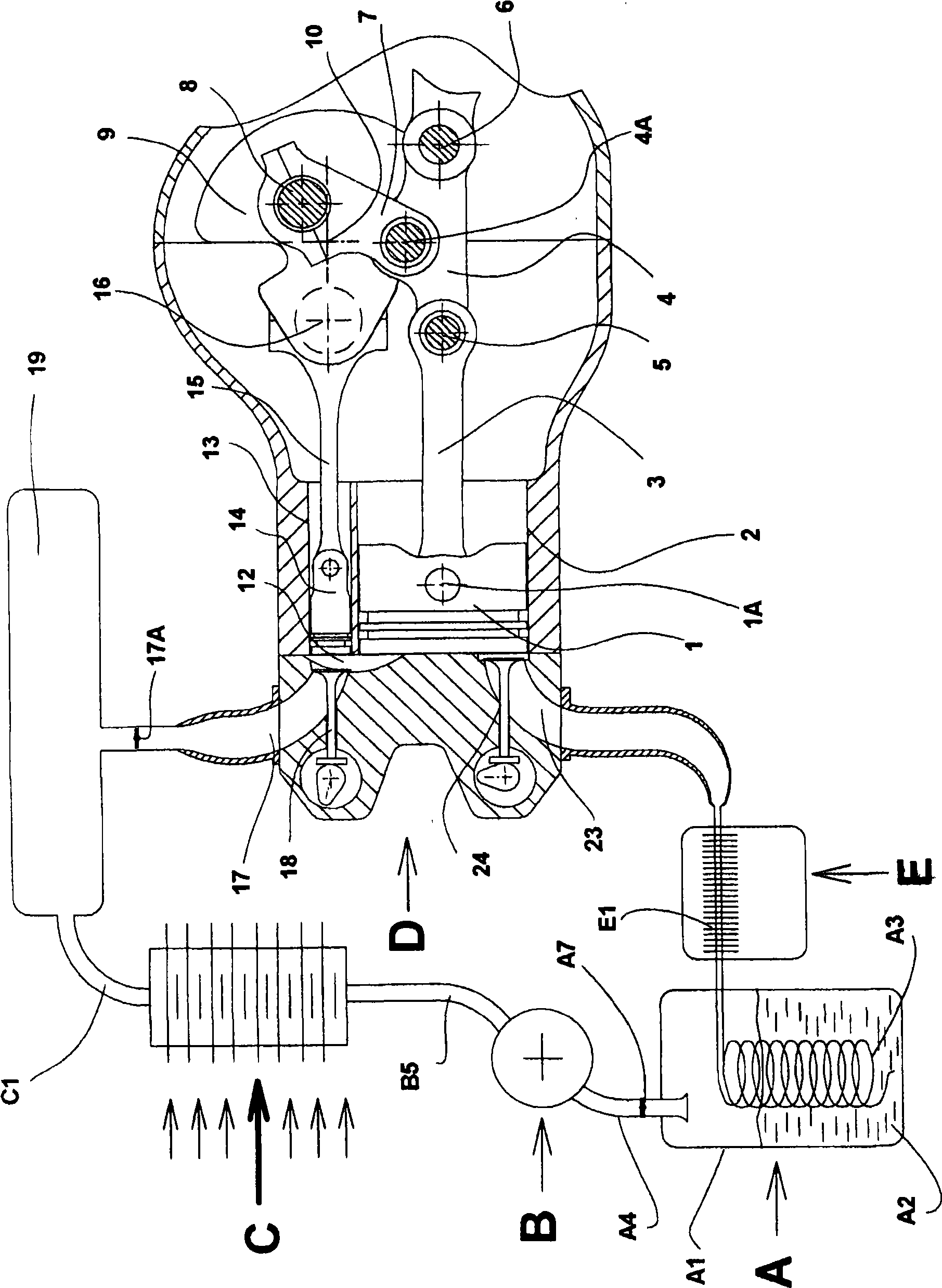

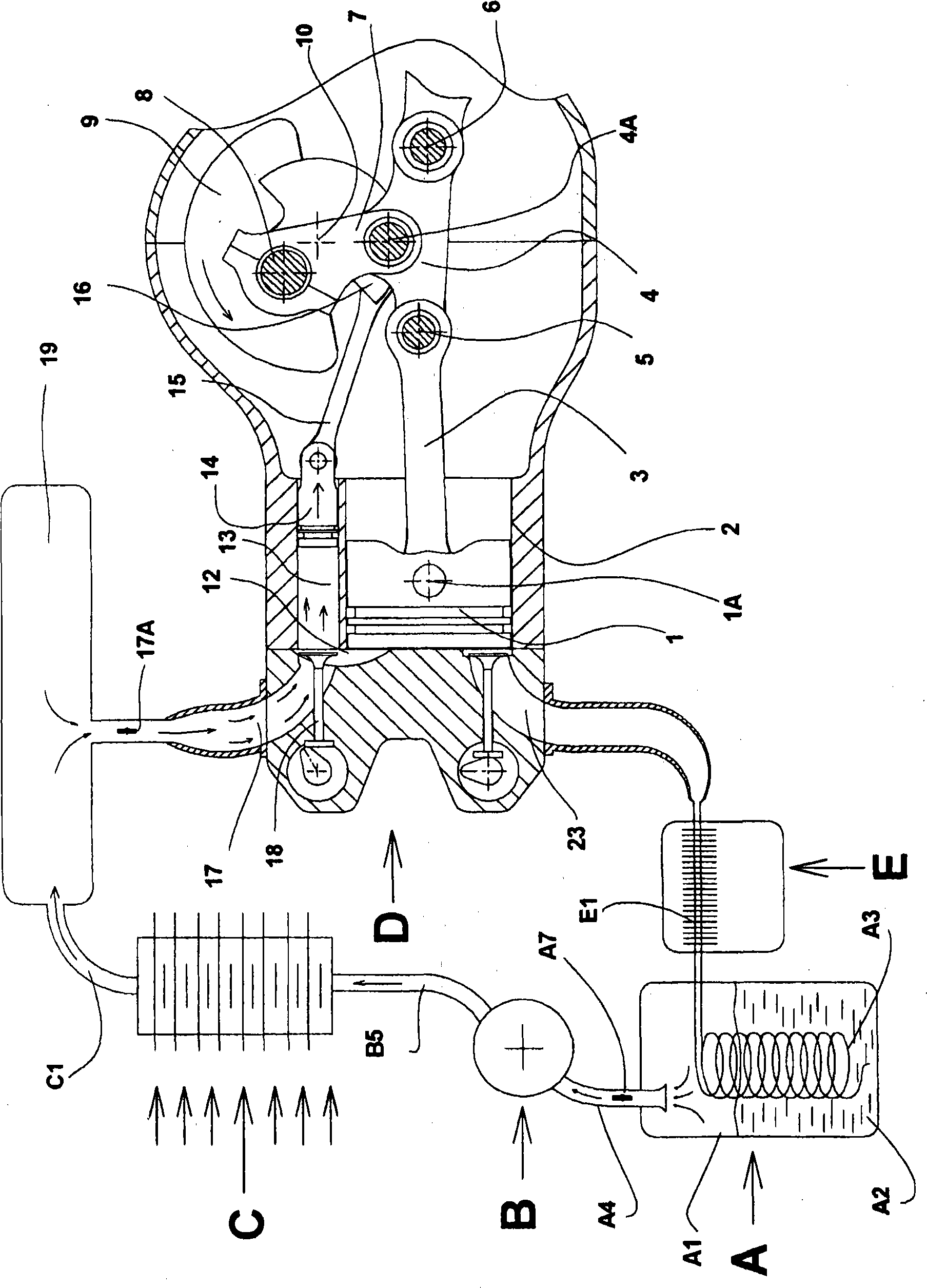

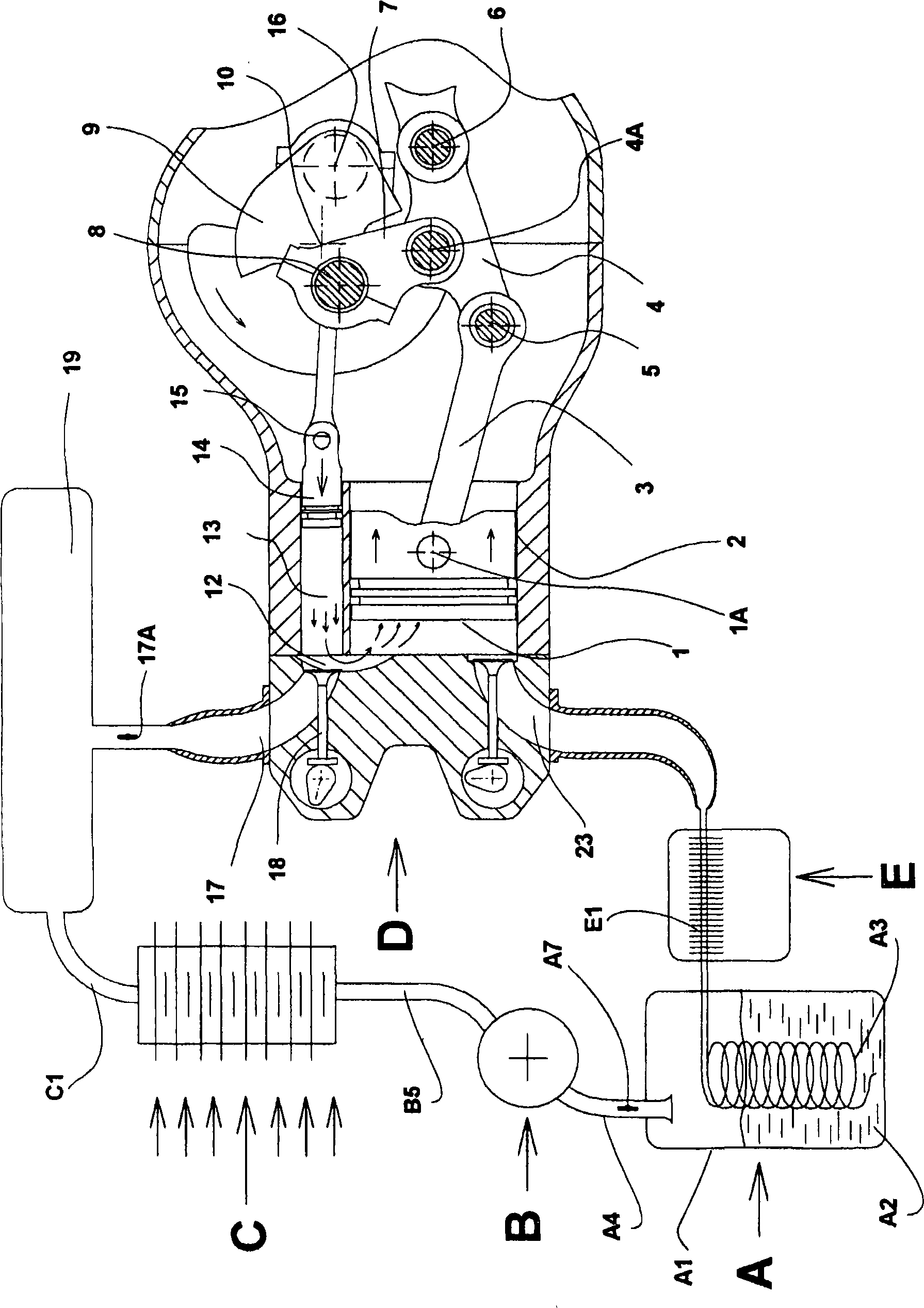

[0157] figure 1 It is a cross-sectional structural diagram of a thermal energy cryogenic engine at ambient temperature according to the present invention, which includes five main components: storage A for cryogenic fluid in liquid phase, very low temperature compressor B, gas / ambient air exchanger C , a work-doing volume release device D with an active chamber and a cryogenic machine E for cooling before liquefaction, in which can be seen an accumulator A1 in which a cryogenic fluid A2 in liquid phase is stored, which accumulator A1 comprises There is heat exchanger A3 for liquefaction and evaporation. The accumulator is connected to the inlet of the cryogenic compressor B through the pipe A4, the outlet of the cryogenic compressor B is connected to the cryogenic fluid / ambient air exchanger C through the pipe B5, and the cryogenic fluid / ambient air exchanger C It is itself connected via line C1 to a constant pressure expansion tank 19 which is itself connected to the inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com